MEMS gyroscope accurate installation reference component and installation method thereof

A technology of installation reference and gyroscope, which is applied to gyroscope/steering sensing equipment, gyro effect for speed measurement, instrument and other directions, can solve the problems of poor anti-interference ability, difficult to control precision, poor stability, etc., to improve installation accuracy, Improved installation accuracy and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

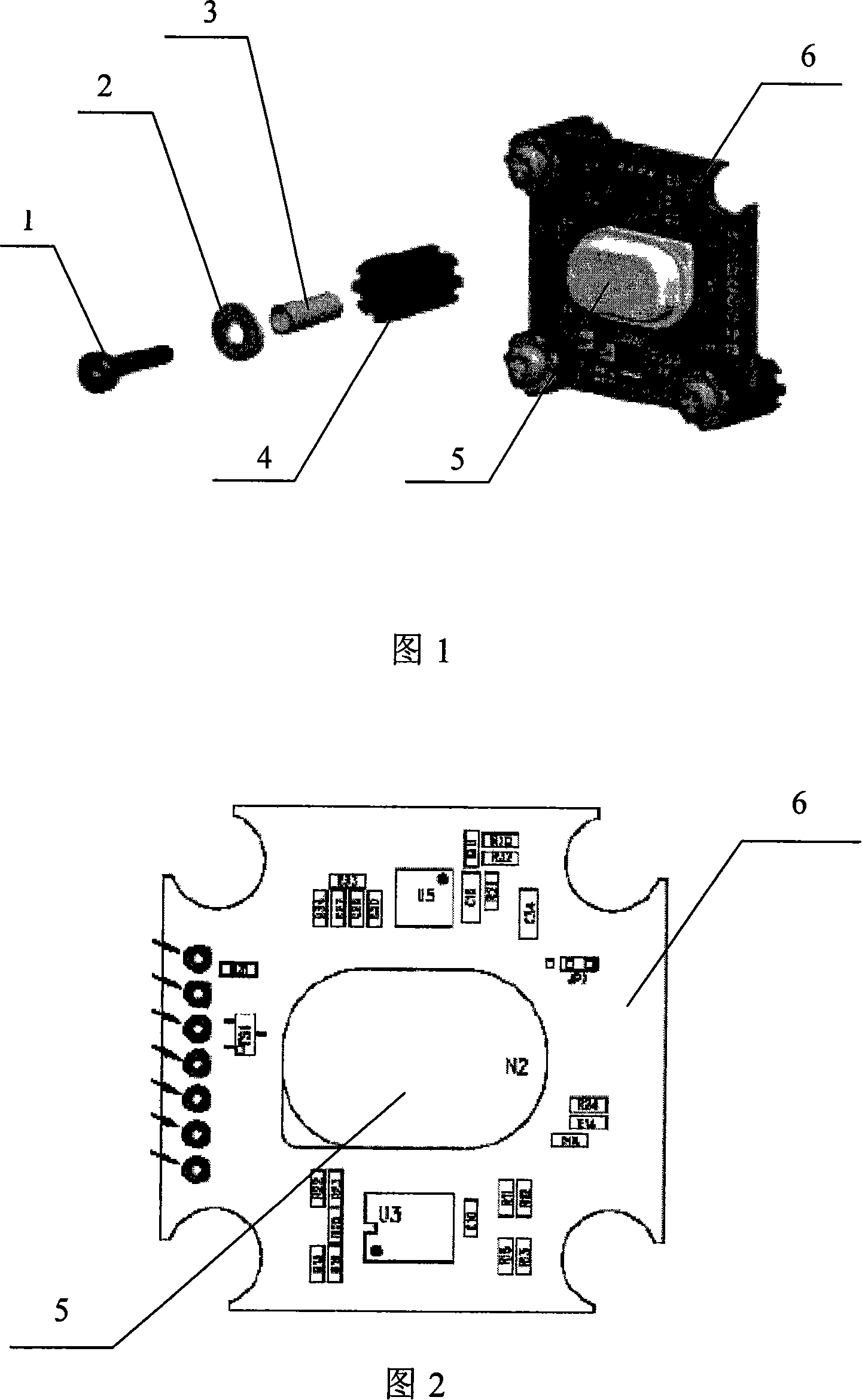

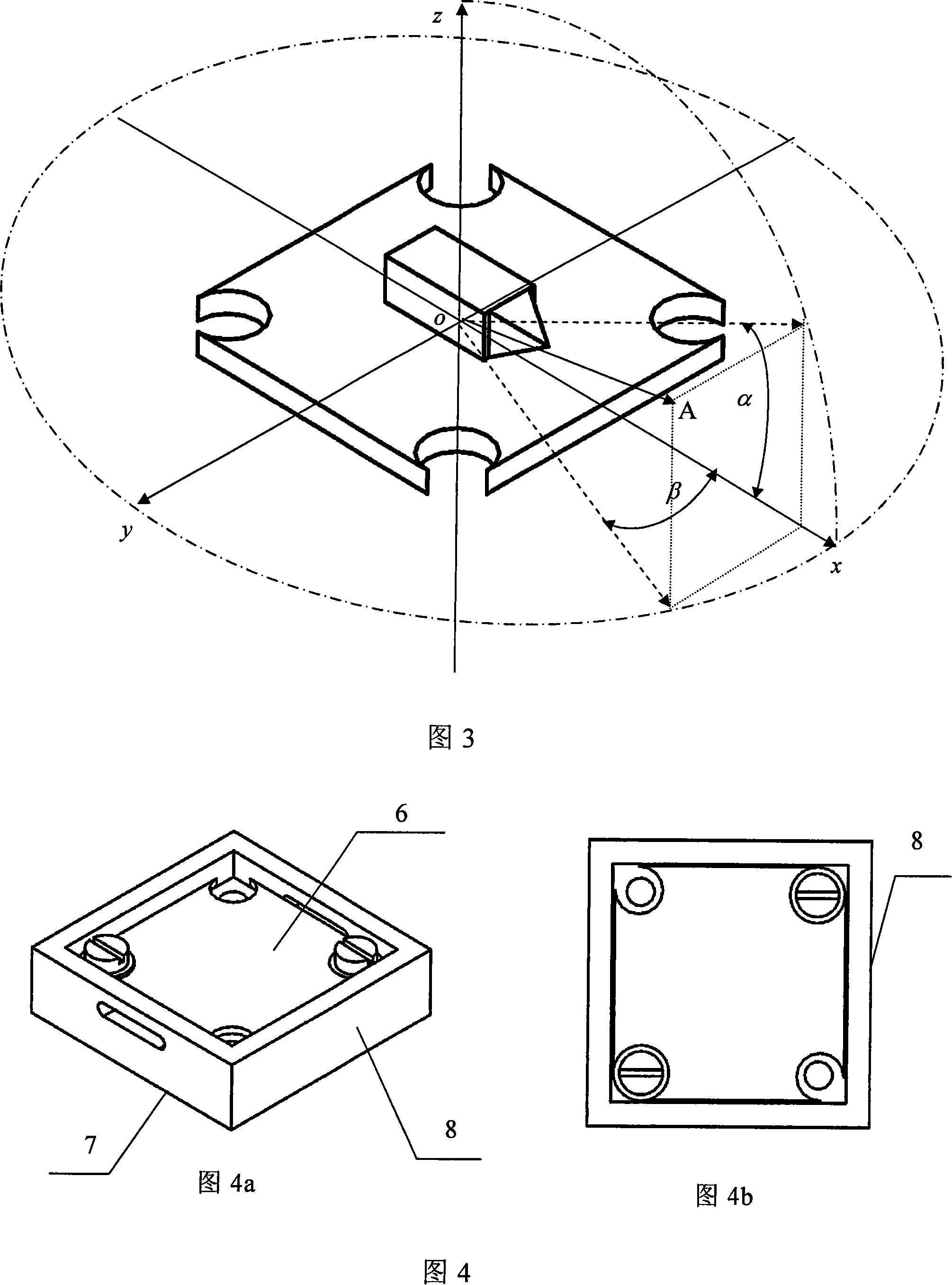

[0033] The present invention takes the micro-MEMS gyroscope and the quartz MEMS gyroscope LCG50 produced by BEI Company as an example, and designs a precision-installed reference body assembly.

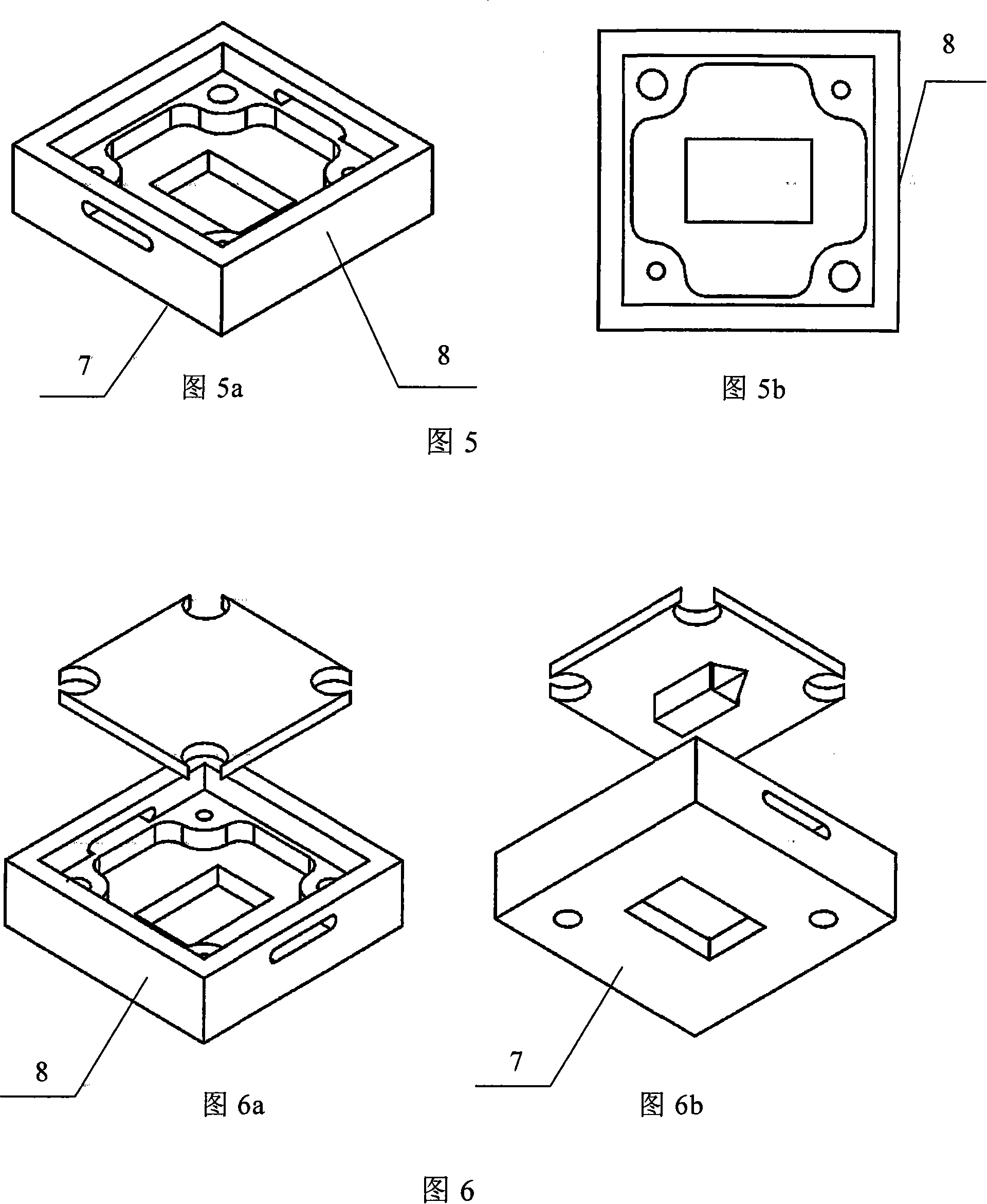

[0034] The assembly diagram of the precise installation reference body assembly of LCG50 is shown in Figure 4, including the precision installation reference body and the micro MEMS vibrating gyroscope body at the level of the sensitive axis. Its precision installation datum body is shown in Figure 5, the main body is a cuboid with a smooth outer surface, including a first datum plane, a second datum plane and an inner concave space. The inner recessed space is recessed from the upper surface to the inside, and the shape is designed according to the external dimensions of the LCG50 gyroscope body, so that the LCG50 gyroscope body is embedded in the inner recessed space of the precision installation reference body, and the LCG50 gyroscope body and the precision installation reference bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com