Multifunctional bottle checker

A bottle inspection machine and multi-functional technology, applied in measuring devices, material analysis by optical means, instruments, etc., can solve the problems of blurred manual inspection standards, slow speed, damage to corporate image, etc., to achieve easy promotion and application, reduce Production cost, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with accompanying drawing:

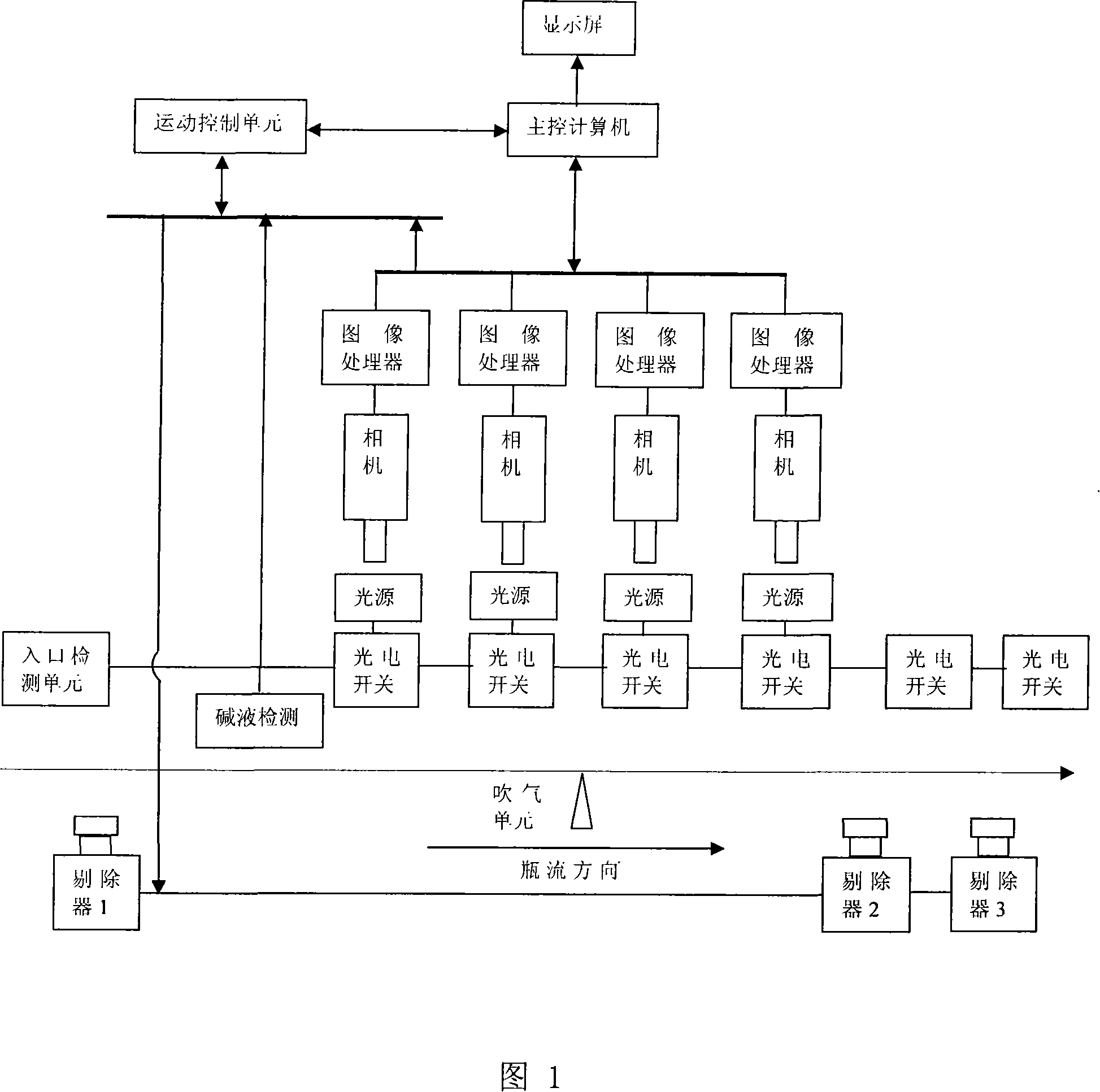

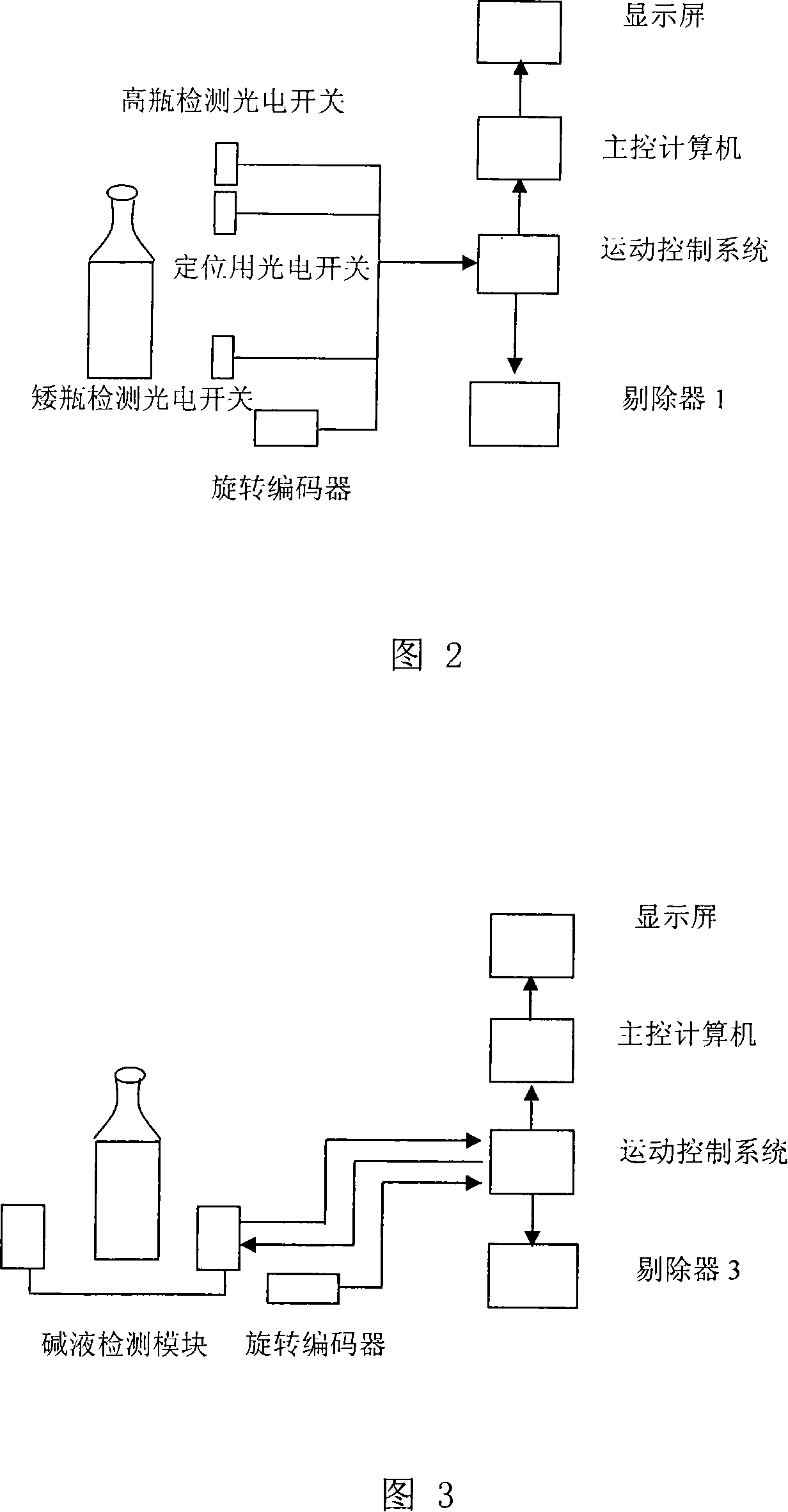

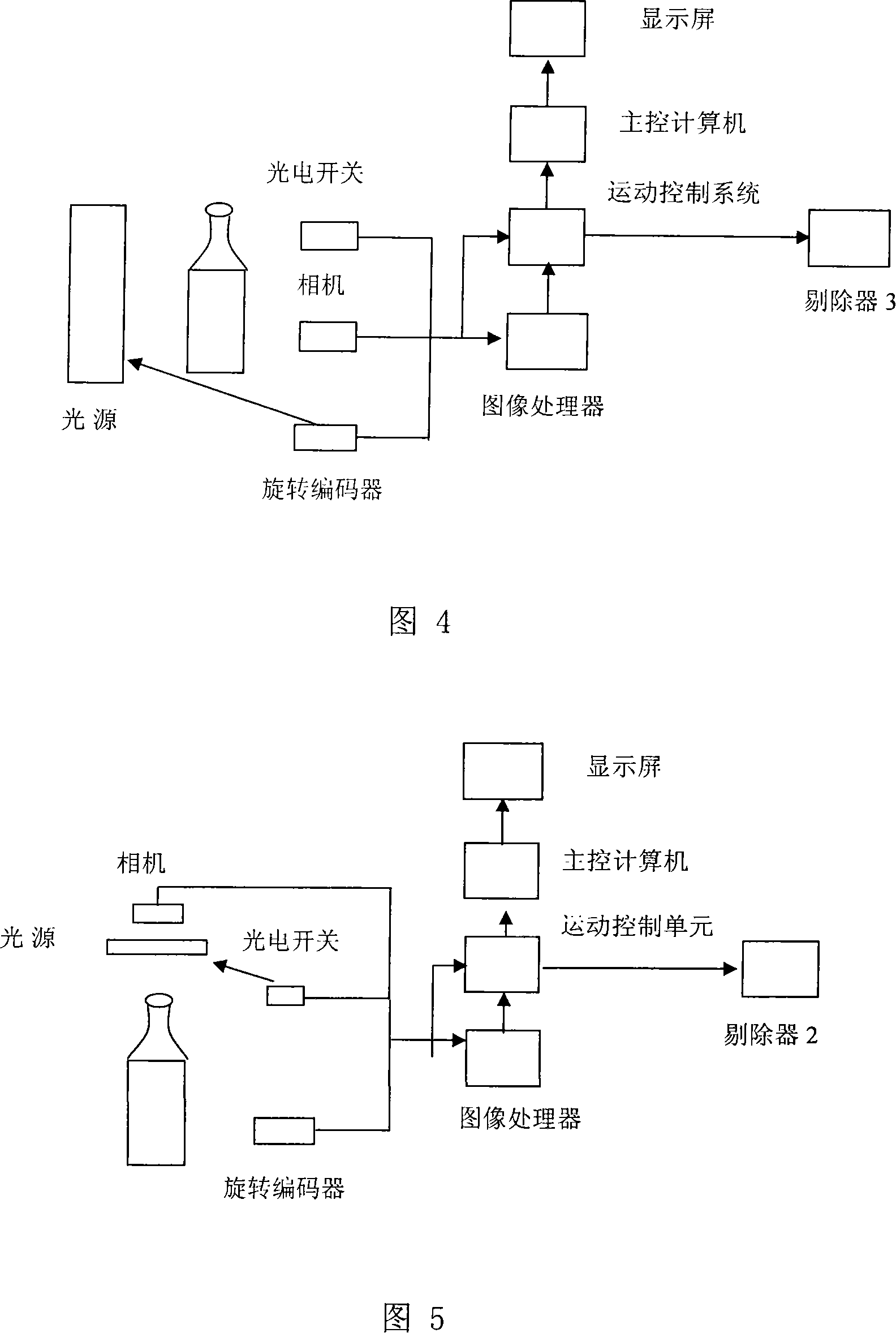

[0025] As shown in Figure 1, the present invention is an all-round multi-vision, multi-sensor information fusion quality detection device, through multiple sensors installed in the production line, a corresponding detection information file is established for the empty bottle entering the detection area, and the transmission mechanism transports The empty bottles to be detected pass through the corresponding detection units in turn, and the data of each detection unit is filled in the detection information file of each bottle. The main control computer judges whether the bottle product is qualified through intelligent processing, discovery and decision-making. The computer issues instructions to the motion control system to classify, sort and reject unqualified products.

[0026] The present invention adopts the concept of modularization to combine, one side is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com