Azelnidipine medicinal composition and its preparing method

A technology of azelnidipine and its composition, which is applied in the field of pharmaceutical compositions containing azelnidipine, and can solve problems such as the decrease of dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

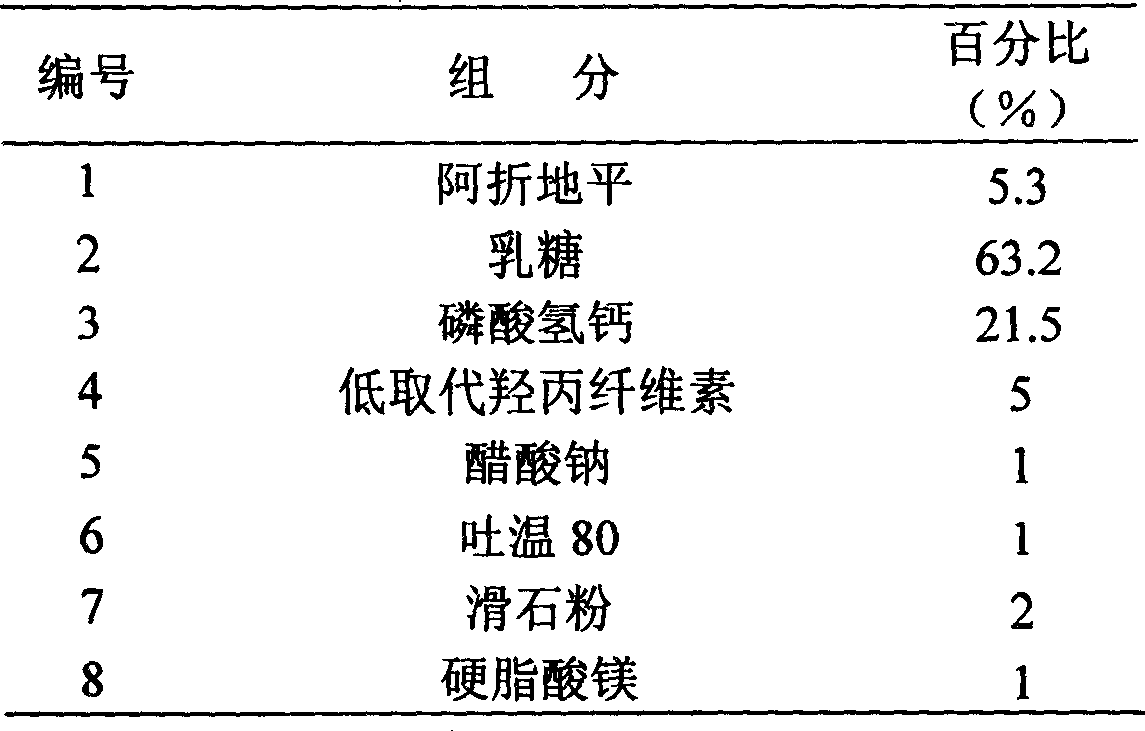

Embodiment 1

[0031]

[0032] Preparation Process:

[0033] 1. Azhedipine and calcium hydrogen phosphate pass through a 120-mesh sieve; talcum powder and magnesium stearate pass through a 60-mesh sieve; other auxiliary materials pass through a 80-mesh sieve for later use;

[0034] 2. After weighing the prescribed amount of Azendipine and lactose and mixing evenly, dissolve the prescribed amount of Tween 80 in a small amount of water (concentration is about 23%) and add it to mix evenly, then mix with calcium hydrogen phosphate, low-substituted hydroxypropyl fiber Sodium acetate and sodium acetate are mixed homogeneously according to the principle of increasing in equal amounts, to obtain mixture I;

[0035] 3. Mixture I uses water as a wetting agent to make a soft material, and passes through a 18-mesh sieve to granulate. Wet granules are blast-dried in an oven at 50°C, and sieved with a 24-mesh sieve after completion;

[0036] 4. Add talcum powder and magnesium stearate in the prescri...

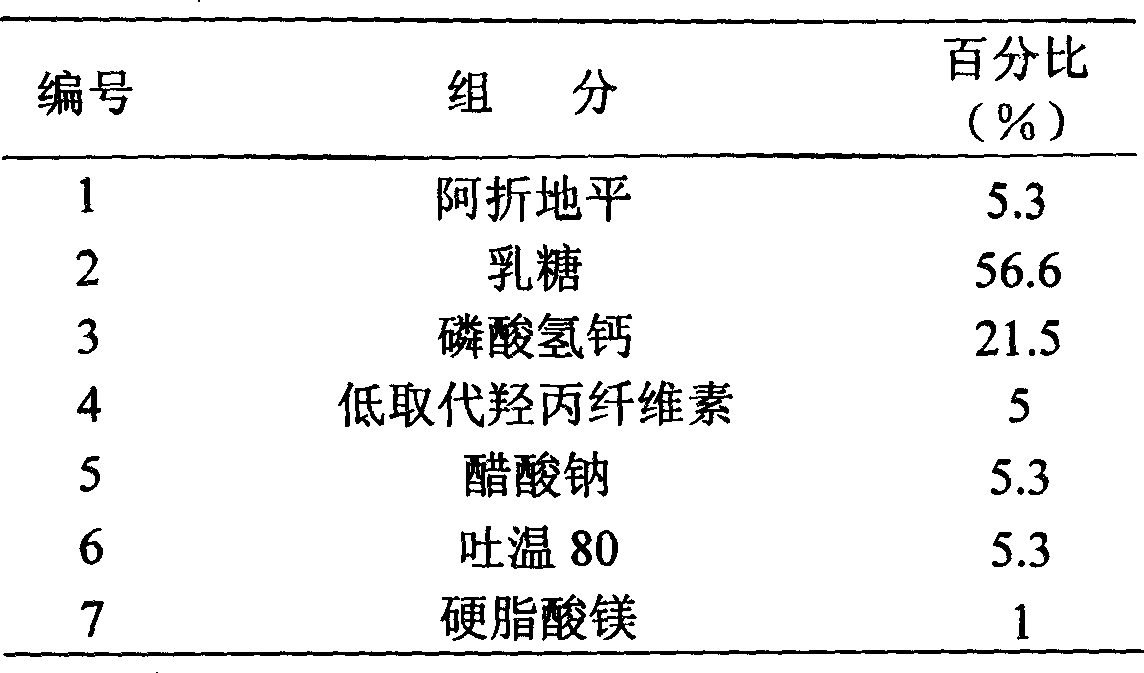

Embodiment 2

[0039]

[0040] Preparation Process:

[0041] 1. Azhedipine and calcium hydrogen phosphate are passed through a 120-mesh sieve; magnesium stearate is passed through a 60-mesh sieve; other auxiliary materials are passed through a 80-mesh sieve for later use;

[0042] 2. Weigh the prescribed amount of Azendipine and mix it with lactose evenly, dissolve the prescribed amount of Tween 80 in a small amount of water (concentration is about 23%) and add it to mix evenly, then mix with calcium hydrogen phosphate, low-substituted hydroxypropyl cellulose Mix uniformly with sodium acetate according to the principle of equal addition, to obtain mixture I;

[0043] 3. Mixture I uses water as a wetting agent to make a soft material, and passes through a 18-mesh sieve to granulate. Wet granules are blast-dried in an oven at 50°C, and sieved with a 24-mesh sieve after completion;

[0044] 4. Add the prescribed proportion of magnesium stearate to the dried granules, and mix well;

[0045...

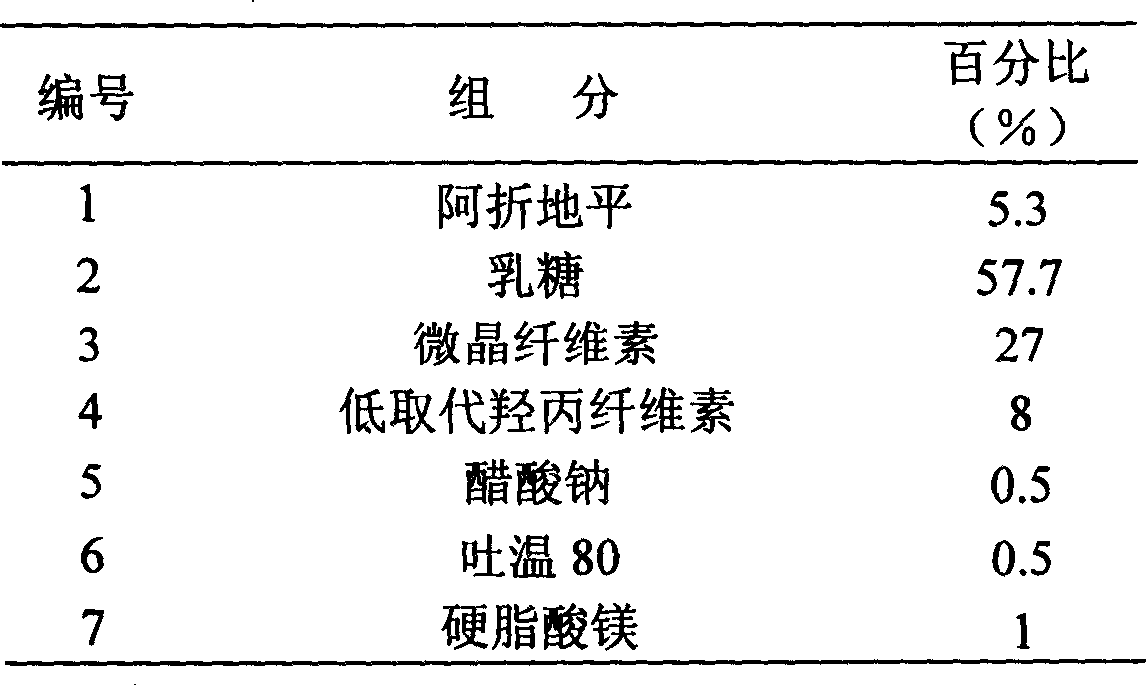

Embodiment 3

[0047]

[0048] Preparation Process:

[0049] 1. Azhedipine is passed through a 120-mesh sieve; magnesium stearate is passed through a 60-mesh sieve; other excipients are passed through a 80-mesh sieve for later use;

[0050] 2. Weigh the prescribed amount of Azendipine and mix it evenly with lactose, dissolve the prescribed amount of Tween 80 in a small amount of water (concentration is about 23%) and add it to mix evenly, then mix it with microcrystalline cellulose, some low-substituted hydroxypropyl Cellulose and sodium acetate are mixed homogeneously according to the principle of increasing in equal amounts to obtain mixture I;

[0051] 3. Mixture I uses water as a wetting agent to make a soft material, and passes through a 18-mesh sieve to granulate. Wet granules are blast-dried in an oven at 50°C, and sieved with a 24-mesh sieve after completion;

[0052] 4. Add the prescribed proportion to the dried granules, plus some low-substituted hydroxypropyl cellulose and ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com