Electromagnet horizontal mobile section steel automatic packing machine

An automatic packaging machine and horizontal movement technology, applied in the direction of packaging, transportation and packaging, conveyor objects, etc., can solve the problems of increasing electromagnet spare parts storage, low manpower lifting efficiency, complex electromagnet structure, etc., to increase spare parts storage , Saving spare parts storage expenses, the effect of fast working frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

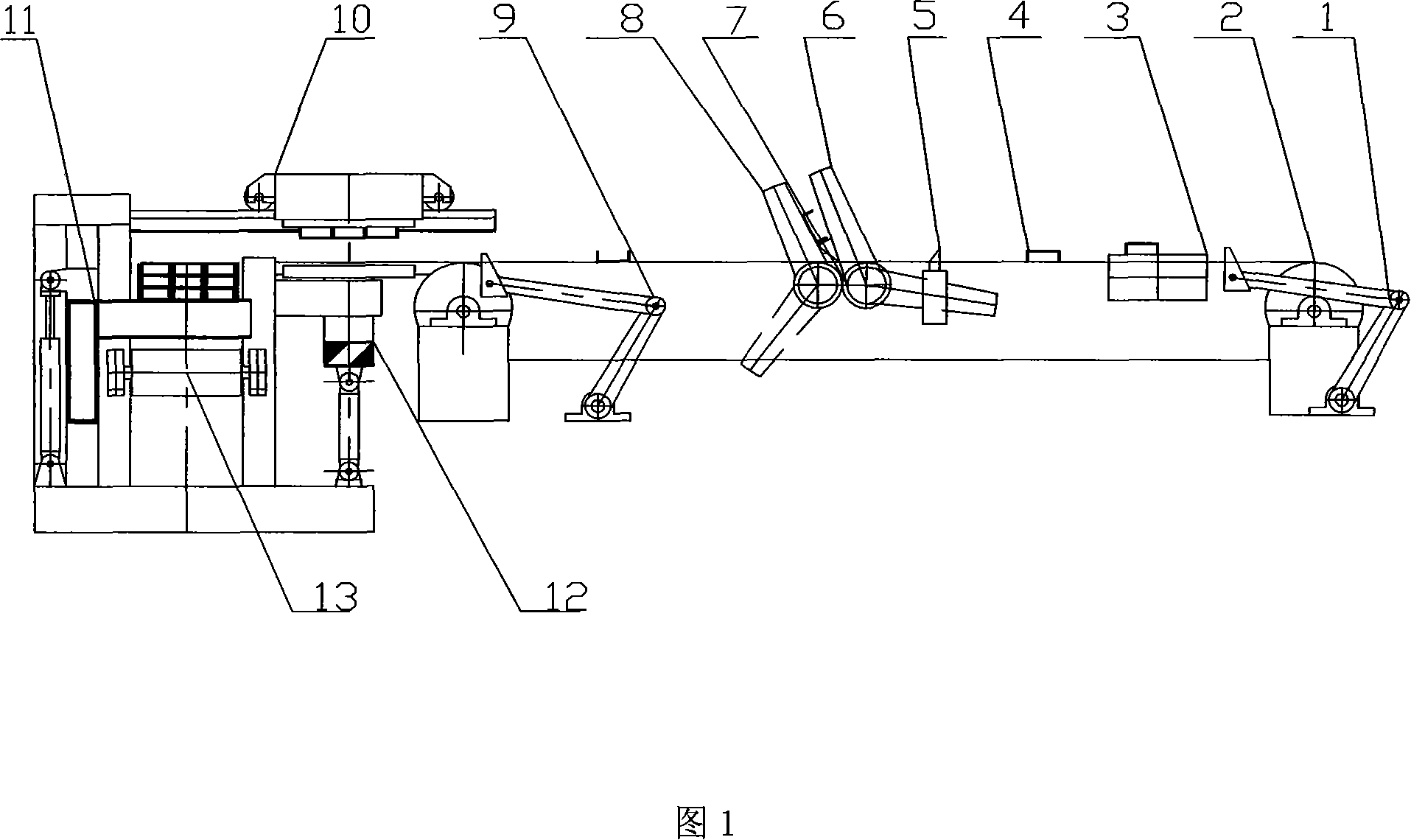

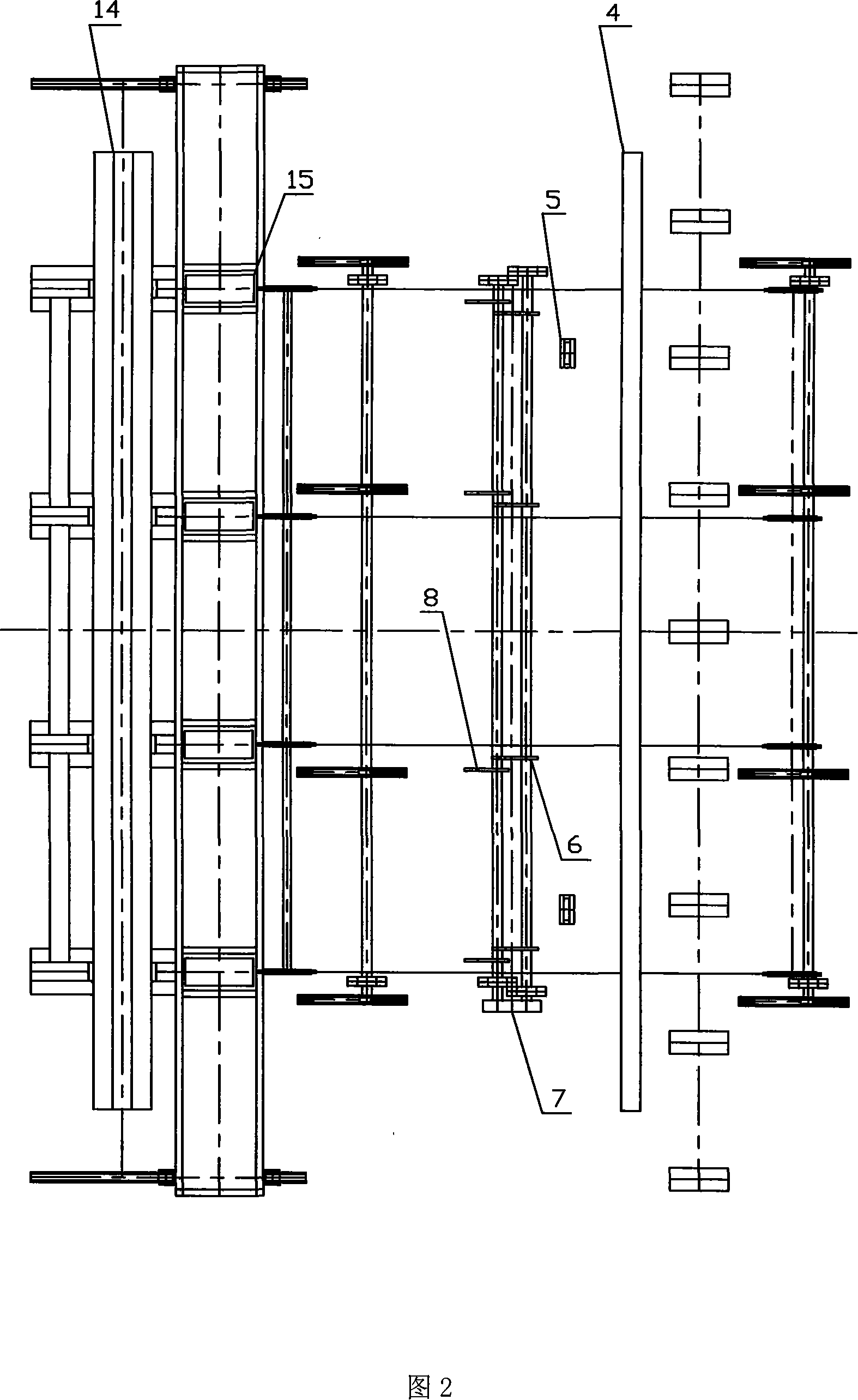

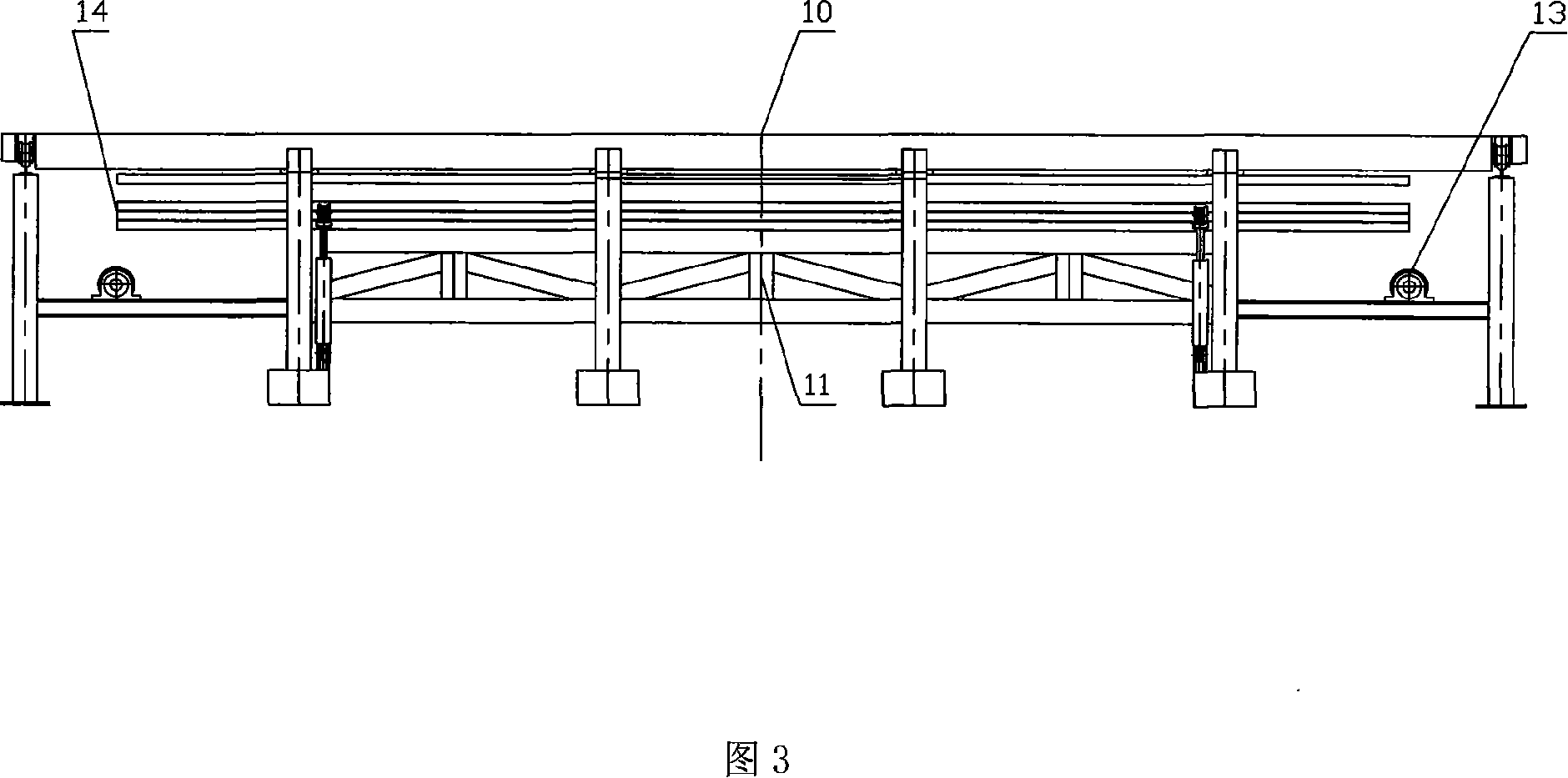

[0021] An electromagnet horizontally moving type steel automatic packaging machine, the device is composed of several separate parts: a single-row steel lifting mechanism 12, an electromagnet trolley 10, a piled steel lifting mechanism 11, a steel tight device 9, and a steel turning mechanism. The single-row shaped steel lifting mechanism 12 is located at the end of the chain conveying mechanism 2, and its upper part is provided with a track on which a horizontally moving electromagnet trolley 10 is arranged; the stacked shaped steel lifting mechanism 11 is arranged on the top of the stacked shaped steel output roller table 13 . The end of the chain conveying mechanism 2 is provided with a profiled steel abutment device 9; the chain conveying mechanism 2 is provided with a profiled steel overturning mechanism, and the profiled steel overturning mechanism is sent by the overturning mechanism to the steel arm 6, the overturning mechanism gear shaft 7, and the overturning mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com