White light LED and lighting apparatus

A technology of LED chips and white light, applied in lighting devices, lighting and heating equipment, light sources, etc., can solve the problems of low luminous efficiency, low afterglow brightness of white LEDs, and few luminous colors, and achieve high luminous efficiency and excellent color rendering Sex, good color rendering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

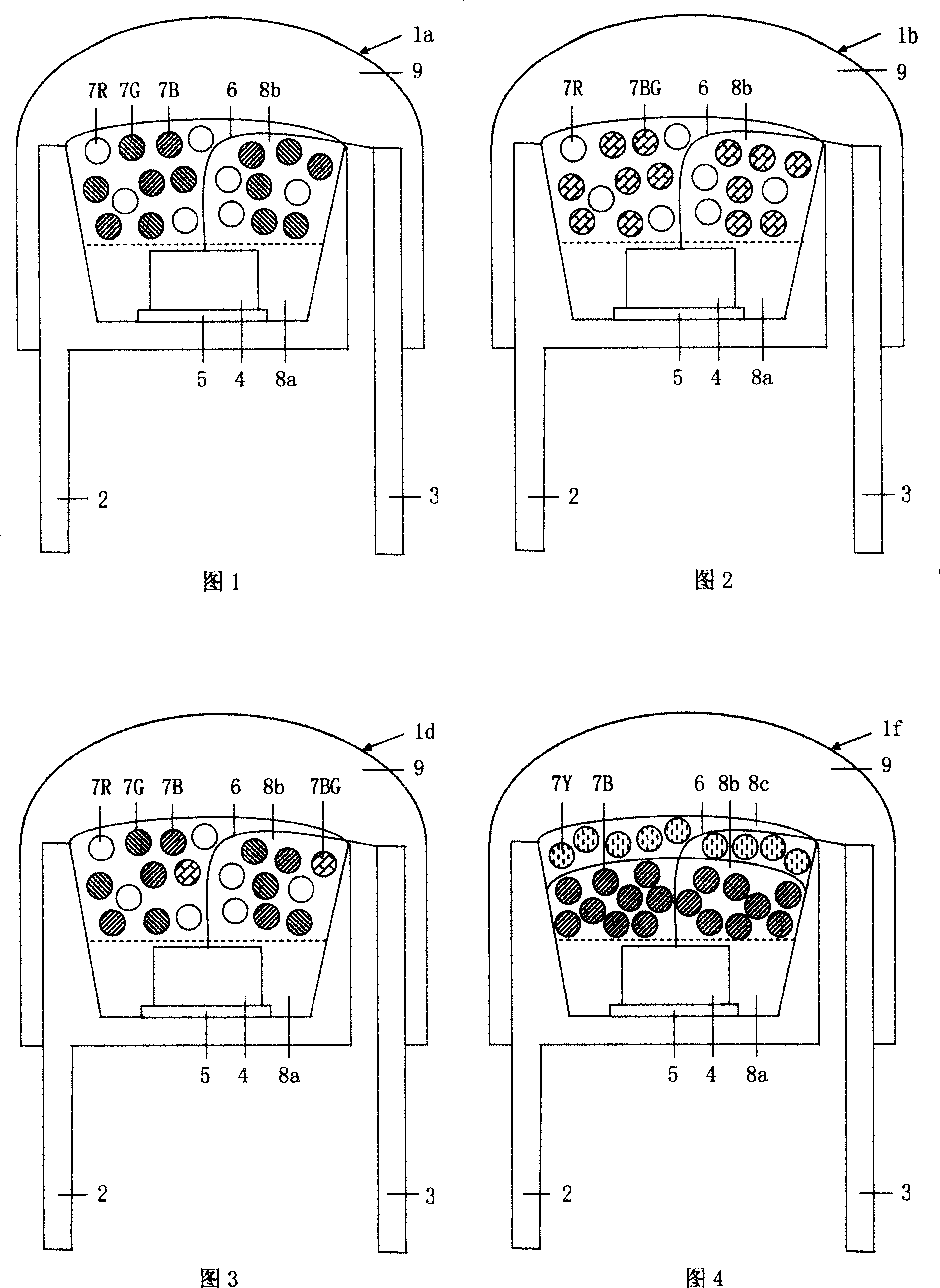

[0063] Fig. 1 is a cross-sectional view of a white LED 1a according to Embodiment 1 of the present invention.

[0064] White LED 1a consists of lead wires 2 and 3, ultraviolet LED chip 4 with a peak wavelength of 360nm to 400nm, conductive adhesive 5, bonding wire 6, red phosphor 7R, green phosphor 7G, blue phosphor 7B, resin 8a, 8b and resin 9 composition. A recess is provided on the lead wire 2, on which the ultraviolet LED chip 4 is placed. The ultraviolet LED chip 4 is electrically connected to the lead wire 2 through the conductive glue 5 , and is electrically connected to the lead wire 3 through the bonding wire 6 . The resin 8a covers the ultraviolet LED chip 4, and the resin 8b forms a phosphor layer with the red phosphor powder 7R, the green phosphor powder 7G and the blue phosphor powder 7B, covering the resin 8a. The resin 9 covers the upper parts of the leads 2 and 3, the bonding wire 6 and the resin 8b.

[0065] An example of the manufacturing method of white L...

Embodiment approach 2

[0070] Fig. 2 is a cross-sectional view of a white LED 1b according to Embodiment 2 of the present invention.

[0071] The only difference from the white LED 1a of Embodiment 1 is that in the white LED 1b of Embodiment 2, red phosphor 7R, green phosphor 7G, and blue phosphor 7B are replaced by blue-green phosphor 7BG and red phosphor 7R, for example, Sr 4 al 14 o 25 : Eu, Dy and (Ba, Ca, Mg) 10 (PO 4 ) 6 Cl 2 : Eu is a two-component blue-green phosphor 7BG, using Y 2 o 2 S: Eu is red phosphor 7R.

[0072] When LED1b is working, the ultraviolet LED chip 4 emits ultraviolet light, excites blue-green and red phosphors, and emits white light mixed with blue-green light and red light. After LED1b stops working, due to Sr 4 al 14 o 25 :Eu, Dy are light-storing phosphors, so they can continue to emit blue-green light. By regulating Sr 4 al 14 o 25 : Eu, Dy and (Ba, Ca, Mg) 10 (PO 4 ) 6 Cl 2 The weight ratio of :Eu can adjust the brightness of LED1b when working and...

Embodiment approach 3

[0074] Referring to FIG. 2 , white LED 1 c according to Embodiment 3 of the present invention will be described.

[0075] The only difference from the white LED 1b of Embodiment 2 is that in the white LED 1c of Embodiment 3, blue-green phosphor 7BG and red phosphor 7R are replaced by blue phosphor 7B and yellow phosphor 7Y, for example, Sr 10 (PO 4 ) 6 Cl 2 :Eu as blue phosphor, using Ca 2 MgSi 2 o 7 : Eu, Dy and (Sr, Ba) 2 SiO 4 : Eu as a two-component yellow phosphor.

[0076]When the LED1c is working, the ultraviolet LED chip 4 emits ultraviolet light, excites blue and yellow phosphors, and emits white light mixed with blue light and yellow light. After LED1c stops working, due to Ca 2 MgSi 2 o 7 :Eu, Dy are light-storing phosphors, so they can continue to emit yellow light. By regulating Ca 2 MgSi 2 o 7 : Eu, Dy and (Sr, Ba) 2 SiO 4 : The weight ratio of Eu can adjust the brightness of LED1c when it is working and the afterglow brightness and afterglow tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com