Heat-insulating clad plate

A technology of thermal insulation composite board and thermal insulation board, which is used in covering/lining, construction, building structure, etc., can solve the problems of large load on the facing brick facing layer, peeling off and peeling off of facing bricks, etc., so as to shorten the construction period on site and reduce the load of decoration. , The effect of simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

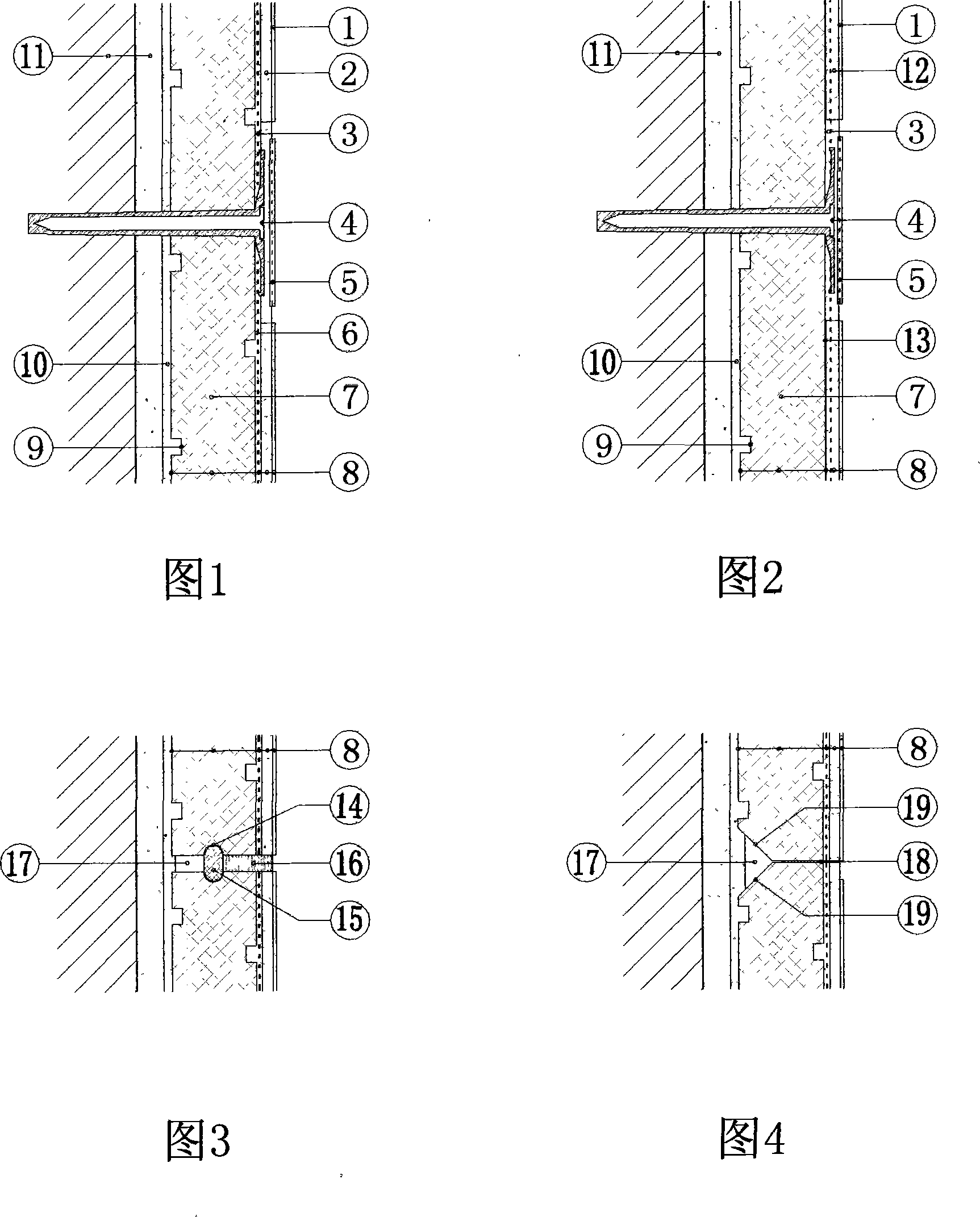

[0045] 1. Fig. 1 is a cross-sectional structure diagram of the first application example of the present invention - the cement sheet wherein does not have a reinforcing mesh

[0046]In Fig. 1, the imitation brick veneer layer (1) is made on the cement sheet (2) without reinforcement mesh, and the cement sheet (2) without reinforcement mesh is bonded with polymer cement mortar bonding layer (6) and The thermal insulation board (7) is bonded, and the polymer cement mortar bonding layer (6) is clothed with a reinforcing net (3), which is composed of a faux brick facing layer (1), a cement sheet without a reinforcing net (2), and reinforced The net (3), the polymer cement mortar bonding layer (6), and the thermal insulation board (7) are combined to produce the thermal insulation composite board (8) of the present invention. Wherein, the shallow holes or horizontal shallow grooves (9) on the insulation board (7) play the role of enhancing the shearing resistance.

[0047] The the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com