Furnace drying method for the strip steel surface coating

A surface coating and strip steel technology, which is applied to the surface coating liquid device, coating, pretreatment surface, etc., can solve the problems of strip temperature rise, unfavorable cooling of finished strip steel, coating cracks, etc. , to achieve the effect of reducing the heating temperature, facilitating cooling and uniform temperature change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

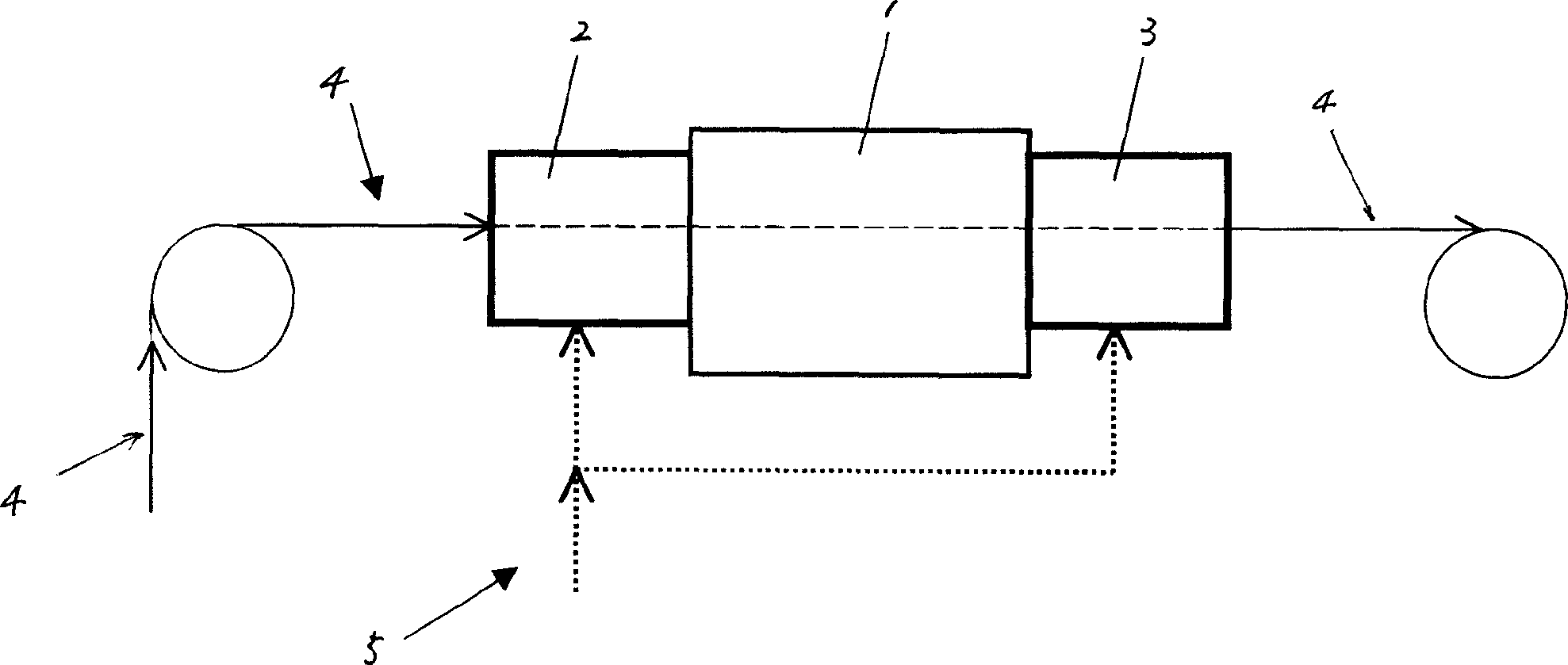

[0009] As shown in the figure, use electricity, gas or steam to heat the purified air through a heat exchanger, and send the obtained hot air 5 into the inlet air box 2 and the outlet air box 3 of the electromagnetic induction heating furnace 1 respectively. When the layer strip steel 4 passes through the inlet bellows 2, the electromagnetic induction heating furnace 1 and the outlet bellows 3 continuously, the pre-drying of the coating surface is realized in the inlet bellows 2, and the strip steel is heated in the electromagnetic induction heating furnace 1 to realize internal drying. The final drying is realized after exiting the air box 3; the temperature of the hot air is controlled within the range of 120°C to 200°C by adjusting the heating amount of the heat exchanger by electricity, gas or steam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com