Formworkfor elevator well of high rising building and construction method thereof

A technology for high-rise buildings and construction methods, which is applied in construction, building structure, formwork/formwork/work frame, etc., can solve the problems of multiple man-hours, complicated production, and it is not easy to adjust to the vertical angle, and achieves reduced labor and operation. Simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

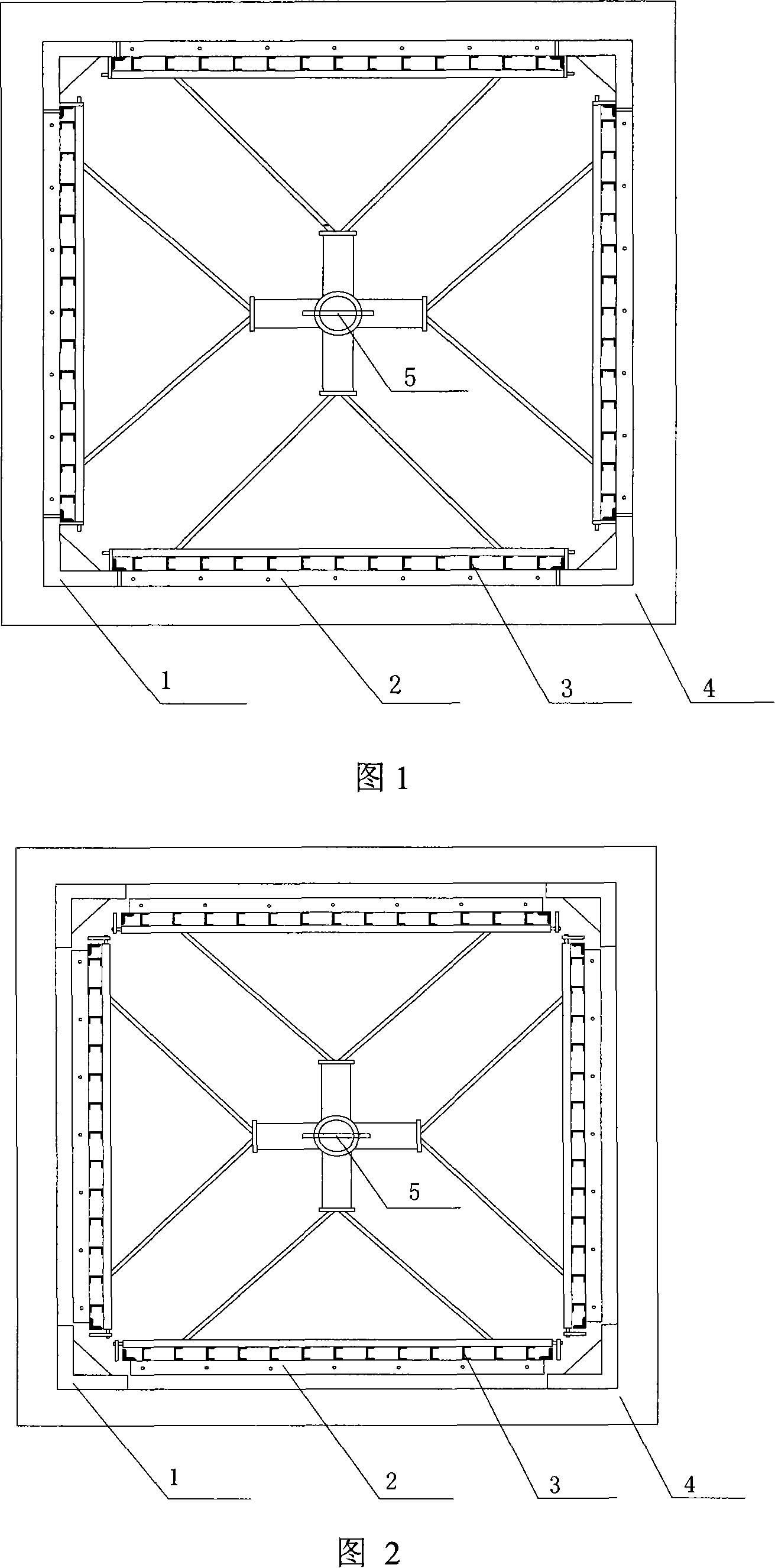

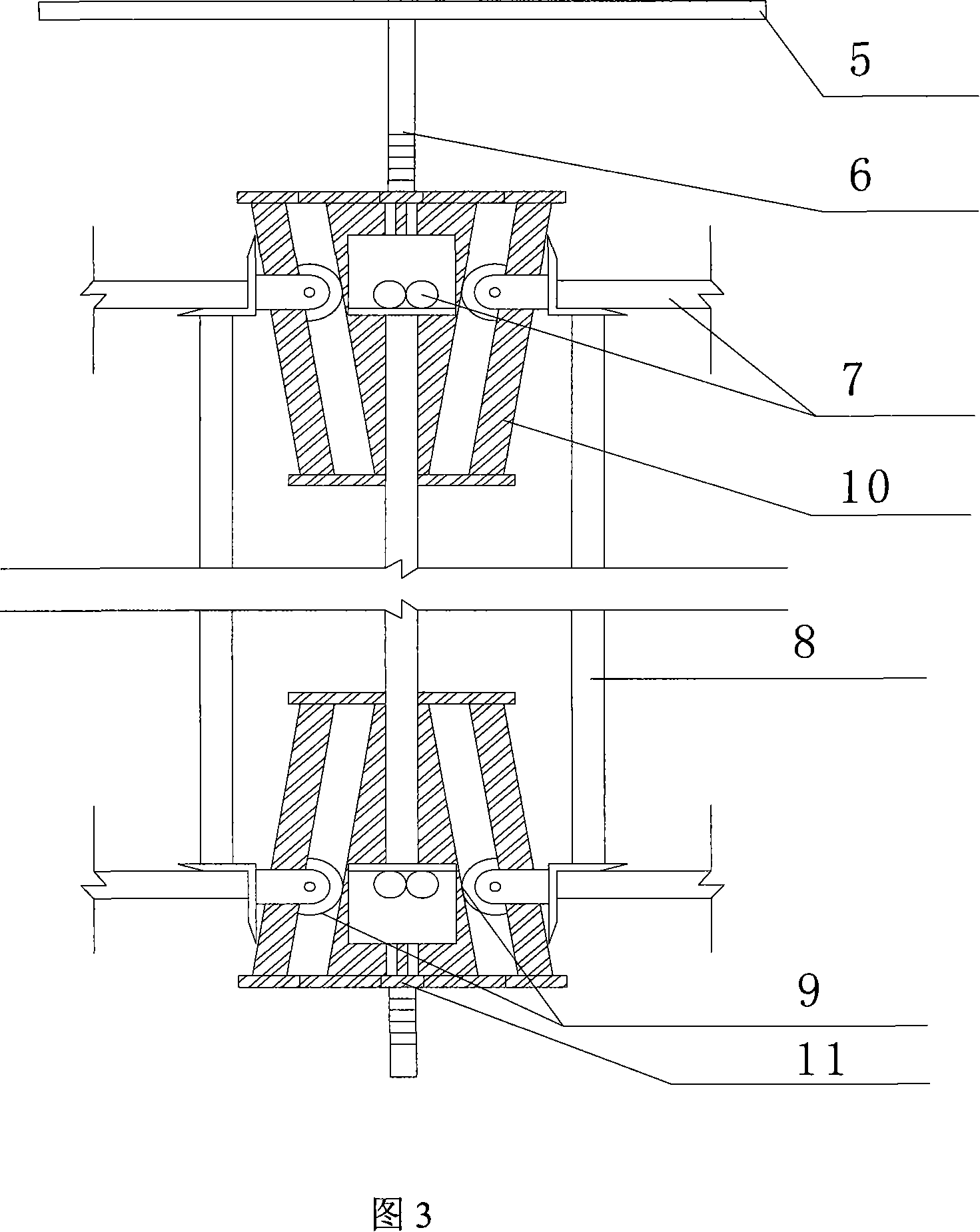

[0020] 实施例见图1-3。 The high-rise building elevator shaft mold in the specific embodiment comprises four corner formworks 1 and four large formworks 2, and the large formwork 2 is supported and supported by a total of sixteen steel braces 7 in two up and down lines, and the upper steel braces meet in a pair The upper control block 10 that controls the expansion and contraction of the upper steel brace, and the lower steel brace meet at a lower control block 11 that controls the expansion and contraction of the lower steel brace; there are tracks on the upper control block 10 and the lower control block 11, and there is a track between the track and the side wall. A hole for the steel brace to pass through; the steel brace 7 in the same vertical plane up and down is rigidly connected by the fixed column 8; a pulley is arranged between the steel brace 7 and the track, and the track of the upper control block 10 is inclined outward from the upper part; The block 11 is inclined downw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com