Controllable silicon trigger circuit of continuous mouse trapping boxes

A trigger circuit and mouse trap technology, applied in electronic switches, electrical components, animal traps, etc., can solve problems such as the inability to freely switch the working voltage, the inability to stop the alarm sound, and the error of the delay circuit of the mouse trap. Ease of implementation, low power consumption, and low component count

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

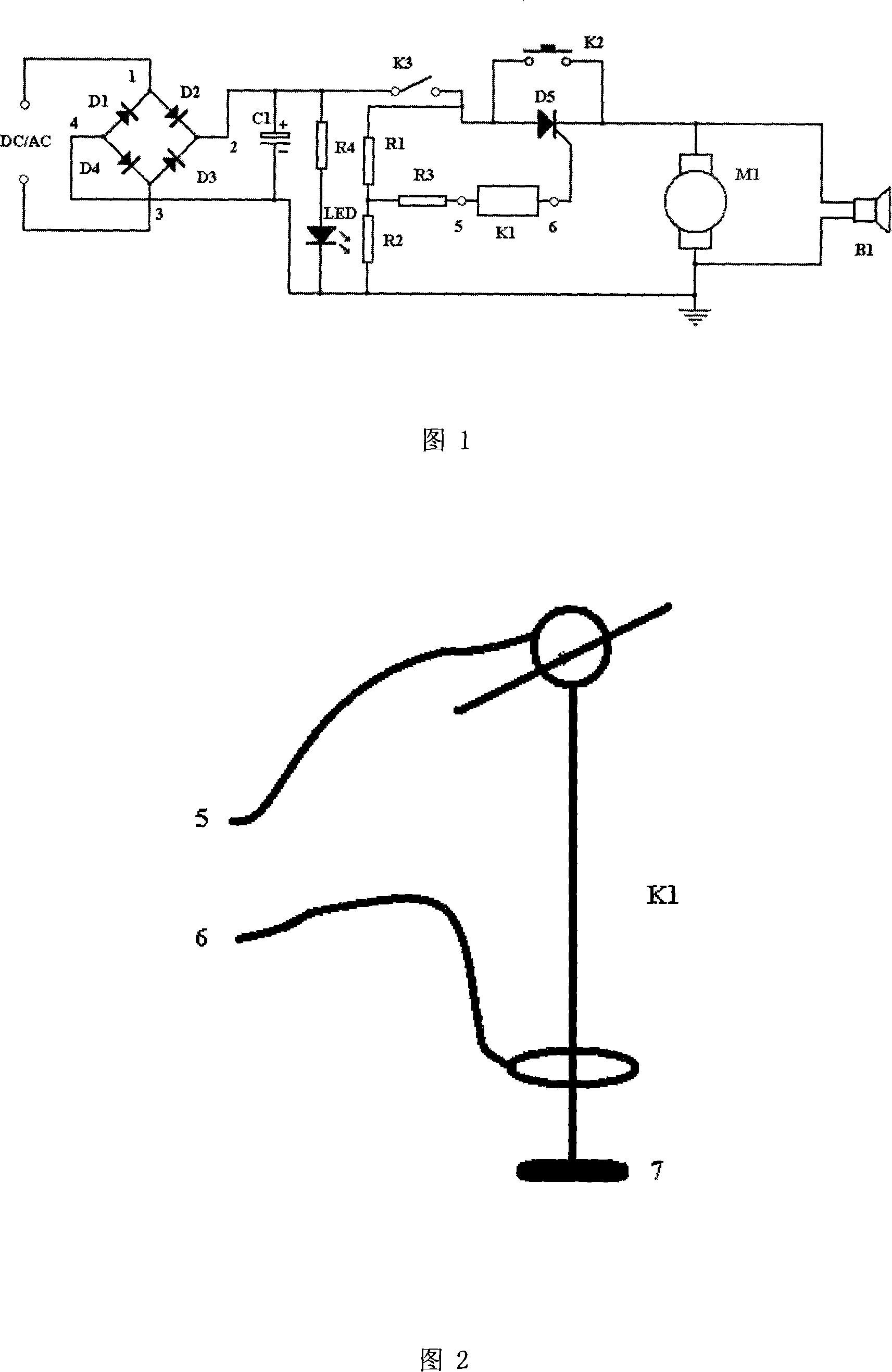

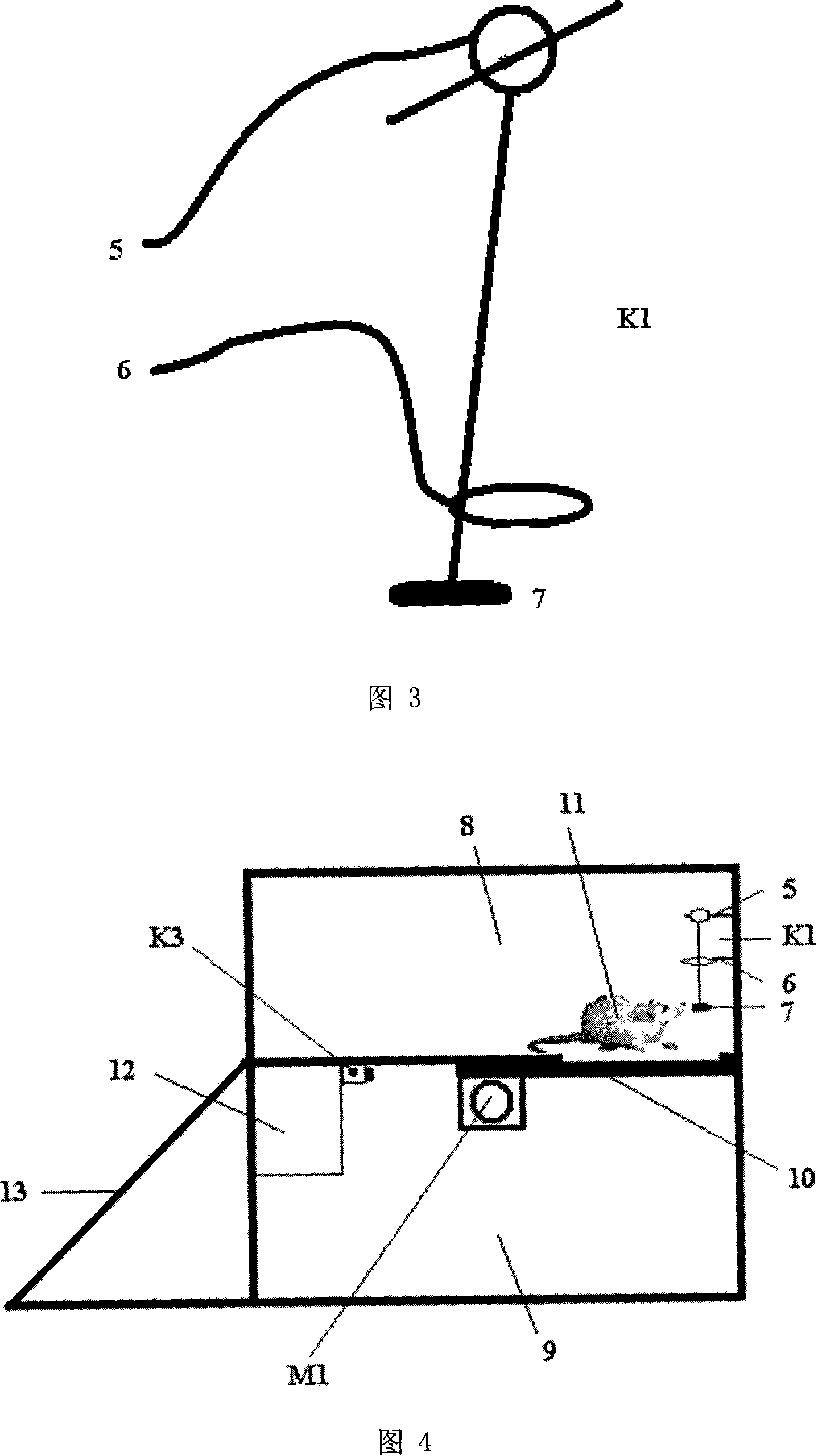

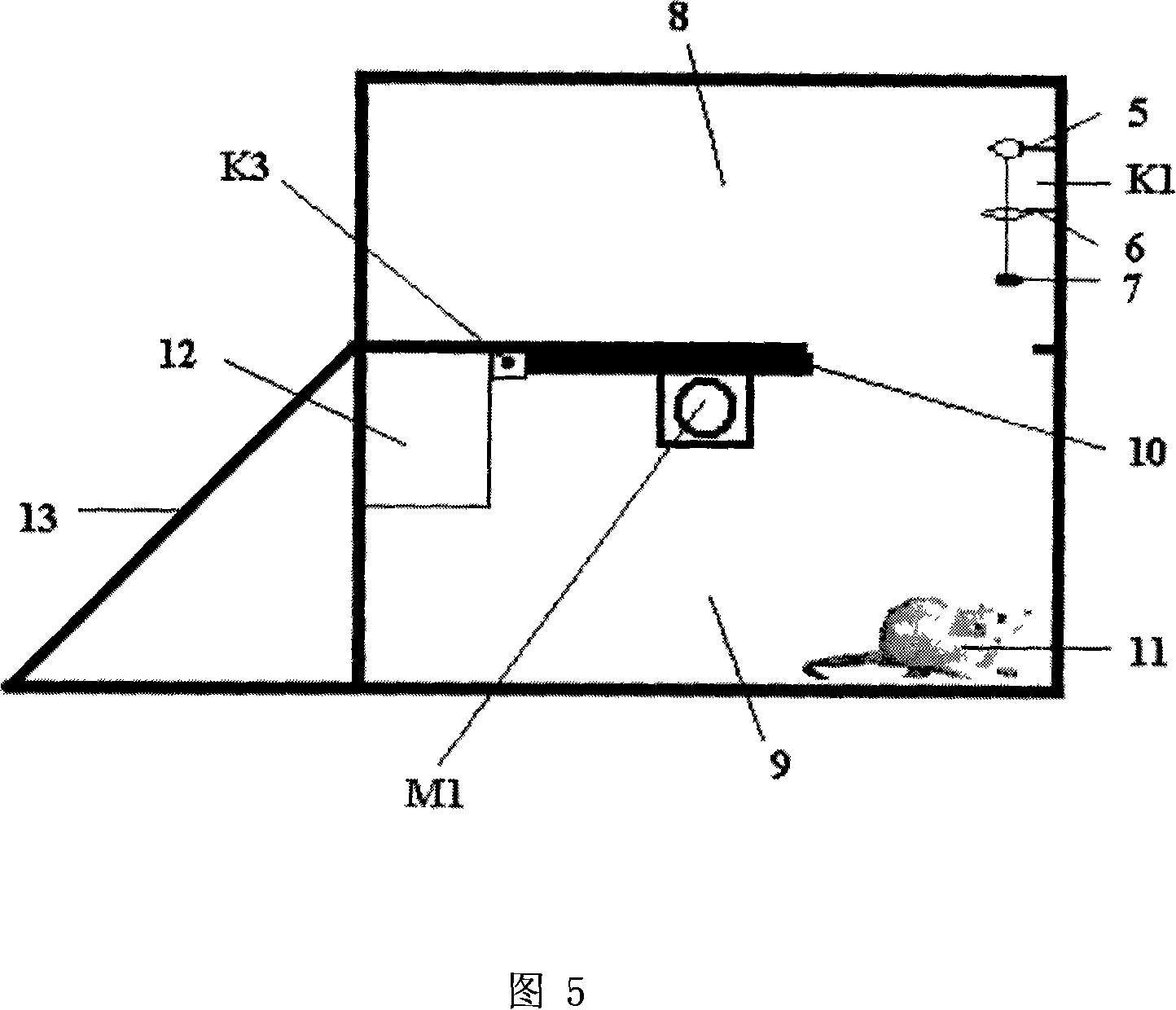

[0020] A thyristor trigger circuit 12 of a continuous mouse trap needs to be used in combination with a motor-driven continuous mouse trap. The cage 9 is closed, the upper floor mouse cage 8 is open, and there is a pumping plate 10 between the two layers. The step 13 is a closed surface of the lower floor mouse cage 9, which is obliquely connected to the front bottom edge of the upper floor mouse cage 8 and the lower floor mouse cage. Between the front bottom of the cage 9, the thyristor trigger circuit 12 contains the motor M1 and the working power supply. The thyristor trigger circuit 12 is installed in the lower squirrel cage 9, and the motor M1 draws the drawer by winding a steel wire around its rotating shaft when it is working. 10 is installed in the lower squirrel cage 9 in a manner of translation along the horizontal direction, and the negative output end of the working power supply is grounded. It is connected with the first power input terminal 1 and the second power...

Embodiment 2

[0022] Except for the following differences, this embodiment has exactly the same structure as Embodiment 1. It is characterized in that the thyristor trigger circuit 12 also includes a buzzer B1, and the positive pole and negative pole of the buzzer B1 are respectively connected to the positive terminal of the motor M1. Connect to the negative terminal.

Embodiment 3

[0024] Except for the following differences, this embodiment has the same structure as Embodiment 1. It is characterized in that the thyristor trigger circuit 12 also includes a normally open switch K2, which is a push button switch and is connected across the thyristor D5 between the anode and cathode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com