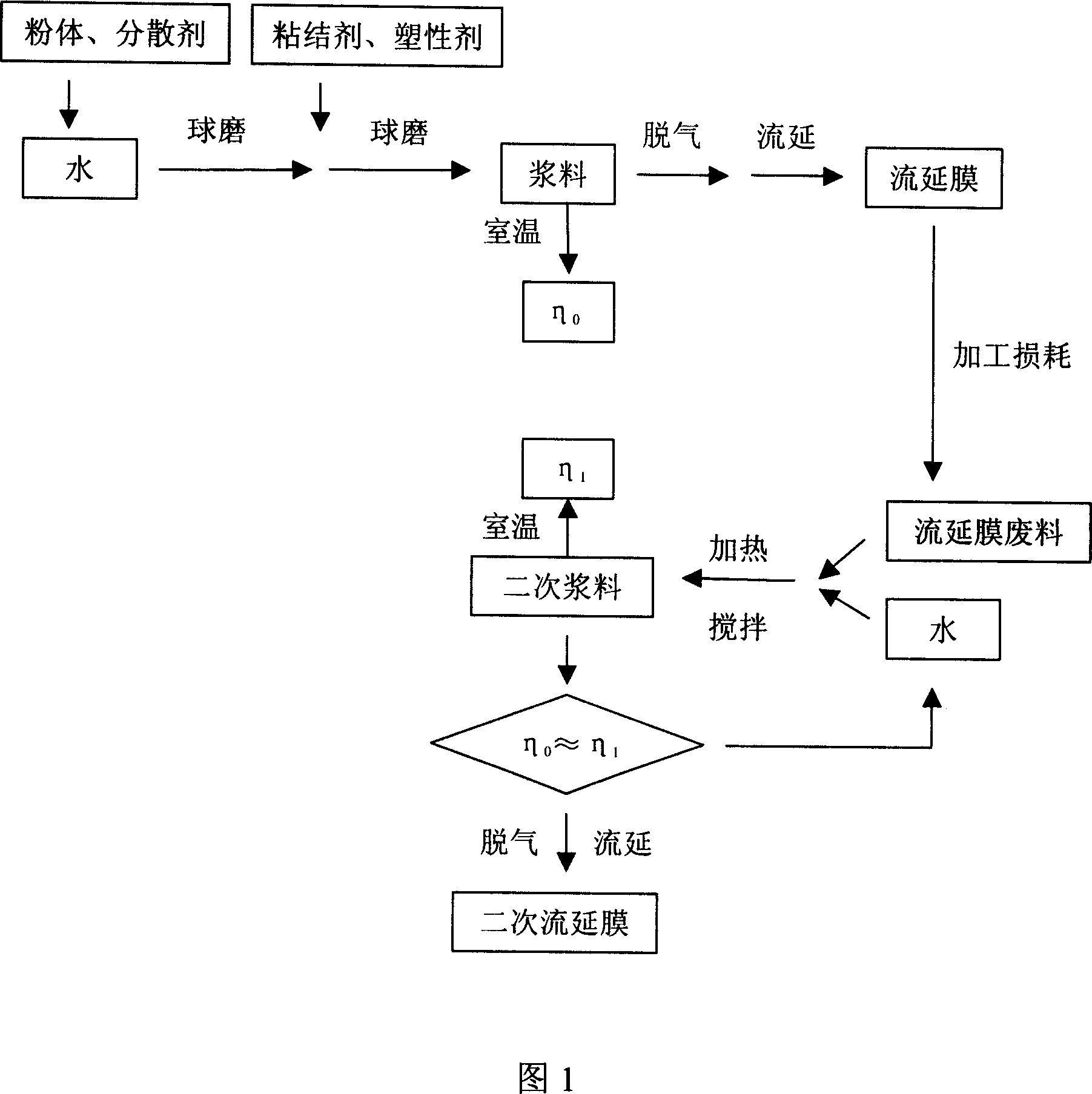

Method for recasting and reforming molded water-base casting film

A water-based casting and casting molding technology, applied in the field of casting molding technology, can solve the problems of recycling and utilization of water-based casting films, and achieve universality, easy control of conditions, cost and resource reduction. wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 100g of Al with an average particle size of 400nm 2 o 3 The powder was added to 25ml of water containing 2.0g of potassium polyacrylate (PAA-K) as a dispersant, and ball milled for 24h. 50 g of 12 wt % PVA solution and 7.2 g of 1,2-propanediol were added. Among them, the slurry binder / ceramic powder (X=0.06), plasticizer / binder (Y=1.2), (ceramic powder+binder+plasticizer) / solvent water (Z=1.64) . Continue ball milling for 24h, the slurry obtained 0 = 600 mPa·s. After the slurry is vacuum degassed, it is tape cast, and after natural drying, a cast film is obtained.

[0021] Put part of the cast film into the container, add a certain amount of water, and dissolve the cast film under strong stirring at 90-100°C, cool to room temperature, and ball mill for 12 hours to obtain a secondary slurry, and measure its viscosity η 1 = 600 mPa·s. The secondary slurry is vacuum-degassed and then tape-cast, and the vacuum degassing vacuum is 600-1000torr, and the secondary cast ...

Embodiment 2

[0023] 100g of Al with an average particle size of 400nm 2 o 3 The powder was added to 25ml of water containing 2.0g of potassium polyacrylate (PAA-K) as a dispersant, and ball milled for 24h. 50 g of 12 wt % PVA solution and 7.2 g of 1,2-propanediol were added. Among them, the slurry binder / ceramic powder (X=0.06), plasticizer / binder (Y=1.2), (ceramic powder+binder+plasticizer) / solvent water (Z=1.64) . Continue ball milling for 24h, the slurry obtained 0 = 600 mPa·s. The slurry was vacuum degassed and then tape casted for 30 minutes, and then naturally dried to obtain a cast film.

[0024] Put part of the cast film into the container, add a certain amount of water, and dissolve the cast film under strong stirring at 90-100°C, cool to room temperature, and ball mill for 12 hours to obtain a secondary slurry, and measure its viscosity η 1 = 580 mPa·s. The secondary slurry is vacuum-degassed, then tape-cast, and dried naturally to obtain a secondary cast film. The second...

Embodiment 3

[0026] 100g of Al with an average particle size of 400nm 2 o 3 The powder was added to 25ml of water containing 2.0g of potassium polyacrylate (PAA-K) as a dispersant, and ball milled for 24h. 58.3 g of 12 wt % PVA solution and 7.0 g of 1,2-propanediol were added. Among them, the slurry binder / ceramic powder (X=0.07), plasticizer / binder (Y=1.0), (ceramic powder+binder+plasticizer) / solvent water (Z=1.49) . Continue ball milling for 24h, the slurry obtained 0 =770mPa·s. After the slurry is vacuum degassed, it is tape cast, and after natural drying, a cast film is obtained.

[0027] Put part of the casting film into the container, add a certain amount of water, and dissolve the casting film under strong stirring at 90-100°C, cool to room temperature, and ball mill for 24 hours to obtain a secondary slurry, and measure its viscosity η 1 =760 mPa·s. The secondary slurry is vacuum-degassed, then tape-cast, and dried naturally to obtain a secondary cast film. The secondary me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com