Spraying degasser

A degassing device, degassing container technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as poor reproducibility, excessive water vapor, manual operation, etc., achieve accurate and reliable measurement methods, simple design and operation, and solve Effects of moisture problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

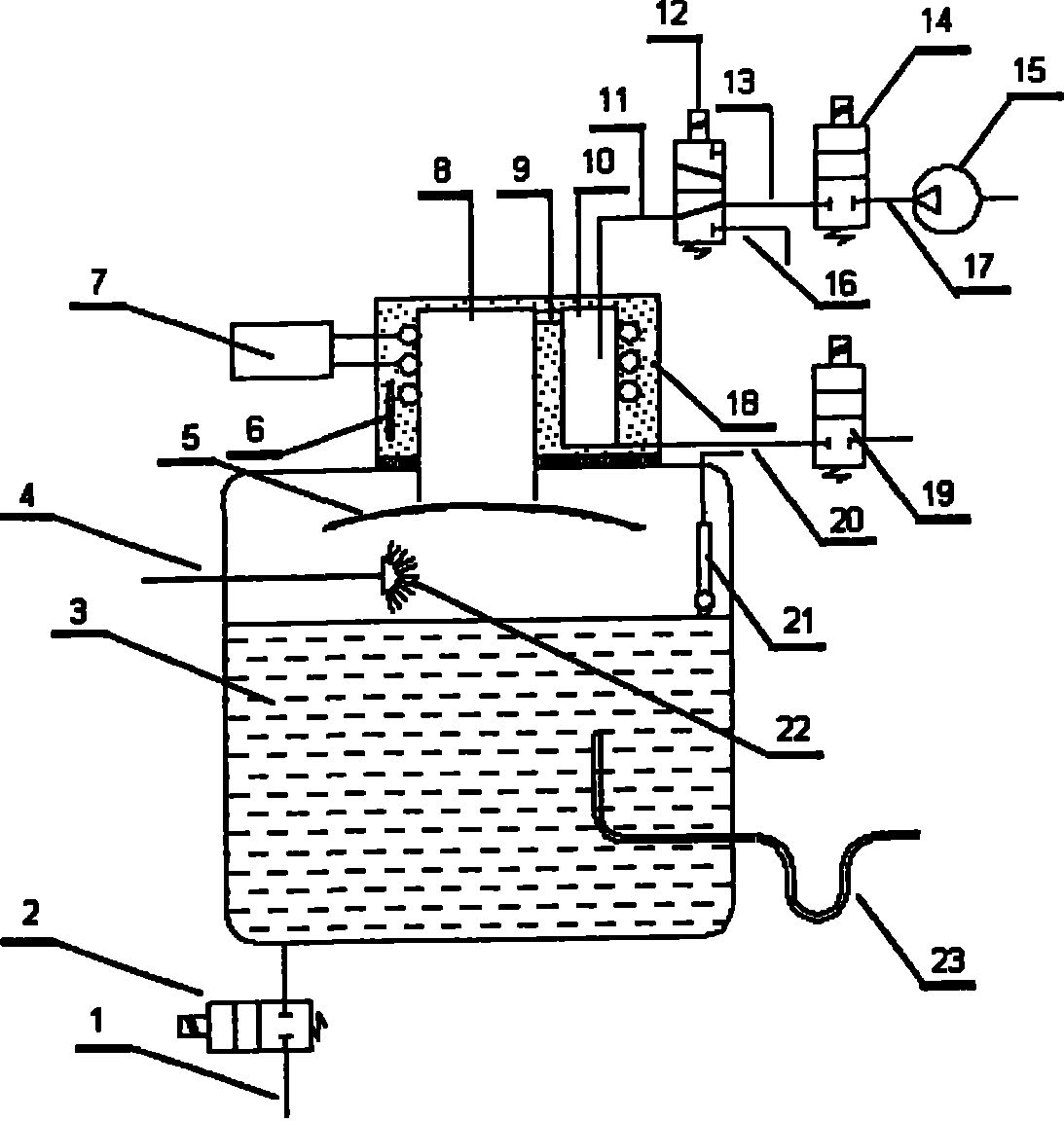

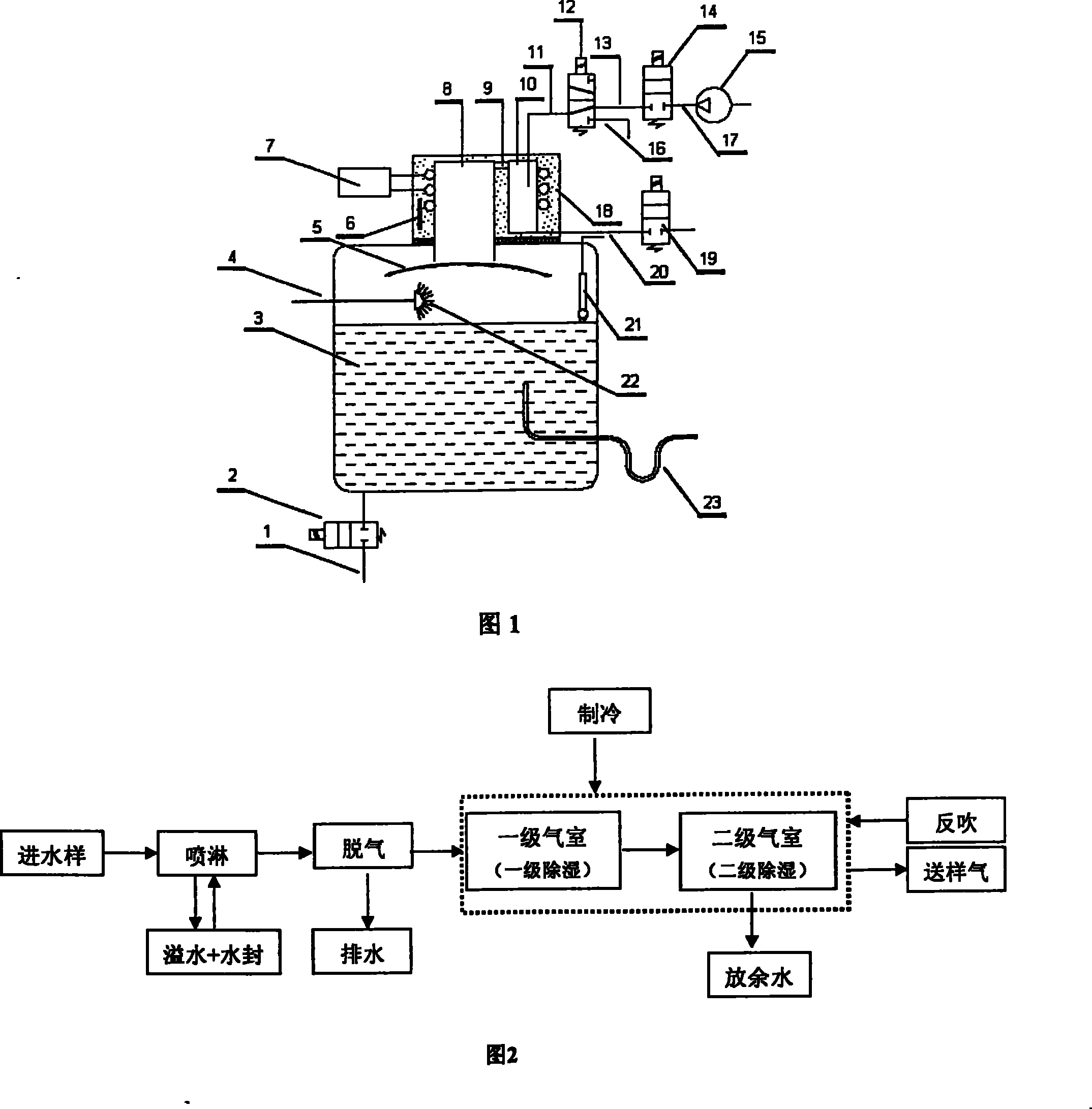

[0021] As shown in Figure 1, it is a schematic structural view of a spray degassing device, said a kind of spraying degassing device consists of a drain pipe 1, a solenoid valve A 2, a degassing container 3, an inlet pipe 4, a baffle plate 5, Temperature control system 6, refrigeration system 7, primary air chamber 8, connecting pipe A 9, secondary air chamber 10, connecting pipe B 11, two-position three-way solenoid valve A 12, connecting pipe C 13, solenoid valve B 14, Reverse blowing pump 15, air pipe 16, connecting pipe D 17, intercooled low-temperature metal test bath 18, two-position three-way solenoid valve B 19, residual water pipe 20, liquid level sensor 21, nozzle 22, and overflow pipe 23.

[0022] The drain pipe 1 is installed at the bottom of the degassing container 3 through the solenoid valve A2, and the overflow pipe 23 is installed on one side of the lower end of the degassing container 3. The outlet of the overflow pipe 23 is U-shaped, and its inner diameter is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com