Thick film circuit heating part based on minicrystal glass base plate and its making technology

A glass-ceramic, thick-film circuit technology, applied in electrical components, thick-film resistors, heating element materials, etc., can solve the problems of low cost, high power, and high thermal efficiency, and achieve improved conductivity, energy saving, and insulation performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] As shown in Figure 1 and Figure 2, a thick-film circuit electric heating element based on a glass-ceramic substrate in the present invention includes a substrate and a series of electronic pastes, and the series of electronic pastes are prepared on the substrate in the form of a thick-film circuit. Electronic paste includes packaging paste and electrode paste. The series of electronic pastes are composed of three parts: functional phase, inorganic binder phase and organic carrier. Among them, the substrate is β-quartz solid solution as the main crystal phase Li 2 O-Al 2 o 3 SiO2-P 2 o 3 -La 2 o 3 System glass-ceramic substrate, the nucleating agent is TiO 2 , ZrO 2 .

[0030] Preparation of Li with β-quartz solid solution as the main crystal phase 2 O-Al 2 o 3 SiO2-P 2 o 3 -La 2 o 3 Rare earth thick film circuit heating element of the system glass-ceramic substrate:

[0031] According to the glass-ceramic formula:

[0032] The composition weight ratio o...

Embodiment 2

[0050] The difference between this embodiment and the above-mentioned embodiment is that the substrate is CaO-Al with β-wollastonite as the main crystal phase. 2 o 3 SiO2-B 2 o 3 -La 2 o 3 System glass-ceramic substrate, the composition weight ratio of each oxide is: CaO18~38%, Al 2 o 3 5~26%, SiO 2 30-65%, B 2 o 3 2~16%, La 2 o 3 0.3~15%, Co 2 o 3 0.05~6%, TiO 2 1~10%, ZrO 2 1 to 10%.

[0051] Rare earth resistance slurry performance parameter of the present invention:

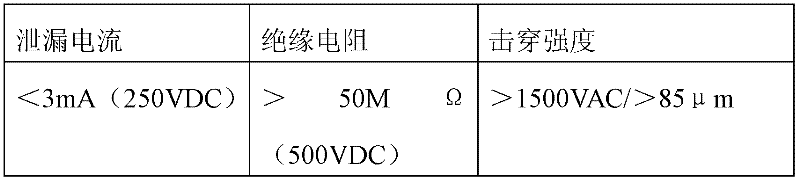

[0052] ①Electrical properties:

[0053] square resistance

resolution

TCR / ppm / ℃

Aging strength

25±2mΩ / □

0.1mm

1000±150ppm×

>10(N / mm2)

10-6 / ℃

[0054] ②Physical properties

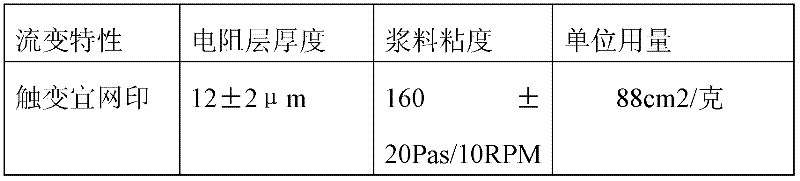

[0055]

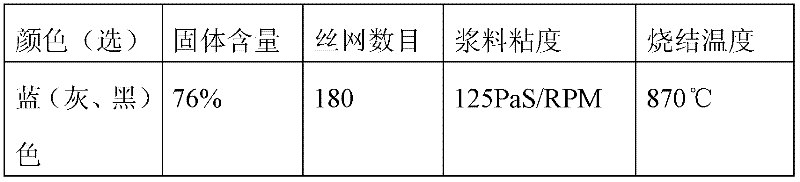

[0056] Rare earth electrode slurry performance parameter of the present invention:

[0057] ①Electrical properties:

[0058] square resistance

resolution

tensile strength

Aging strength

<5±2mΩ / □

0.1mm

>16(N / mm2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com