Processing device for processing fluid and substrate processing device having the same

A substrate processing device and processing device technology, applied in ion exchange processing devices, chemical/physical processes, ion exchange regeneration, etc., can solve the problem of precipitation, the precipitation adheres to the inner surface of the storage tank or adheres in the form of particles On the substrate, the cost of etching processing increases, the efficiency of substrate processing decreases, etc., to achieve the effect of improving yield and substrate processing efficiency, suppressing substrate processing costs, and preventing defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

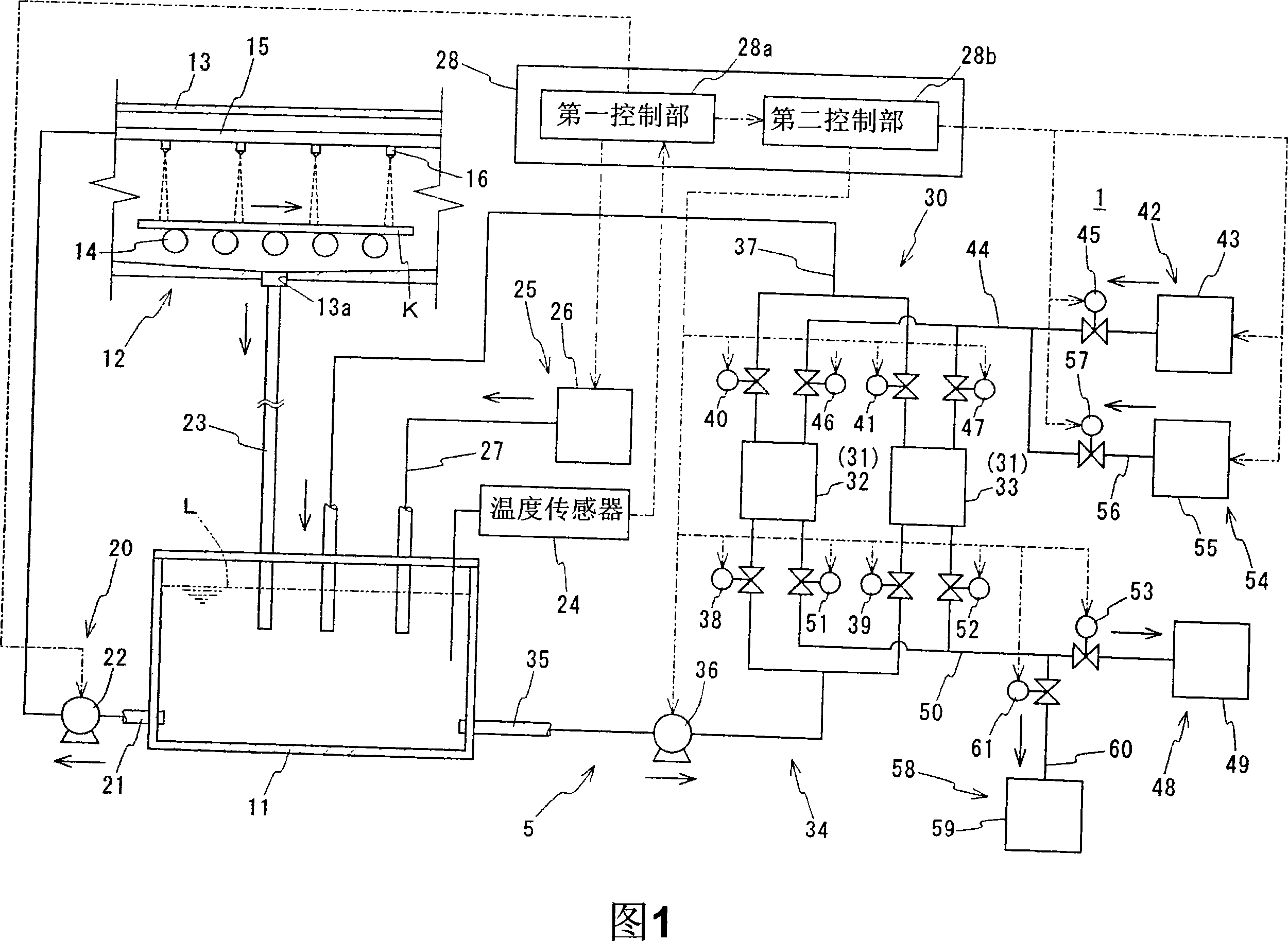

[0052] Hereinafter, specific embodiments of the present invention will be described with reference to the accompanying drawings. Among them, FIG. 1 is a structural diagram schematically showing the structure of a substrate processing apparatus according to an embodiment of the present invention.

[0053] As shown in FIG. 1 , the substrate processing apparatus 1 of this example uses, for example, an etchant L having an oxalic acid concentration (weight %) of about 3%, to etch a substrate K on which an indium tin oxide film (metal film) is formed on the upper surface. , comprising: a storage tank 11 for storing etching solution L, a substrate processing mechanism 12 utilizing etching solution L to etch substrate K, a first etching solution circulation mechanism (etching solution L) circulating between storage tank 11 and substrate processing mechanism 12 for etching solution L Circulation mechanism for processing) 20, removal mechanism 30 for removing indium and tin (metal) diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com