Acoustic device and electronic apparatus

A technology for acoustic devices and electronic equipment, applied in the field of acoustic devices and electronic equipment, can solve the problems of negative effect on the sensitivity of the acoustic system, affect the service life of the speaker unit, and damage the acoustic performance of the speaker unit, so as to improve the sensitivity of the low frequency band and the sensitivity of the low frequency , the effect of reducing the resonance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

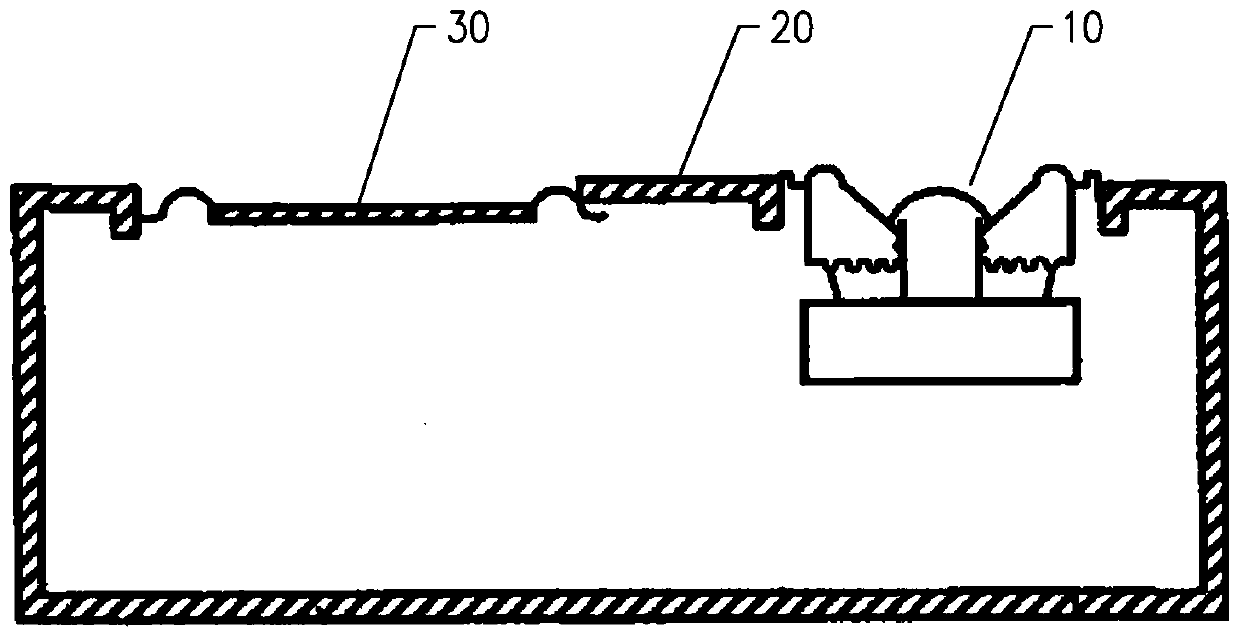

[0045] Such as Figure 3A As shown, an acoustic device includes a sounding unit 1, wherein, in this embodiment, the sounding unit 1 is a miniature sounding unit, more specifically, the sounding unit 1 is a miniature moving coil speaker. The sound unit 1 generally includes a housing and a vibration system and a magnetic circuit system fixed in the housing. The vibration system includes a vibrating diaphragm 11 fixed on the housing and a voice coil combined with the vibrating diaphragm 11. The magnetic circuit system is formed with The magnetic gap, the voice coil is set in the magnetic gap, and the voice coil reciprocates up and down in the magnetic field after being fed with alternating current, thereby driving the vibrating diaphragm 11 to vibrate and produce sound.

[0046] The acoustic device is provided with a sound outlet 4, and the sound waves on the front side of the vibrating membrane 11 are radiated to the outside through the sound outlet 4, and the sound waves on the...

Embodiment 2

[0077] The main difference between this embodiment and the above-mentioned embodiments is that in this embodiment, a plurality of sounding units 1 and first airtight chambers 21 are provided in one-to-one correspondence, and a second airtight chamber 31 is provided, and each of the first airtight chambers Each cavity wall of the cavity 21 is provided with a flexible deformation part. Specifically, such as Figure 7 As shown, the acoustic device in this embodiment includes two sounding units 1, and two first airtight cavities 21 are correspondingly designed at the same time, the second airtight chamber 31 is one, and the cavity walls of the two first airtight cavities 21 Flexible deformation portions 22 are respectively designed. This design can facilitate the application in the case of an acoustic device or system that requires multiple sounding units 1 , such as stereophonic or array design requirements. The number of first airtight chambers in this embodiment may also be o...

Embodiment 3

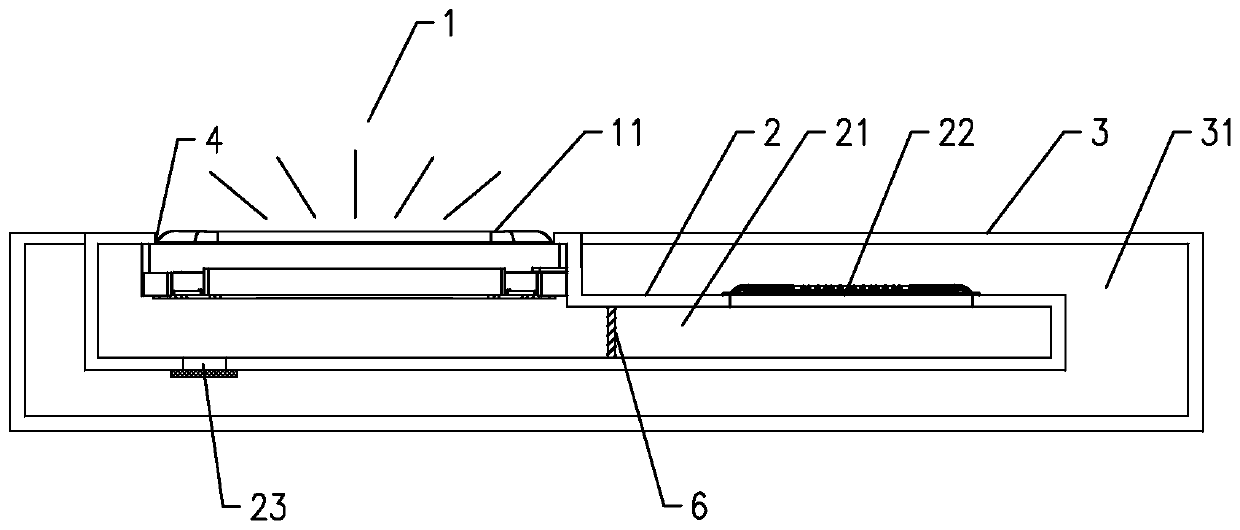

[0079] This embodiment discloses an electronic device 5, such as Figure 8 with Figure 9 As shown, the acoustic device in the above-mentioned embodiments is installed on the electronic device 5, which may be a mobile phone, a tablet computer, a notebook, and the like.

[0080] The electronic device 5 specifically includes a casing of the electronic device, and at least a part of the casing of the electronic device is used to form the first airtight cavity 21 and / or the second airtight cavity 31 of the acoustic device. That is, part or all of the cavity wall of the first closed cavity 21 is formed by the casing of the electronic device, or part or all of the cavity wall of the second closed cavity 31 is formed by the casing of the electronic device, or, Part or all of the cavity walls of the first sealed cavity 21 and the second sealed cavity 31 are formed by the casing of the electronic device. In the present invention, the casing of the electronic device doubles as the cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com