Production technology of FRP roller, the production equipment and FRP roller thereof

A production process and production equipment technology, applied in the direction of shafts, bearings, coatings, etc., can solve the problems of backward production process, poor moisture resistance, wear resistance, large deformation, etc., achieve work performance optimization, avoid wrinkled foil, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Production equipment embodiment:

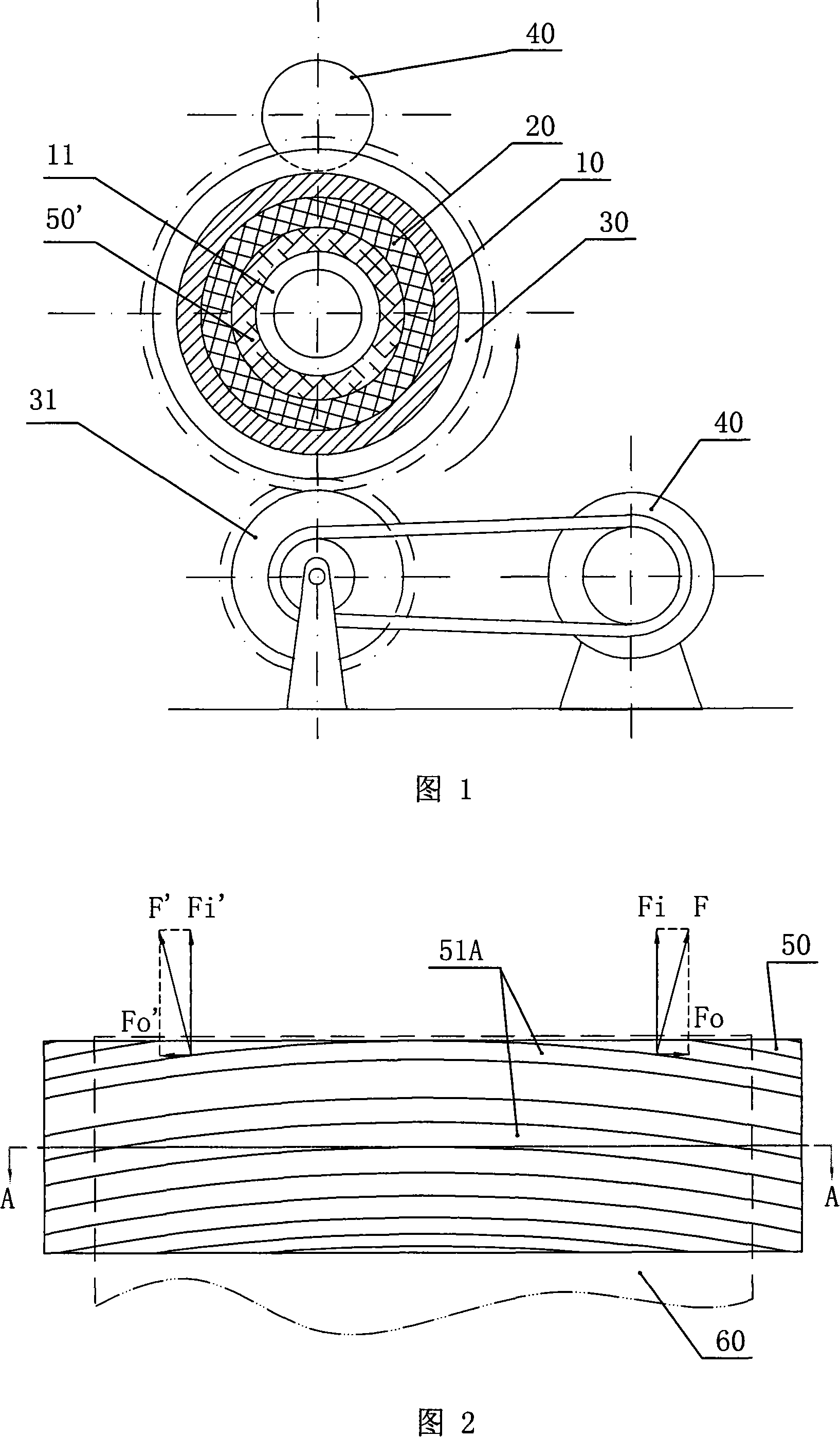

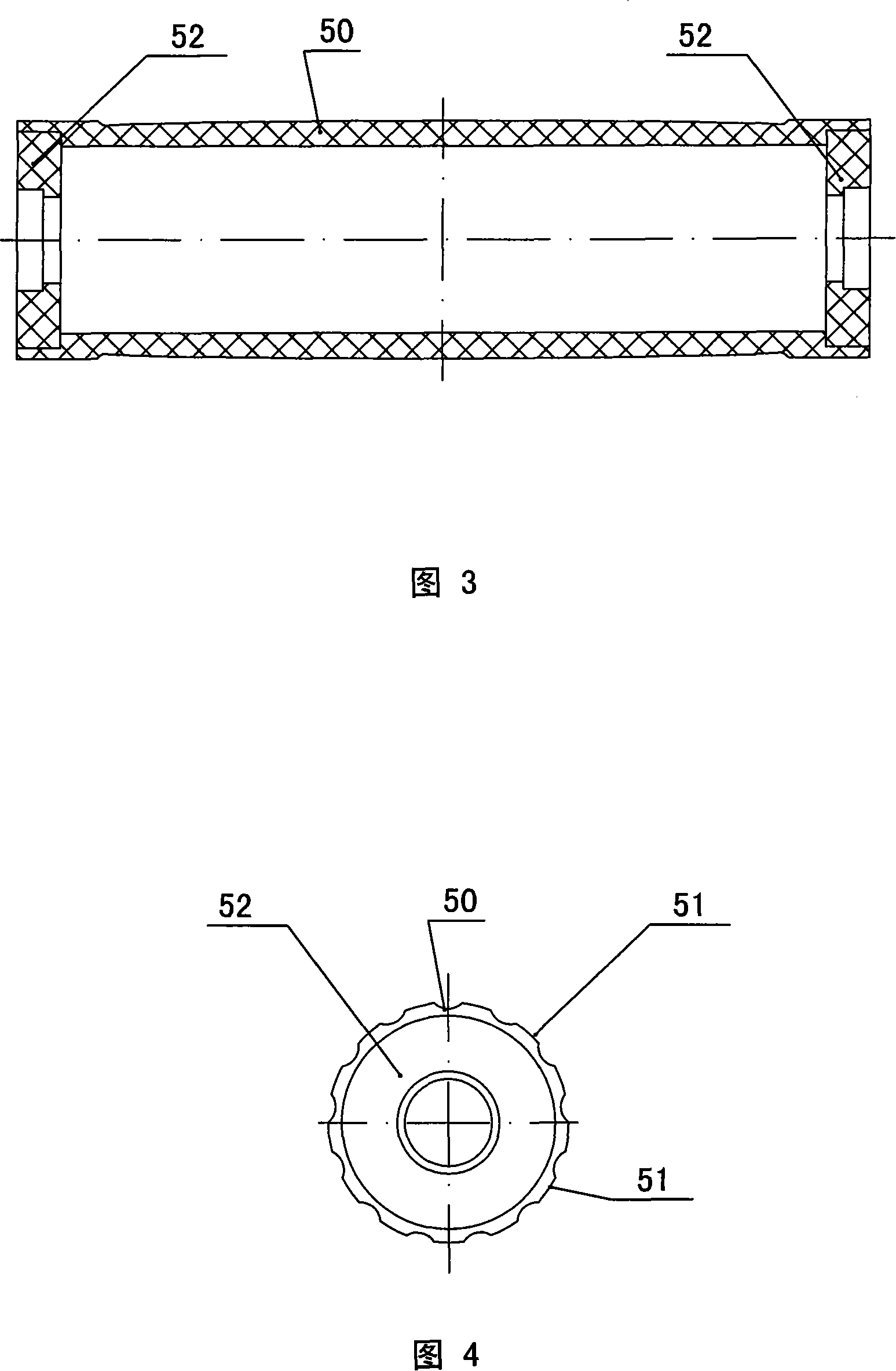

[0028] Fig. 1 is a schematic structural view of an embodiment of the production equipment of the present invention. It includes a molding die and a transmission device, and the production equipment also includes a horizontal rotating rigid drum 10, the molding die is an elastic colloidal negative film 20, and the colloidal negative film 20 is tightly fitted on the rigid rotary drum. In the cylinder 10, the transmission device includes a driven gear 30 that is fastened to the rigid cylinder 10 and drives it to rotate concentrically.

[0029] The longitudinal axis of the colloidal negative membrane 20 coincides with the longitudinal axis of the rigid drum 10, and the two ends of the rigid rotating drum 10 are also equipped with retaining rings 11 that limit the two ends of the colloidal negative membrane 20. The pore diameter of 11 is smaller than the inner diameter of the colloid negative membrane 20 .

[0030] The outer circumference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com