Brewing method for walnut white spirit

A walnut and liquor technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of unstable starch content, lack of nutritional value, bitter taste of the product, etc., and achieve the effect of protecting the liver, rich in aroma, and nourishing brain cells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

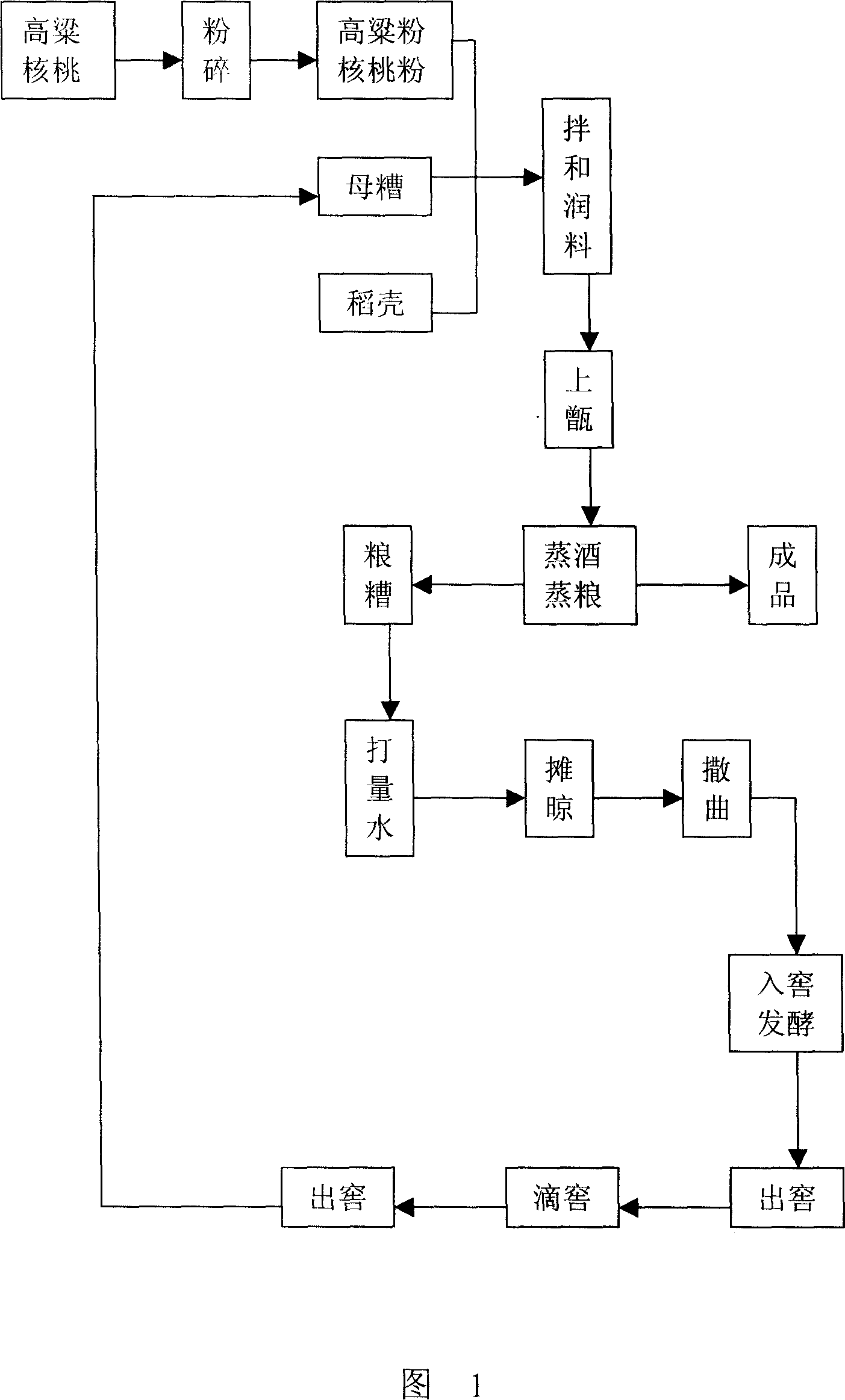

[0019] As shown in Figure 1, take 36kg of walnut fruit and 100kg of sorghum. 36kg of walnut fruit is sorted, washed, peeled and broken; 100kg of sorghum is sorted and washed; then crushed, mixed, retorted, steamed, spread out, measured water (18kg of water), sprinkled (sprinkled in the song) , the Daqu in the koji is 10wt%), fermenting in the cellar (the temperature in the cellar is 12°C-15°C, and the fermentation time in the cellar is 4 weeks), on the retort, steaming the wine, out of the retort, and making 35kg of finished walnut liquor.

Embodiment 2

[0021] Selected high-quality walnuts are peeled, and 50kg of the obtained walnuts are sorted, washed and broken, put into a pot according to the weight ratio of 5:2, plus 20kg of water, steamed at 100-120 ℃, steamed and brewed. The time is about 5 hours, and 30kg of walnut juice with a walnut content of 30-40wt% is distilled;

[0022] Blend 30kg of distilled walnut juice with 100kg of high-quality base wine;

[0023] After blending, the walnut wine is sealed and stored for 12 days, filtered and canned to obtain 130kg of finished walnut wine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com