Chain-drive mechanism of heating machine

A technology of chain drive and heating machine, which is applied in transmission devices, mechanical equipment, belts/chains/gears, etc., which can solve problems such as waste of space, troubles in enterprise production, and increase in manufacturing costs, so as to reduce chain vibration and save heating Effects of improving energy and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

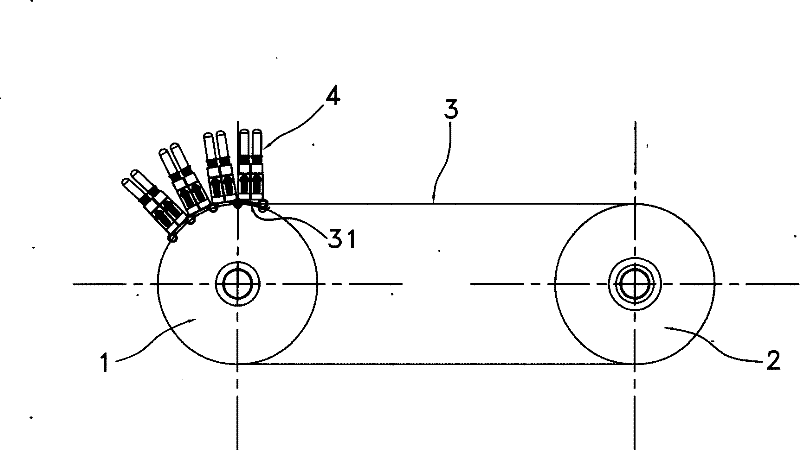

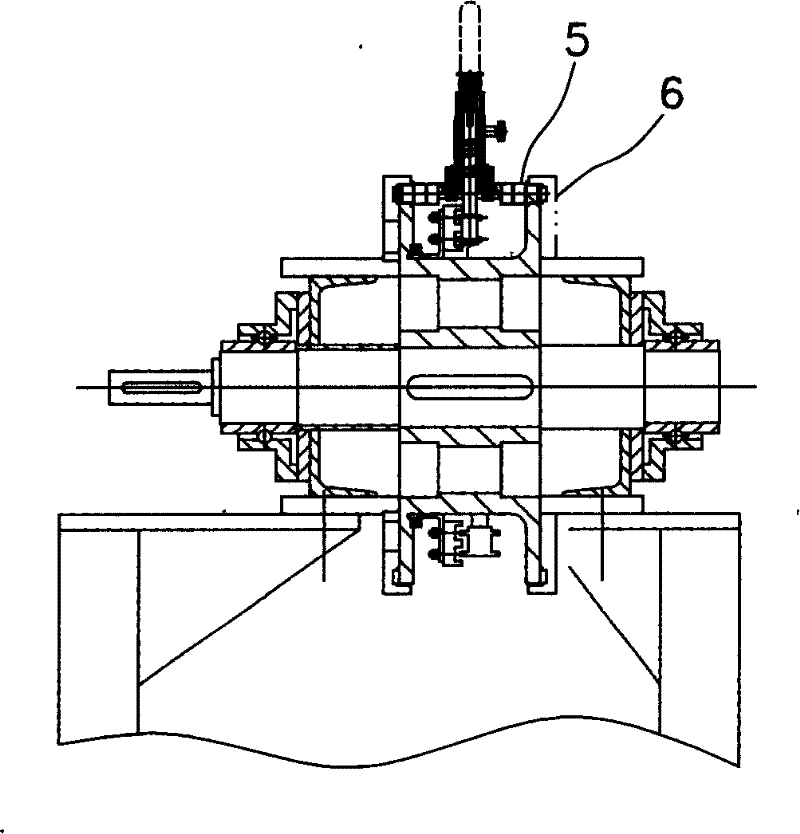

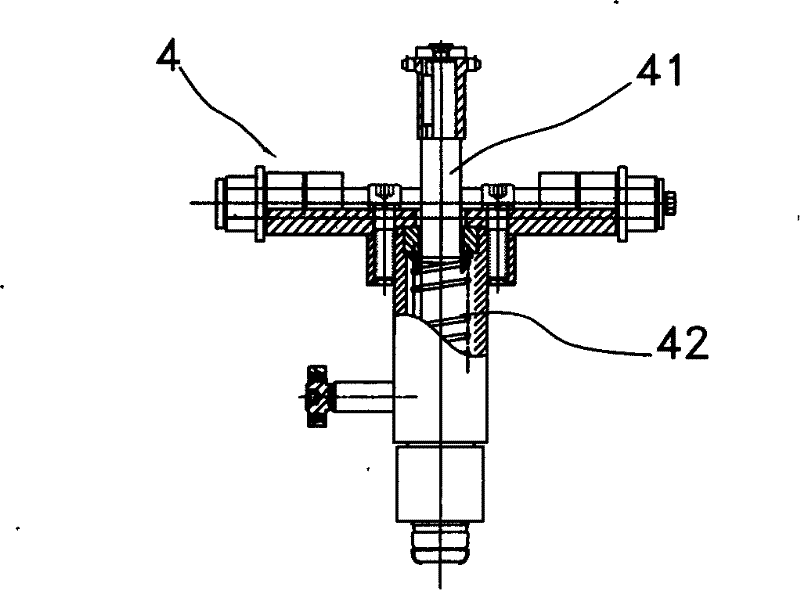

[0022] see Figure 1 to Figure 4 As shown, a chain transmission mechanism of a heating machine includes a main transmission sprocket 1, a tensioning wheel 2 and a chain 3 composed of a plurality of link chains 31, and the chain 3 is installed on the main transmission sprocket 1, tensioned On the wheel 2 and driven by the main transmission sprocket 1, the chain 3 moves, and two heating heads 4 structures are arranged on the side ends of each joint chain 3. The pitch of the joint chain 3 is 2P, and the center distance between the two heating heads 4 installed in the joint chain is P, so the pitch of the joint chain 3 is installed in the joint chain 3 2 times the center distance between two heating heads.

[0023] The link chain 31 includes an inner link plate 311 , an outer link plate 312 parallel to the inner link plate 311 , and a pin shaft 313 for co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com