Method and device for preventing aluminum tapping two-man ladle absorbing electrolyte

A technology of electrolyte and suction pipe, which is applied in the field of aluminum ladle to prevent electrolyte inhalation, can solve the problems of increasing the electrolyte cleaning workload in the mixing furnace, accelerating the damage of the lining of the mixing furnace, and not causing technical personnel, so as to prevent residue and prolong use Effects of lifespan and workload reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

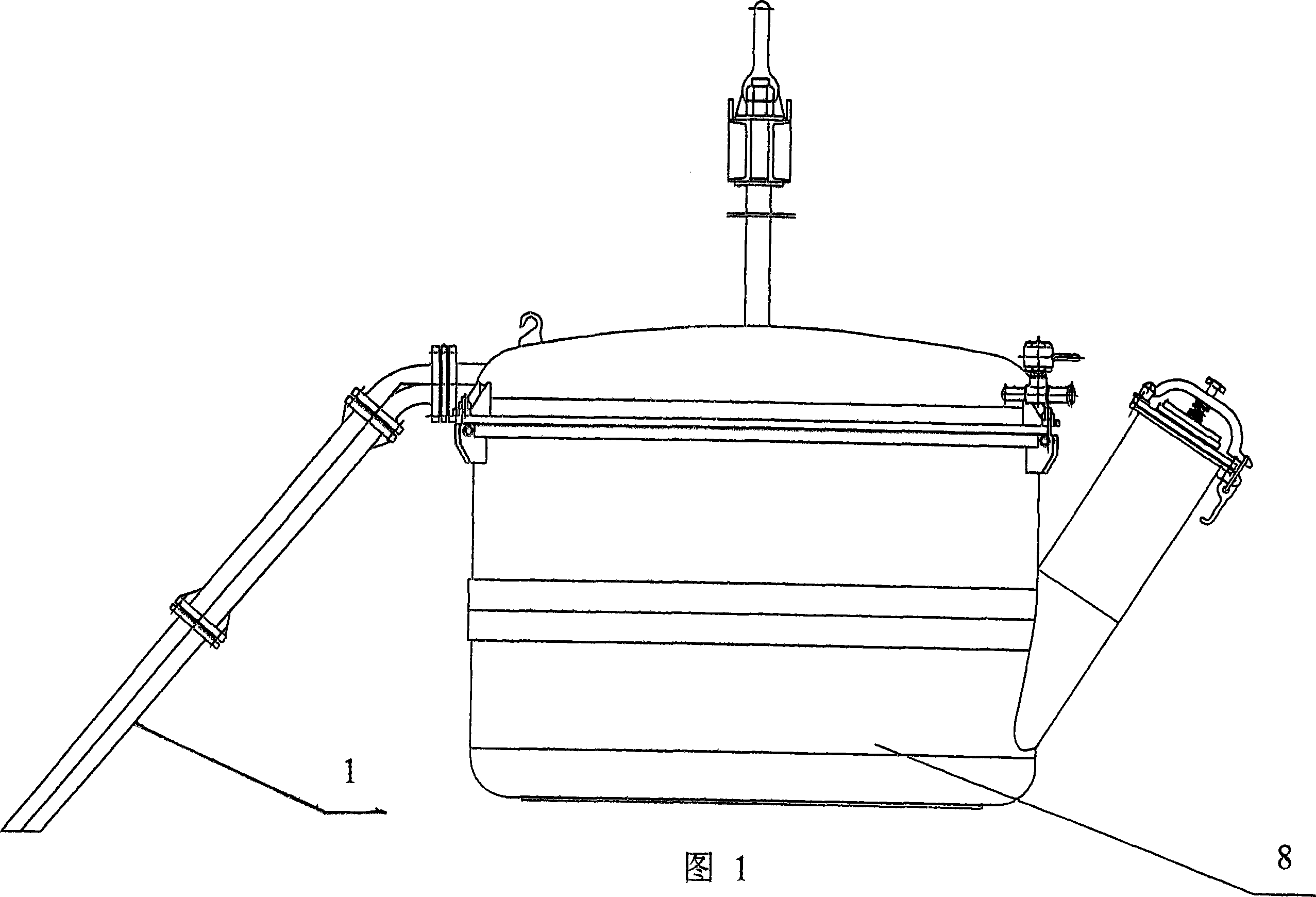

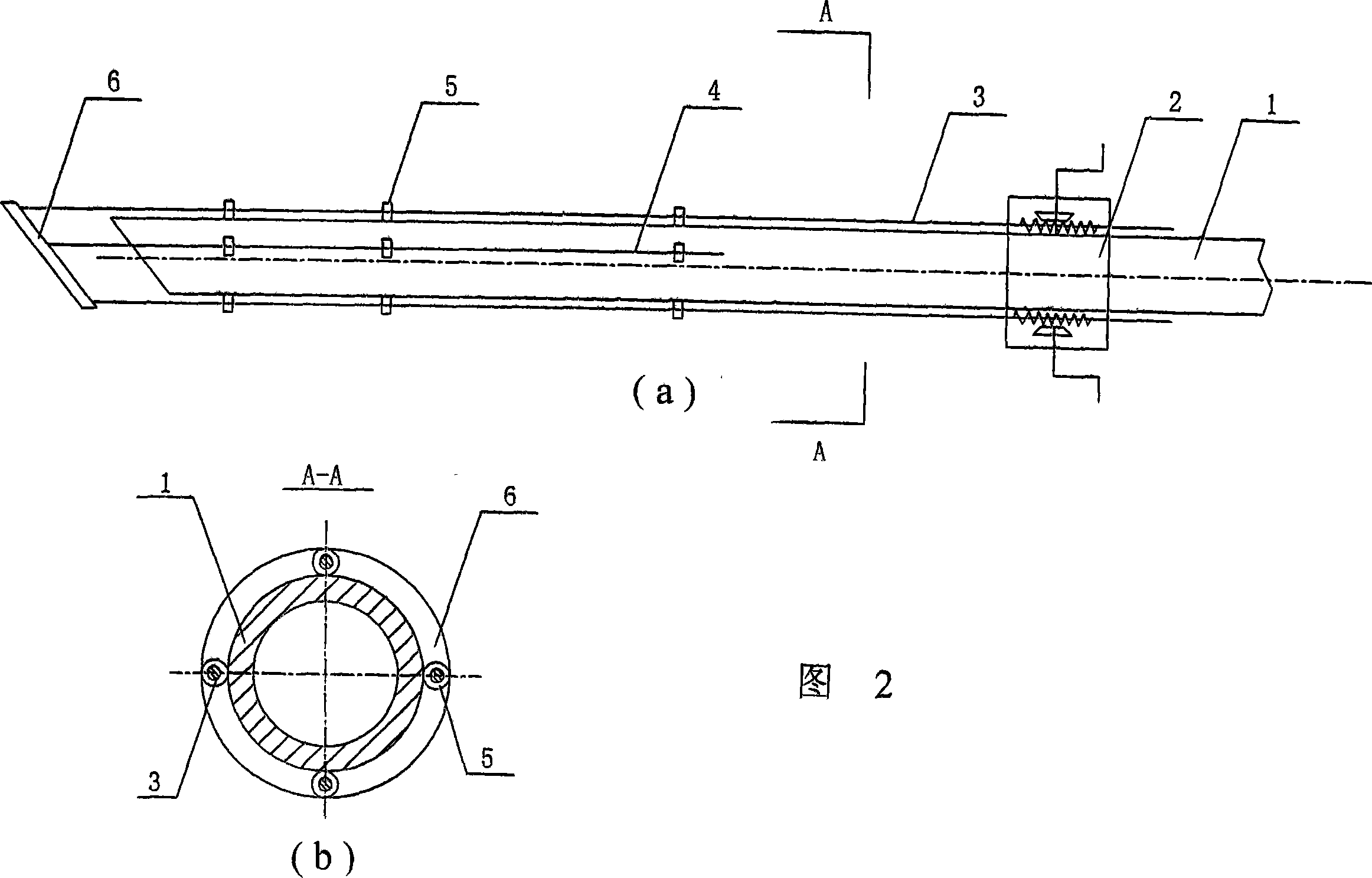

[0019] Example 1 Electrolyte operated anti-electrolyte inhalation device

[0020] In front of the mouth of the aluminum suction tube 1, a blocking plate 6 is set, and more than two pull rods 3 are installed on the edge of the blocking plate at the outer edge of the aluminum suction tube, and more than two sets of pull rod brackets 5 are installed on the outer wall of the aluminum suction tube. A group bracket consists of more than two brackets. Pull rod passes pull rod support, and it is near the root of suction aluminum bag 8, and car has the external thread that cooperates with drive unit 2 internal threads. The bottom of the blocking plate is also provided with a positioning rod 4, which further ensures that the pull rod can slide back and forth in the pull rod bracket smoothly, and promotes the opening and closing of the blocking plate.

Embodiment 2

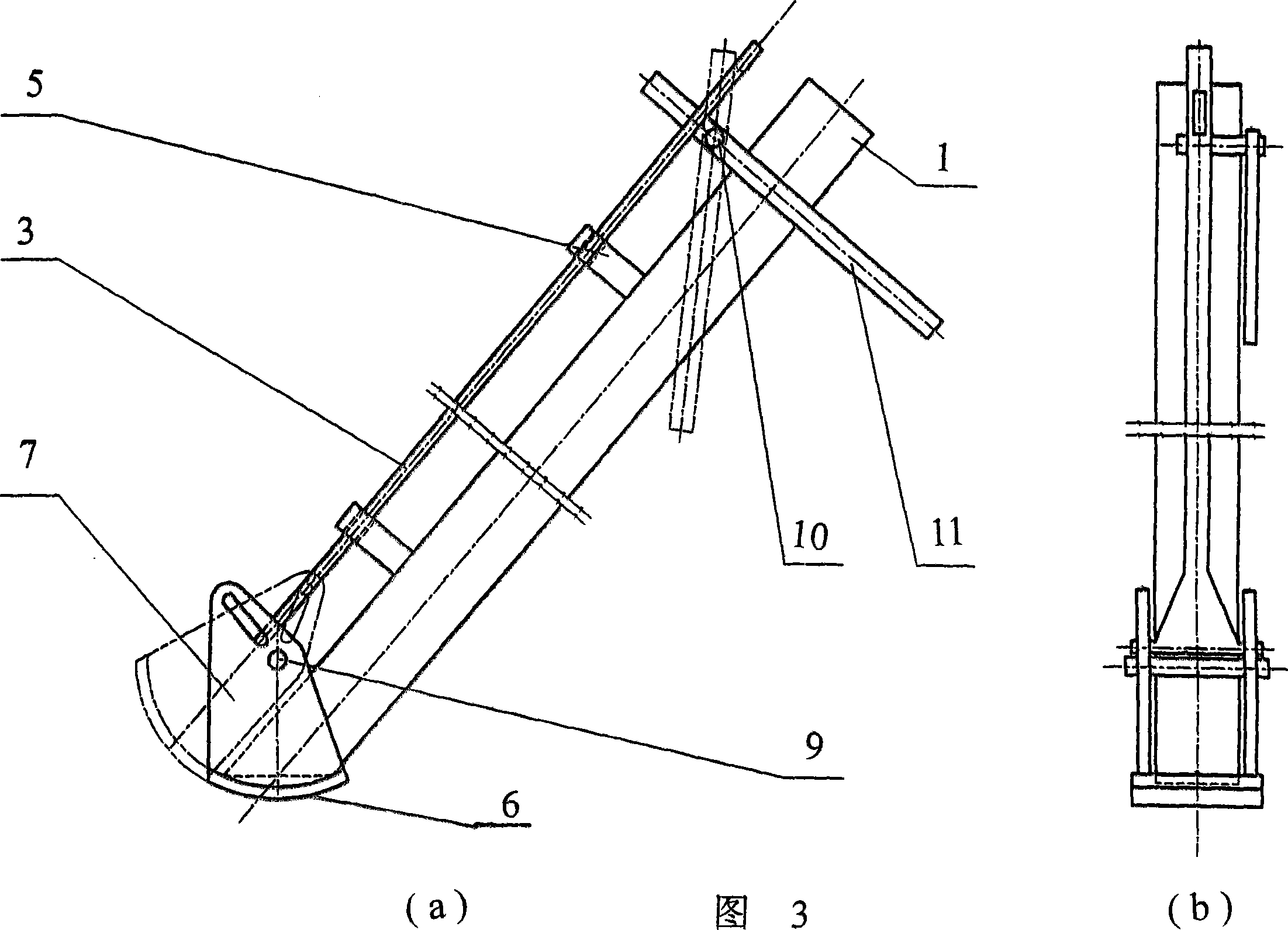

[0021] Example 2 Manually Operated Electrolyte Inhalation Prevention Device

[0022] In front of the mouth of the aluminum suction pipe 1, a blocking plate assembly 7 is arranged, and the blocking plate 6 itself is arc-shaped, and matched with this, the side of the aluminum suction pipe mouth is also arc-shaped, and the curved surfaces of the two match everywhere. The blocking plate assembly is provided with a blocking plate rotary shaft 9, with the rotary shaft as the center, a pull rod 3 is arranged on the other side opposite to the center of gravity of the blocking plate assembly; and more than one sliding bracket 5 is provided on the outside of the aluminum suction tube. Covered in the bracket, the other end is provided with a handle 11 and a handle rotary shaft 10 which are hinged with it. When the handle is moved, the pull rod moves forward and backward with the handle rotary shaft as the axis, and then the blocking plate assembly is driven around The rotary shaft of the...

Embodiment 3

[0023] Example 3 Anti-electrolyte inhalation device for automatic operation

[0024] In front of the aluminum suction pipe 1, a rectangular blocking plate 3 is set, and the corresponding front end section of the suction pipe is also changed into a rectangle. Blocking plate and the thick splint welded on its both sides form reversible blocking plate assembly 7, splint itself is the gravity push plate 12 that profile is arc, and eccentric rotary shaft sleeve 13 is arranged on the push plate. And be equipped with rotary shaft 9 at suction pipe outer wall. Usually, the blocking plate assembly rotates around the rotary shaft under the action of eccentric gravity to close the suction pipe; when aluminum is to be tapped, although the suction pipe enters the electrolyte layer, the blocking plate assembly is still closed under the action of eccentric gravity because the gravity push plate has not touched the bottom of the tank Nozzle. When the suction pipe continues to descend throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com