Energy conversion device for engine vent gas

An energy conversion device and engine technology, applied in exhaust devices, engine components, combustion engines, etc., can solve the problems of high harmful substances, waste of exhaust energy, and insufficient utilization of exhaust energy, so as to improve combustion integrity, The effect of increasing the degree of combustion expansion and increasing the value of lean burn area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

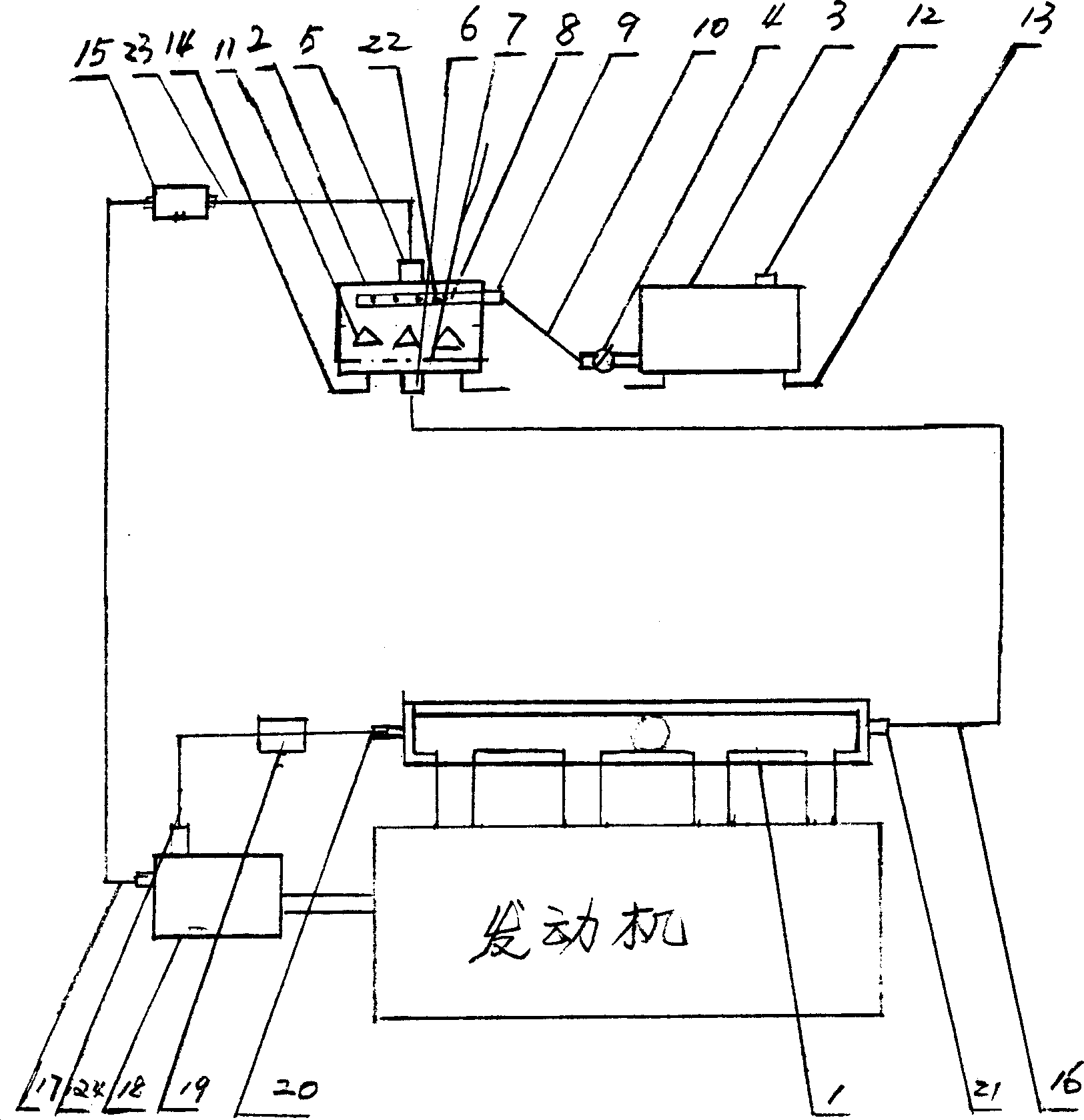

[0017] The present invention consists of a lower-end cavity exhaust pipe (bronchial junction) as an interlayer high-temperature purification chamber 1 connected with a conduit 6 to a reaction tank 2, a liquid storage tank 3 with a flow control valve 4 and a sedimentation box 15.

[0018] The interlayer high-temperature purification chamber 1 formed by the exhaust pipe of the present invention is provided with an outlet 20 at one end, and the outlet 20 is connected with the air filter 18, and the other end is provided with an inlet 21, and the inlet 21 is connected with the outlet 6 of the reaction tank 2 with a metal conduit. The reaction tank is provided with a carrier 11 on a filter screen 7 . The upper part is provided with an infusion tube 8, the side is provided with micropores 22, the top is provided with an air outlet 5, one end is blocked, the other end is connected to the inlet 9, the bottom is provided with a bracket 14, and the reaction tank inlet 9 and the liquid st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com