Liquid transferring device

A delivery device and liquid technology, which is applied in transportation and packaging, liquid variable capacity machinery, fluid controllers, etc., can solve the problem of not considering the correctness of quantification, difficult sensors, mixed loading of reactors on substrates, and inability to achieve mixed Easy loading, correct positioning, etc., to achieve the effect of reducing the burden and reducing the number of switches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

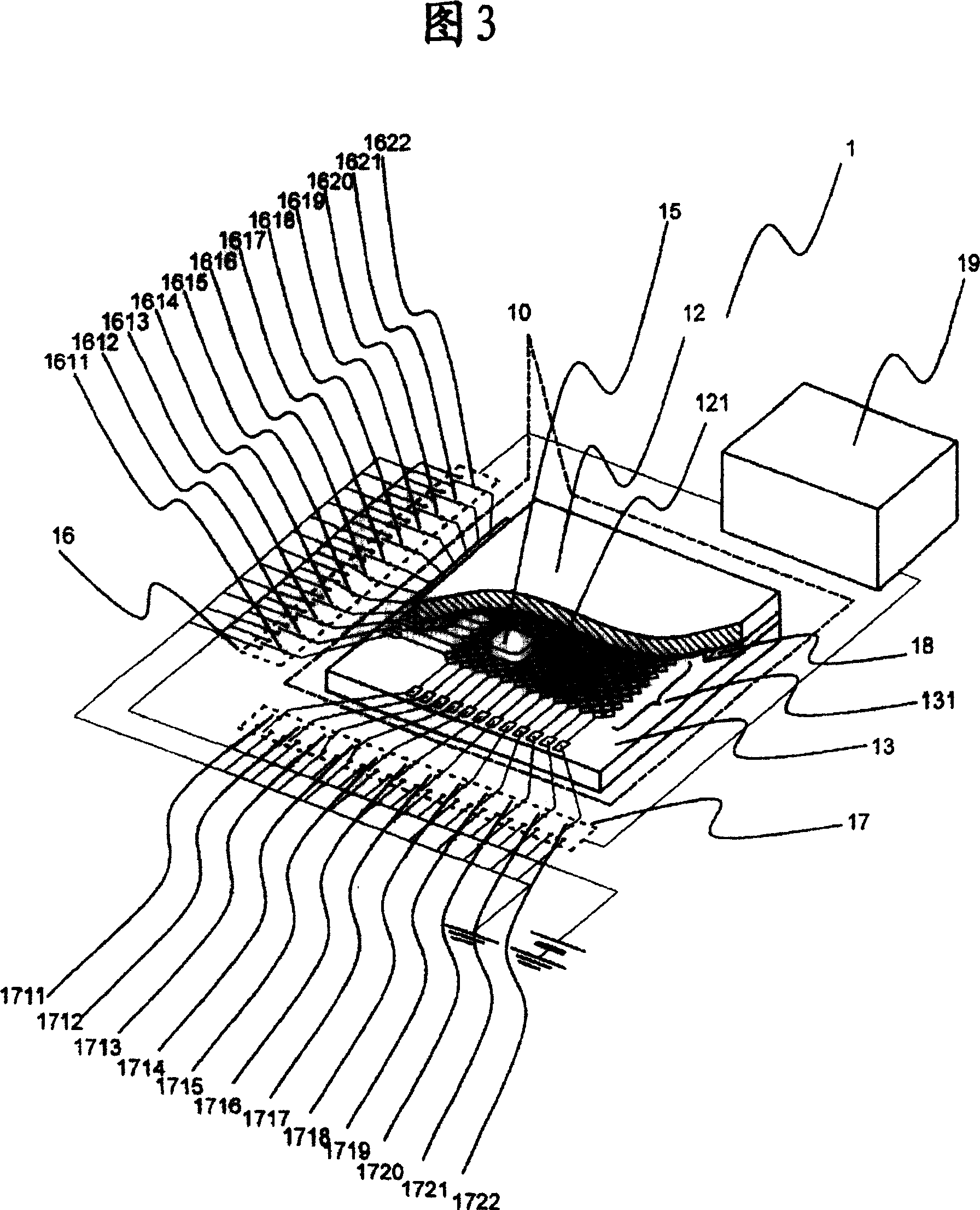

[0051] FIG. 3 is a diagram showing a configuration example of the liquid transport device of this embodiment. The liquid delivery device 1 of this embodiment consists of a liquid delivery element 10 holding a liquid droplet 15, a first axis voltage control device 16 and a second axis voltage control device 17 for controlling the voltage applied to the liquid delivery element 10, and The system device 19 is constituted by outputting signals for control to the first shaft voltage control device 16 and the second shaft voltage control device 17 .

[0052] The liquid conveying element 10 is constituted by arranging the upper substrate 12 and the liquid conveying substrate 13 having a plurality of rectangular electrodes 131 for driving in a gap formed by a spacer 18, and the conveyed liquid droplet is held in the gap between the two substrates. 15. The upper substrate 12 and the liquid transport substrate 13 are preferably arranged substantially parallel to each other. In the fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com