Method and system for improving fuel economy and environmental impact operating a 2-stroke engine

An environmental impact, engine technology, applied in the direction of engine lubrication, engine components, machines/engines, etc., can solve the problem of no two-stroke diesel engine, etc., and achieve the effect of reduced maintenance frequency, reduced emissions, and reduced friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

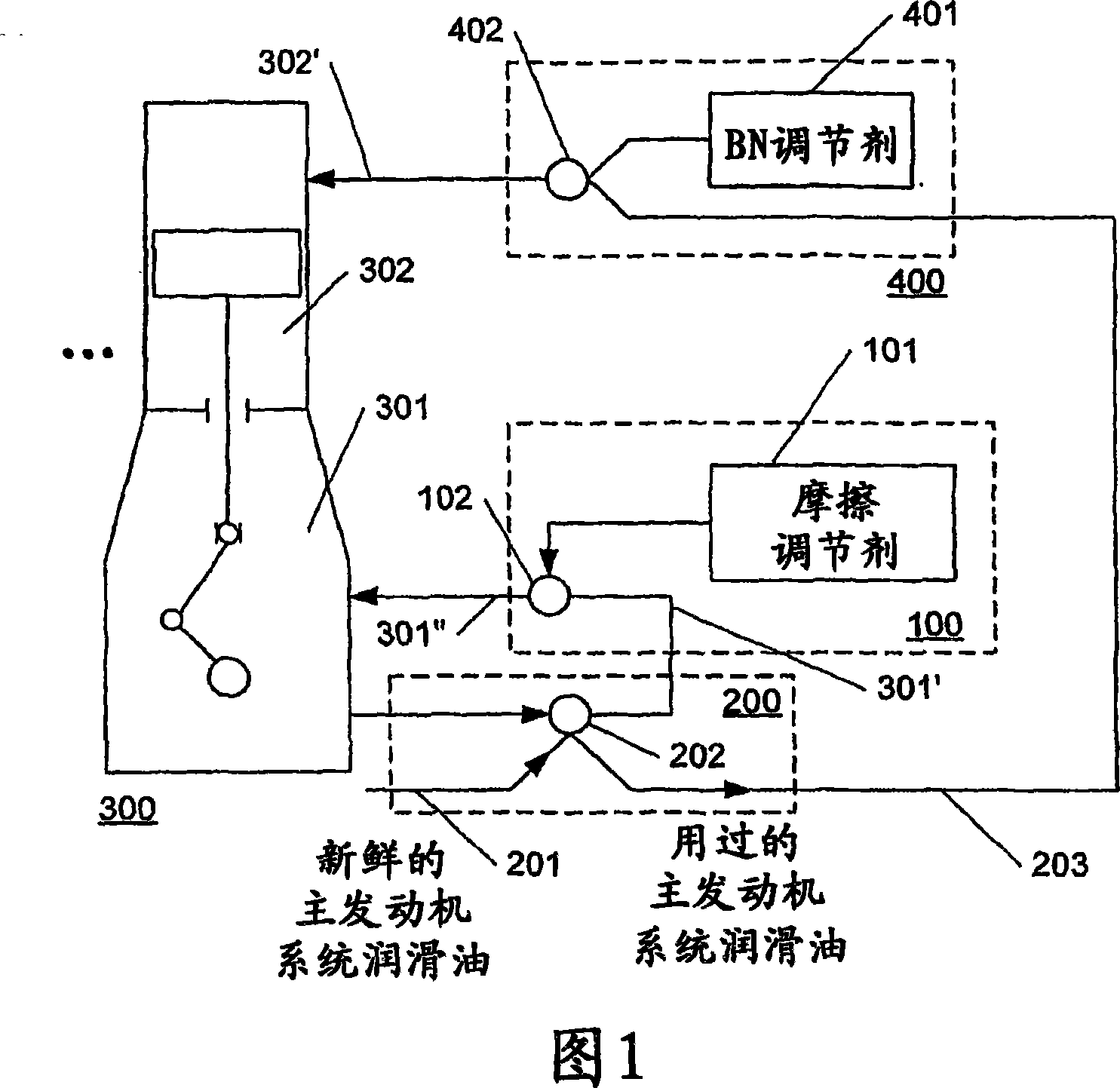

[0054] Figure 1 shows a schematic flow diagram of one embodiment of the present invention. Shown is a schematic representation of at least one two-stroke crosshead diesel engine (300). The engine comprises a lubricating system comprising a so-called system oil (301), which is generally used for lubricating and cooling engine bearings and eg oil-cooled pistons and for actuation and / or control of various valves or the like. Another lubrication system includes a total loss lubricant or cylinder oil (302), which is typically used to lubricate the engine's cylinders, piston rings and piston skirts.

[0055] Except as explained below, the engine (300) corresponds to a known prior art two-stroke engine.

[0056] In accordance with the present invention, also described is a friction modulation method / system (100) for reducing fuel consumption in a two-stroke engine. The friction adjustment method / system (100) obtains system lubricating oil (301') from at least one engine (300), wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com