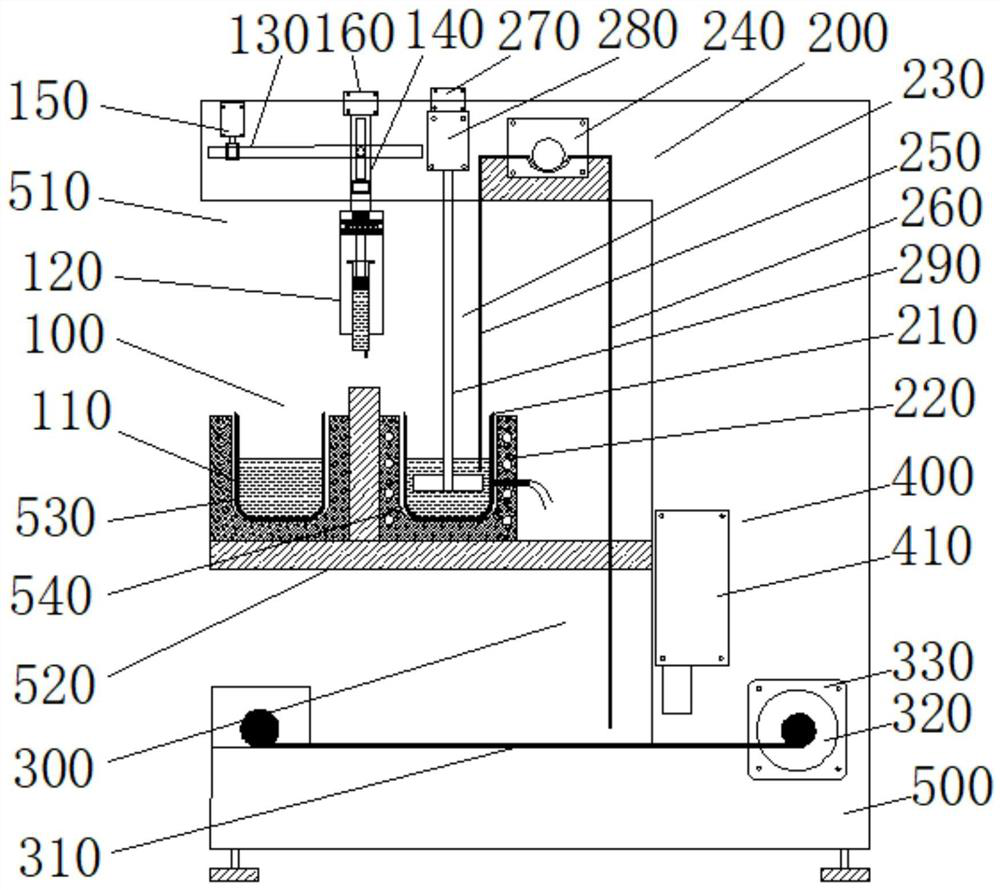

Bentonite montmorillonite content automatic detection equipment and method

A technology of automatic detection and bentonite, which is applied in the direction of chemical analysis by titration, analysis by causing chemical reaction of materials, and material analysis by observing the influence of chemical indicators, etc. It can solve the problems of cumbersome titration process and achieve Quick detection, reduction of human error, automatic continuous detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

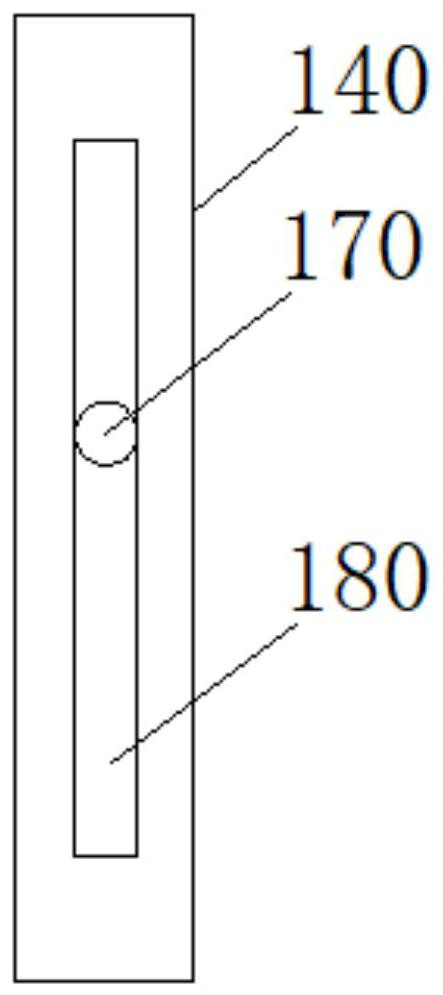

Method used

Image

Examples

Embodiment 1

[0045] Example 1. In this example, sodium bentonite for pellets produced by a bentonite enterprise in Jiangsu Province is used as raw material. The main valuable component in the ore is montmorillonite, and the content of montmorillonite is between 40% and 46%. The proportion of 200 mesh is greater than 99%.

[0046] The application steps of a kind of bentonite montmorillonite content automatic detection equipment and detection method provided by the application are as follows:

[0047] 1. Prepare 100ml of 0.2% methylene blue solution in advance, pour it into the titration container 110, and set it aside;

[0048] 2. Randomly weigh 20g of bentonite, place it in a medium oven and dry it at 115°C until the weight is constant;

[0049] 3. Weigh 0.2 g of dried bentonite with an analytical balance (precision 0.0001 g), add the weighed bentonite and 50 mL of distilled water into the container 210 to be titrated, and then add 20 mL of sodium pyrophosphate solution;

[0050] 4. Use ...

Embodiment 2

[0060] Example 2, the application steps of this example are basically the same as those in Example 1, except that the bentonite used for testing is a certain brand of bentonite from Jiangsu, the content of montmorillonite is known to be 61%, and the proportion of -200 mesh is greater than 99%. Each sample was tested 3 times, and the test results are shown in Table 2.

[0061]

[0062] Two kinds of titration methods contrast in table 2 embodiment 2

[0063] As can be seen from the data in Table 2, compared with the standard value, the final titration results of the two methods are acceptable. Similarly, the single fluctuation of the present application is smaller and the time is shorter, while the single error of manual titration is larger, longer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com