Catalyst composition applied to producing syndiotactic polystyrene material

A polystyrene and composition technology, which is applied in the field of catalyst compositions for producing syndiotactic polystyrene materials, can solve the problems of high manufacturing cost of aluminoxane, limit the feasibility of catalyst commercialization and the like, and achieves reduction of manufacturing cost, The effect of reducing the cost of styrene polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

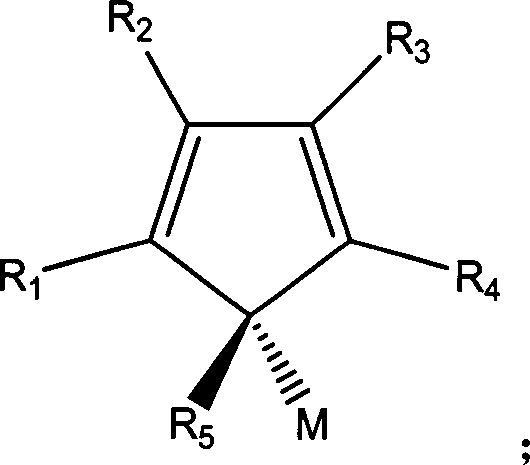

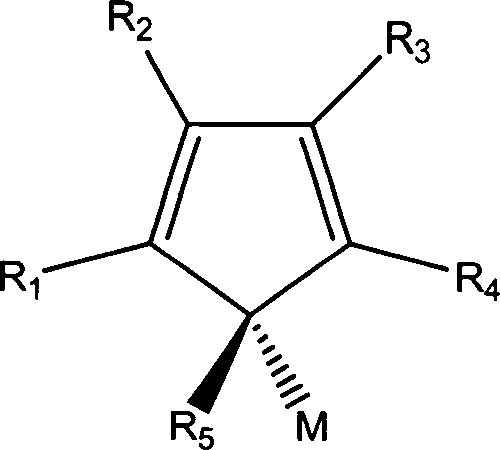

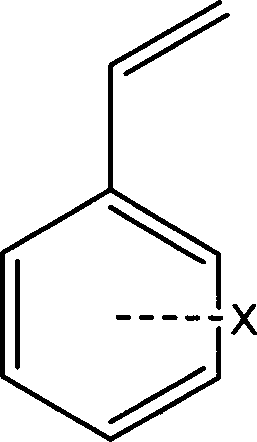

Method used

Image

Examples

Embodiment 1

[0068] In Example 1, the polymerization of styrene monomer was carried out in a 500 mL (milliliter) stainless steel reactor (Parr Reactor) with an electric stirring device. The reactor was first charged with 100 mL of styrene monomer, then aluminoxane (MAO, 6.6 mmole (mole) Al), the reaction temperature was raised to 60 ° C, and then 0.75 mL of tetraethoxyalkyltitanium (Ti( OEt) 4 , 1.6×10 -2 M (mole) dissolved in toluene (toluene)) and 0.75mL of 1-butylcyclopentadienyl lithium (1.6×10 -2 M dissolved in toluene), to start the polymerization reaction. The reaction was carried out at 60° C. for 30 minutes, and then methanol was added to terminate the reaction. The resulting white solid of syndiotactic polystyrene was separated by filtration and dried under reduced pressure (80° C.) to obtain 10.2 g of the product (catalyst activity=1.7×10 6 g.sPS / mole.Ti.hr (every gram of syndiotactic polystyrene / every mole of titanium. per hour)), this syndiotactic polystyrene product is ana...

Embodiment 2

[0070] In Example 2, the polymerization reaction of styrene monomer was carried out in a 500 mL stainless steel reactor with an electric stirring device. The reactor was first charged with 100 mL of styrene monomer, then aluminoxane (6.6 mmole Al), the reaction temperature was raised to 70 ° C, and then 0.75 mL of triisopropoxy titanium chloride (ClTi(O i Pr) 3 , 1.6×10 -2 M dissolved in toluene) and 0.75mL of lithium pentamethylcyclopentadienyl (1.6×10 -2 M suspended in toluene), to start the polymerization reaction. The reaction was carried out at 70° C. for 10 minutes, then methanol was added to terminate the reaction, and the syndiotactic polystyrene white solid generated was separated by filtration and dried under reduced pressure (80° C.) to obtain 13.7 g of the product (catalyst activity=6.9×10 6 g.sPS / mole.Ti.hr), the syndiotactic polystyrene product is analyzed by carbon 13 nuclear magnetic resonance, and its syndiotacticity (racemic pentad (rrrr)) reaches 96%. In...

Embodiment 3

[0072] In Example 3, the polymerization reaction of styrene monomer was carried out in a 500 mL stainless steel reactor with an electric stirring device. The reactor was first charged with 100 mL of styrene monomer, then aluminoxane (6.6 mmole Al), the reaction temperature was raised to 70 ° C, and then 0.75 mL of tetra-n-butoxy titanium (Ti(O n Bu) 4 , 1.6×10 -2 M dissolved in toluene) and 0.75 mL of 1-butylindenyl sodium (1.6×10 -2 M suspended in toluene), to start the polymerization reaction. The reaction was carried out at 70° C. for 30 minutes, then methanol was added to terminate the reaction, and the syndiotactic polystyrene white solid generated was separated by filtration and dried under reduced pressure (80° C.) to obtain 8.60 g of the product (catalyst activity=1.4×10 6 g.sPS / mole.Ti.hr), the syndiotactic polystyrene product is analyzed by carbon 13 nuclear magnetic resonance, and its syndiotacticity (racemic pentad (rrrr)) reaches 92%. Further, in order to exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com