Method for preparing biological organic fertilizer by using wool offcuts and Lycoris radiata extraction waste residue

A bio-organic fertilizer and scrap technology, which is applied in the preparation of organic fertilizers, the treatment of bio-organic parts, and organic fertilizers, can solve the problems of insufficient fermentation, incomplete treatment and decomposition, and secondary pollution of the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

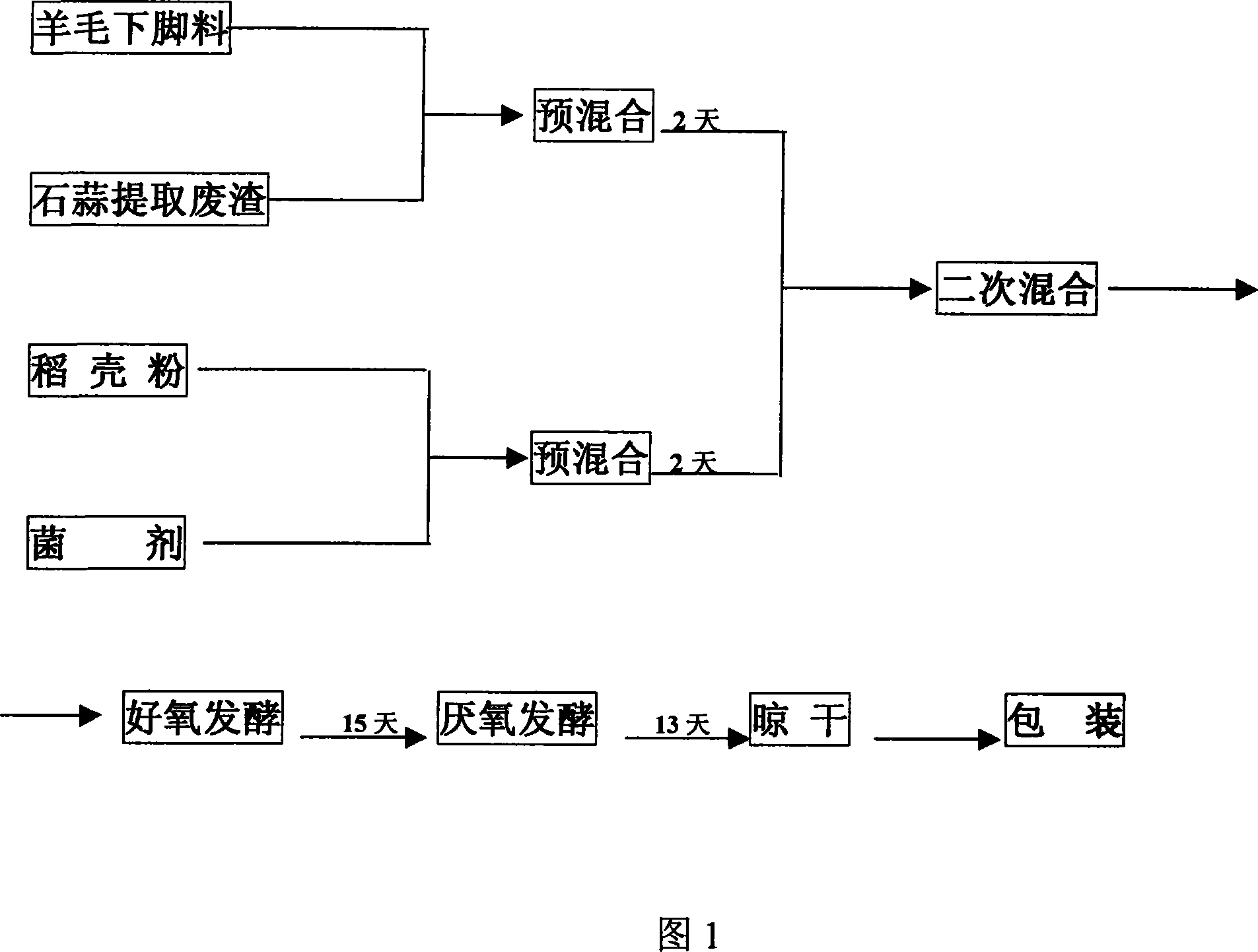

[0026] Referring to Fig. 1, the present invention is a method for making bio-organic fertilizer using wool leftovers and Lycoris extract waste residue. It uses wool leftovers and Lycoris extract waste residue as the main material, and uses straw powder, rice husk powder or / And rice bran as auxiliary materials, with fungus as composting fermentation agent, add water, after mixing, aerobic fermentation, anaerobic fermentation, dry and package. The production process is briefly described as follows:

[0027] 1. Premix

[0028] ①Wool leftovers and Lycoris extract waste residue were mixed at a ratio of 3:1 for two days to obtain premix I. Because the waste residue of Lycoris extract is 0.5% concentrated sulfuric acid, the short wool and oil in the wool scraps are hydrolyzed into keratin in two days under acidic conditions.

[0029] ②The straw and fungus are mixed with water at 15:2 for two days, and the water content is adjusted to 25% to obtain premix II. Straw powder, rice husk powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com