Fuel cell system

A fuel cell system and fuel cell technology, applied in the direction of fuel cells, fuel cell additives, fuel cell grouping, etc., can solve the problems of large surface area and low thermal efficiency of the shell 1, and achieve reduced heat radiation, uniform temperature, and reduced heat dissipation. radiation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

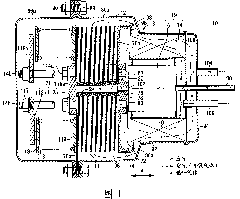

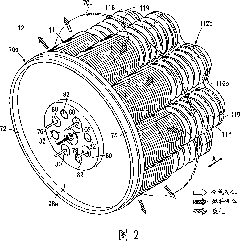

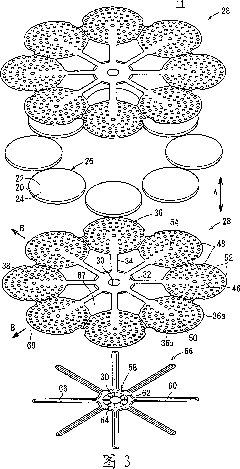

[0036] FIG. 1 is a partial sectional view showing a fuel cell system 10 according to a first embodiment of the present invention. FIG. 2 is a perspective view schematically showing the fuel cell stack 12 of the fuel cell system 10 . The fuel cell stack 12 is formed by stacking a plurality of fuel cells 11 in the direction indicated by arrow A. As shown in FIG.

[0037] The fuel cell system 10 is used in a variety of applications, including stationary and mobile applications. For example, the fuel cell system 10 is mounted on a vehicle. As shown in FIG. 1 , the fuel cell system 10 includes a fuel cell stack 12 , a heat exchanger 14 , a reformer 16 and a housing 18 . Heat exchanger 14 heats the oxygen-containing gas before it is supplied to fuel cell stack 12 . The reformer 16 reforms fuel to produce fuel gas. The fuel cell stack 12 , heat exchanger 14 and reformer 16 are arranged in a housing 18 .

[0038] In the housing 18, a fluid unit 19 comprising at least a heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com