High-frequency heater

A high-frequency heating and equipment technology, applied in microwave heating, electric/magnetic/electromagnetic heating, electric heating devices, etc., can solve problems such as unstable operation, and achieve the effect of reducing high-order harmonic distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

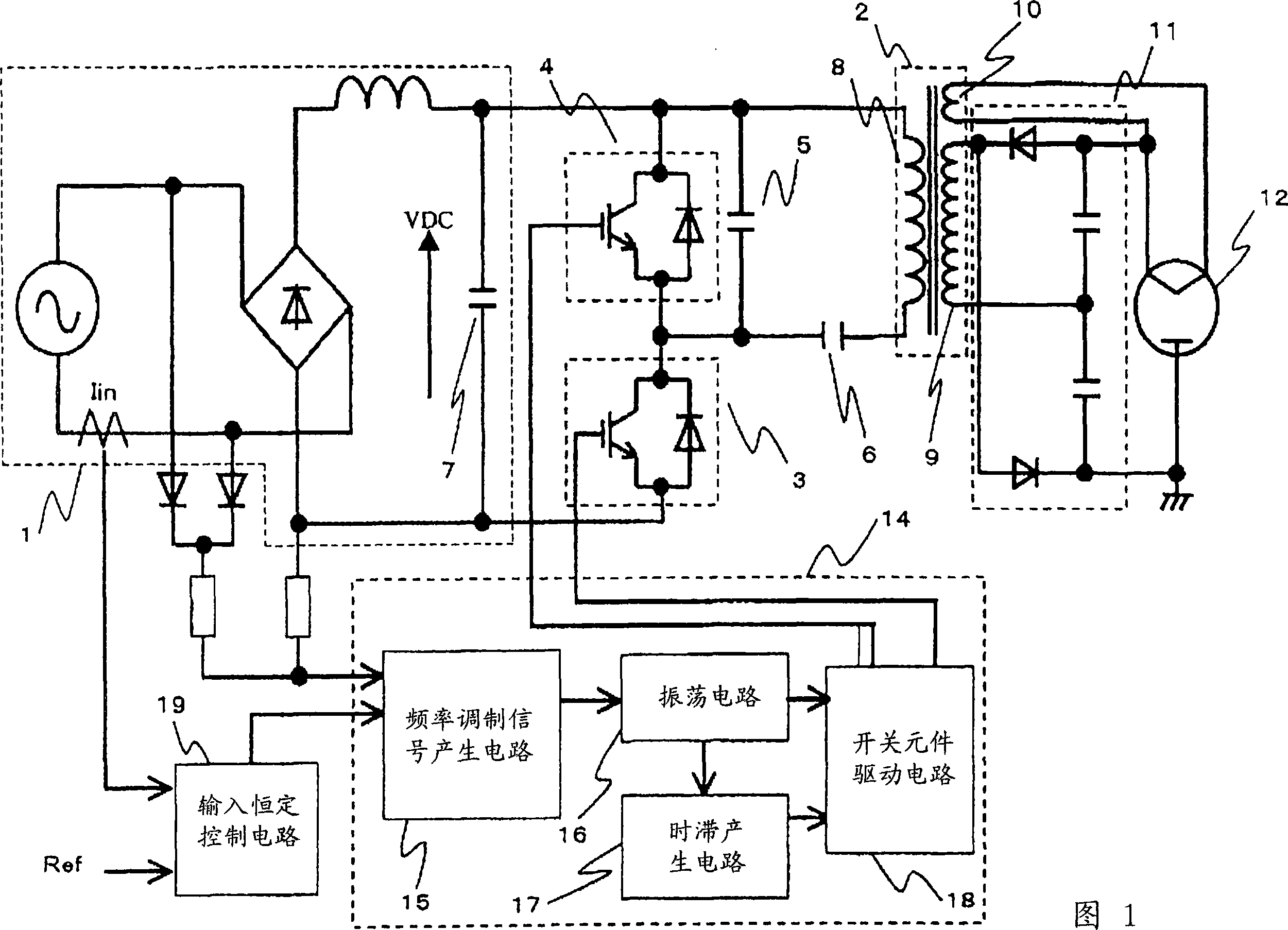

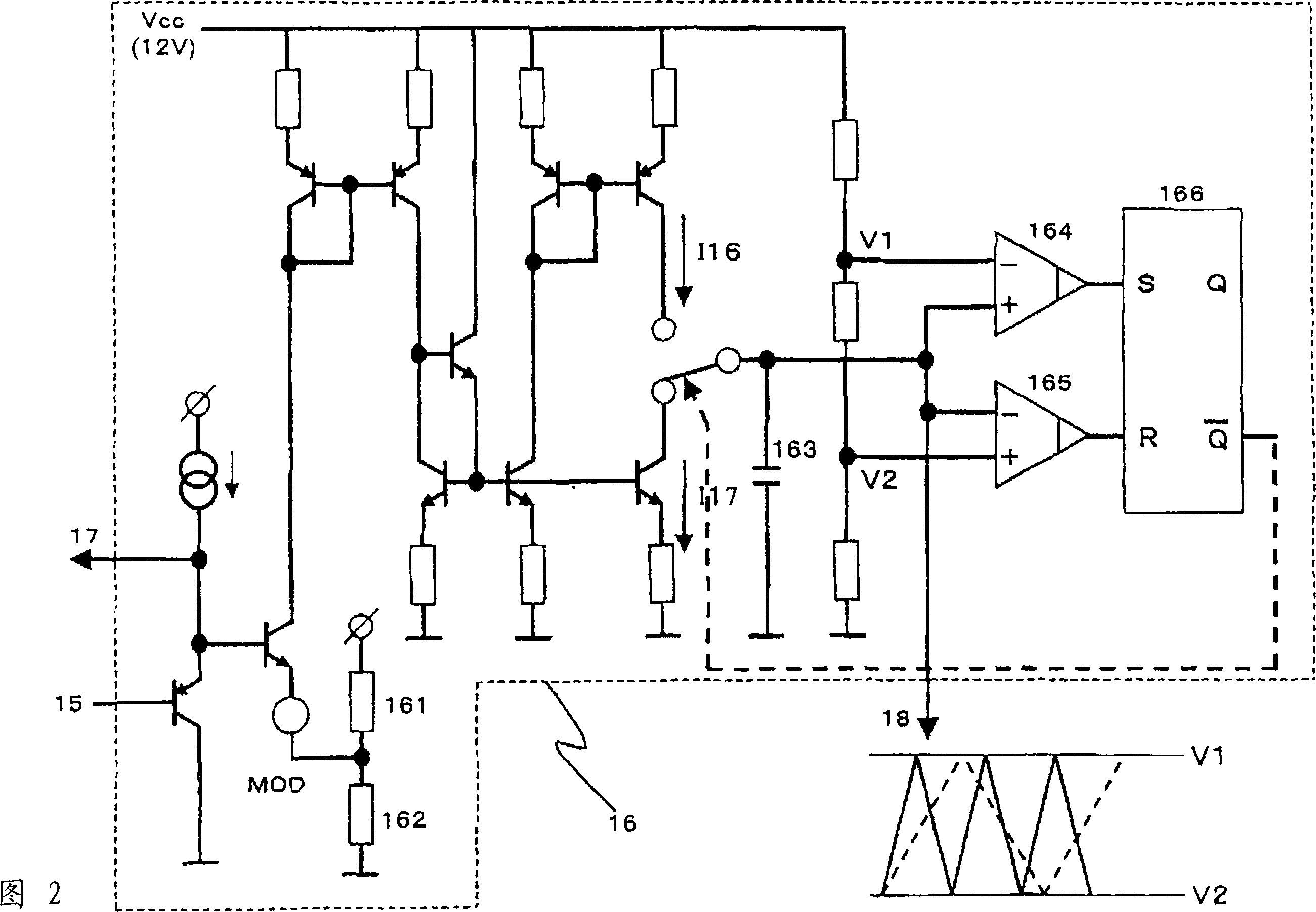

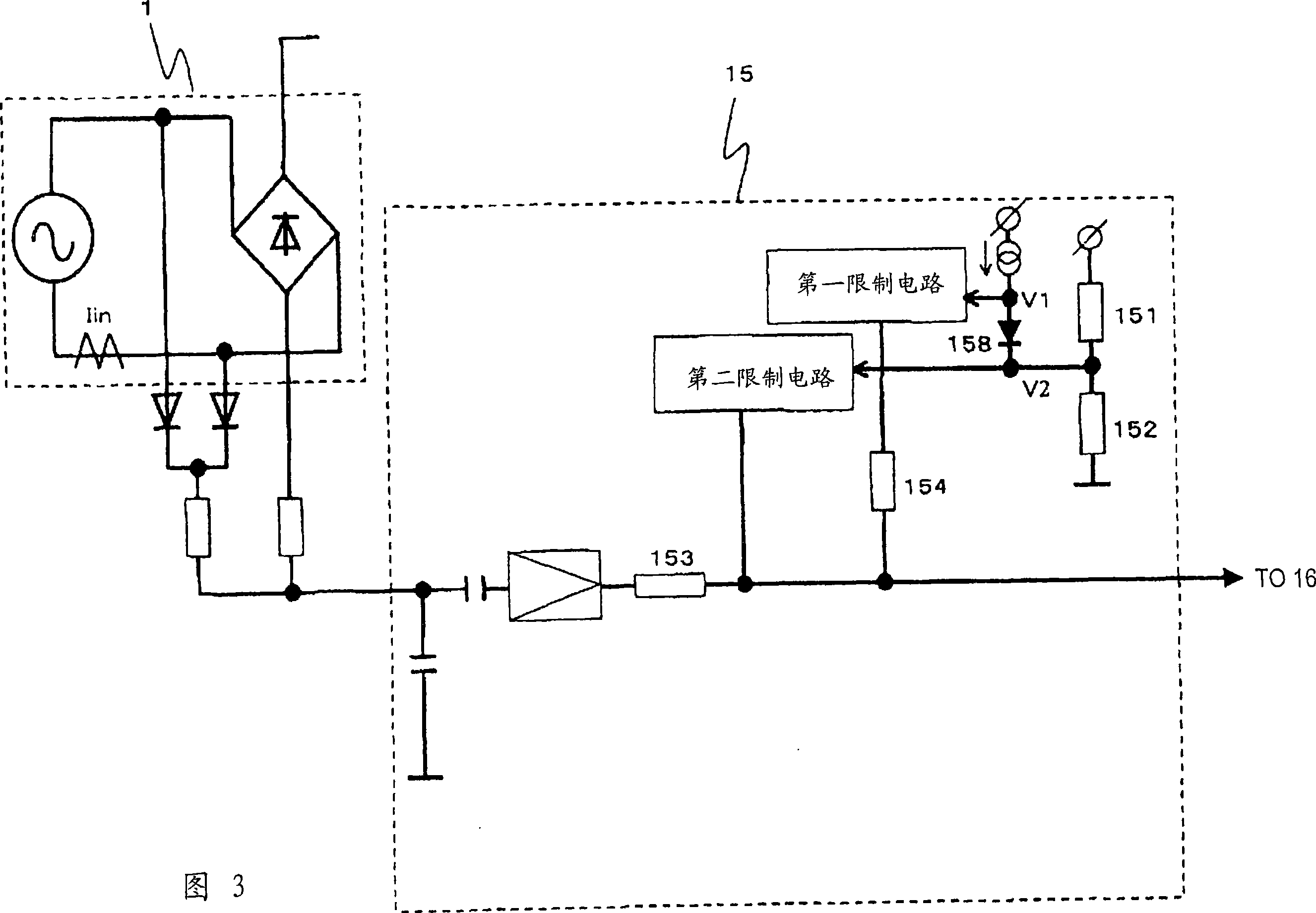

[0077] FIG. 1 shows a circuit diagram of a magnetron drive power supply circuit of a high frequency heating device according to a first embodiment of the present invention. In the inverter circuit, by using the DC power supply 1, the leakage transformer 2, the first semiconductor switching element 3, the first capacitor (snubber capacitor) 5, the second capacitor (resonance capacitor) 6, the third capacitor (smoothing capacitor) 7. The second semiconductor switching element 4, the driving circuit 14, the full-wave power supply double rectification circuit 11 and the magnetron 12 constitute the main circuit. Since the arrangements of the above-described main circuits other than the drive circuit 14 are the same as those of FIG. 11 , explanations thereof are omitted.

[0078] In the drive circuit 14 for driving the first and second semiconductor switching elements 3 and 4, first, a frequency modulation waveform is formed by the frequency modulation signal generation circuit 15 b...

Embodiment 2

[0088] FIG. 5 indicates a frequency modulation signal generating circuit employed in a magnetron-driven inverter circuit of a second embodiment of the present invention, which is different from the first embodiment described above in that a resistor 155 is newly provided. According to this embodiment, the second limiting function can be realized by limiting the variation of the frequency modulation waveform by gradually increasing the sensitivity due to the separation of the frequency from V2 in lower than or equal to the fixed voltage V2 (claim 5).

[0089] Fig. 6 shows frequency modulation waveforms of the second embodiment. Similar to the first embodiment, the waveform change around the lowest frequency becomes smooth, so that sudden changes in frequency can be suppressed.

Embodiment 3

[0091] FIG. 7 indicates a frequency modulation signal generating circuit employed in a third embodiment of the present invention, which is different from the first embodiment described above in that a transistor 159 is provided in the first limiting circuit.

[0092] According to this third embodiment, the change in the resistance value of the PN junction indicated by the voltage versus current characteristic is adopted by the resistor 159 as a first limiting function (claim 6).

[0093] When the potential difference of the PN junction increases, the resistance value of the PN junction decreases. As a result, since the potential of the divided waveform obtained by rectifying the commercial power supply voltage becomes lower than the voltage V1 and separated from this voltage B1, the sensitivity of the first limiting function rises so that the waveform lower than or equal to V1 is smoothly changed .

[0094] In addition, although a plurality of sets of first restriction functi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com