Method for producing infrared permeable black plastic products and application thereof

A technology of plastic products and infrared light, applied in the application of infrared photography, in the field of black plastics, can solve the problems of inability to transmit infrared photography, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

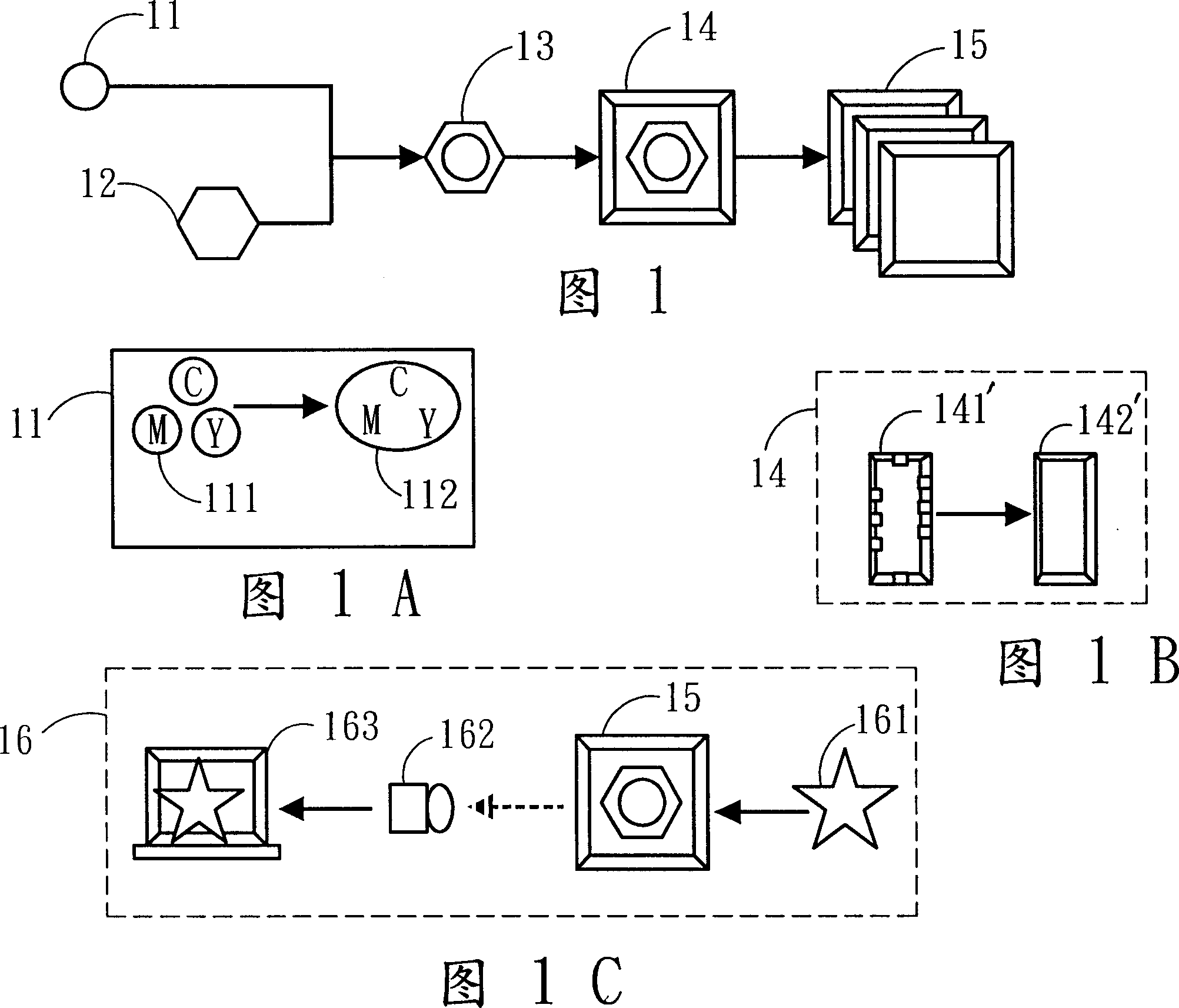

[0068] The main principles of the present invention are as shown in the following Figures 1 to 1C:

[0069] Please refer to FIG. 1 for a schematic diagram of processing a black plastic product that can transmit infrared light.

[0070] Among Fig. 1, mainly be that black pigment 11 and transparent resin 12 are mixed into black composite material 13, utilize the metallic mold 14 of an internal mold polishing again with black composite material 13, mold into a black plastic product 15.

[0071] Please refer to FIG. 1A which is a schematic diagram of the composition of the black colorant 11 .

[0072] In Fig. 1A, the composition method of black pigment 11 is to mix two or more single-color transparent pigments 111, or use a kind of fine carbon black powder to make it appear black pigment 112, the main purpose is to present black and absorb visible light.

[0073] Please refer to FIG. 1B which is a schematic diagram of the conditions of the metal mold 14 . Among Fig. 1 and Fig. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com