[0007] 1. Because there is a big obstacle in plugging the LED from top to bottom, it is easy to break the connecting wire when plugging the LED

[0008] 2. In addition, there is another problem that when the product is repaired when some LEDs are not bright, it is usually to

cut the

coating layer from the bottom of the product with a knife to replace the LED in the core strip shape, but when placing the connecting wire through the The hole is set in the middle of the cross-section of the strip, and the upper side wall of the through hole is

cut longitudinally to form a slit. Therefore, in this structure, the LED and the connecting wire can only

cut the

coating layer and the

astigmatism from the top of the product, which is very difficult. , and after the product is repaired, it is easy to leave

scars on the luminous surface of the product, which affects the appearance

[0009] 3. Since each LED is connected in series by wires, the LEDs are welded and connected in series by wires, and then the resistors and the connecting wires between the LEDs are inserted into the longitudinal slots, and the resistors connected in series between the LEDs are plugged. into the two horizontal circular holes set between the horizontal hole and the horizontal hole. Since the length of the connecting wire between the LED and the LED must be greater than the distance between the horizontal hole and the horizontal hole, the connecting wire is inserted into the longitudinal groove in a roundabout way. State, so there is no more space to place resistors in the longitudinal groove, so this technology product has two horizontal circular holes between the horizontal holes in the structure to place the resistors, so it also increases the manufacturing process , if the longitudinal slot is enlarged to place the

resistor, then the distance between the LEDs placed in the longitudinal slot and the connecting wires between the LEDs will increase, so the connections will appear when the product is bent in the transverse direction. The winding paths of the wires are different, which leads to the connection of the wires, and if the connecting wires connected to one or both ends of the

resistor are broken during use, there will be two connecting wires touching together and conducting current, so the LED has no series resistance. will

burn in case

[0010] 4. Since the LED and the LED and the

resistor are welded by connecting wires, they cannot be welded automatically by

mechanization, and they need to be inserted into the corresponding horizontal holes, so a lot of labor is required in the production, which has the

disadvantage of high cost

[0011] The same inventor, Ben Fan, also invented a

Chinese patent application number: 200420093781.5, PCT

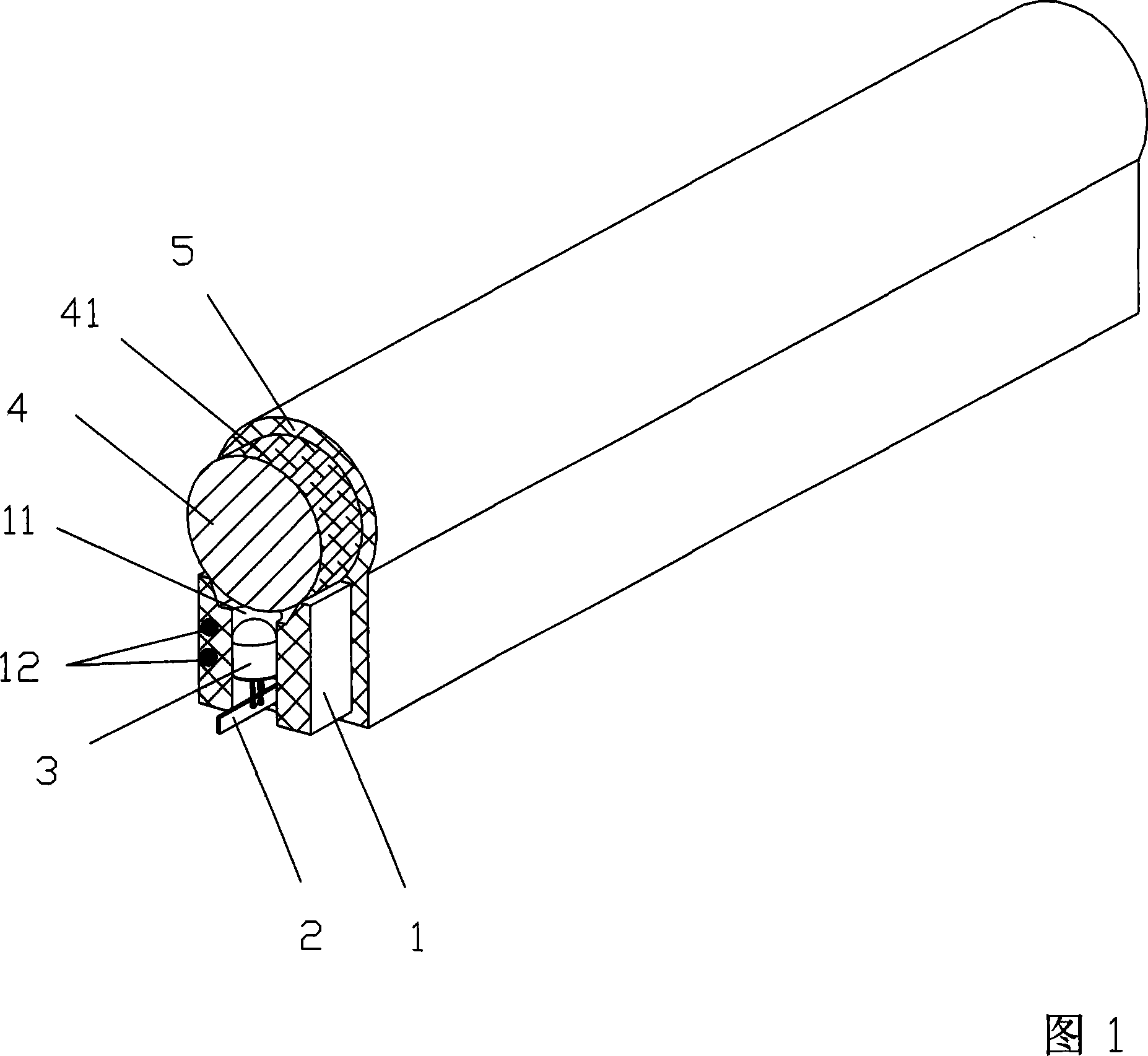

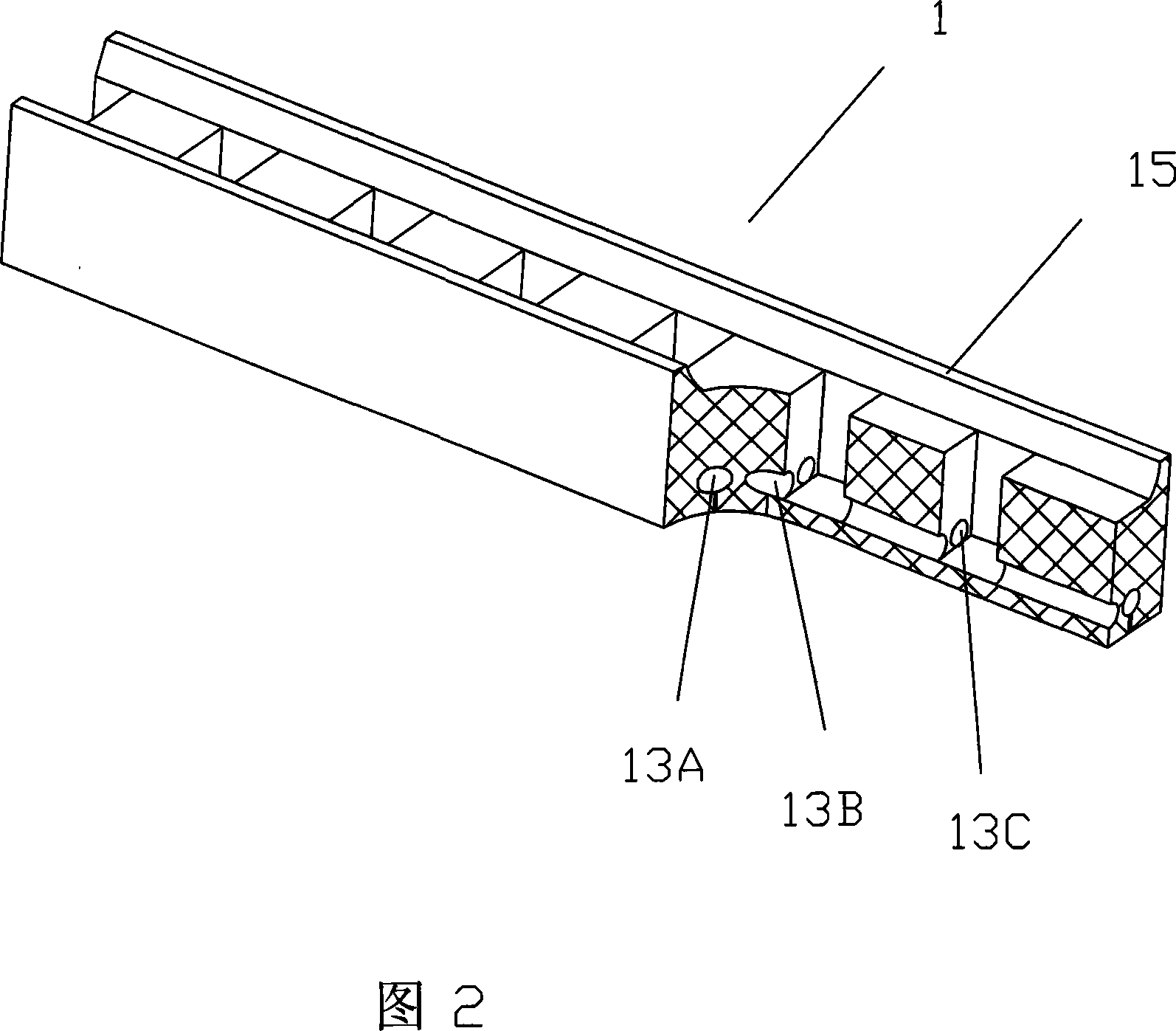

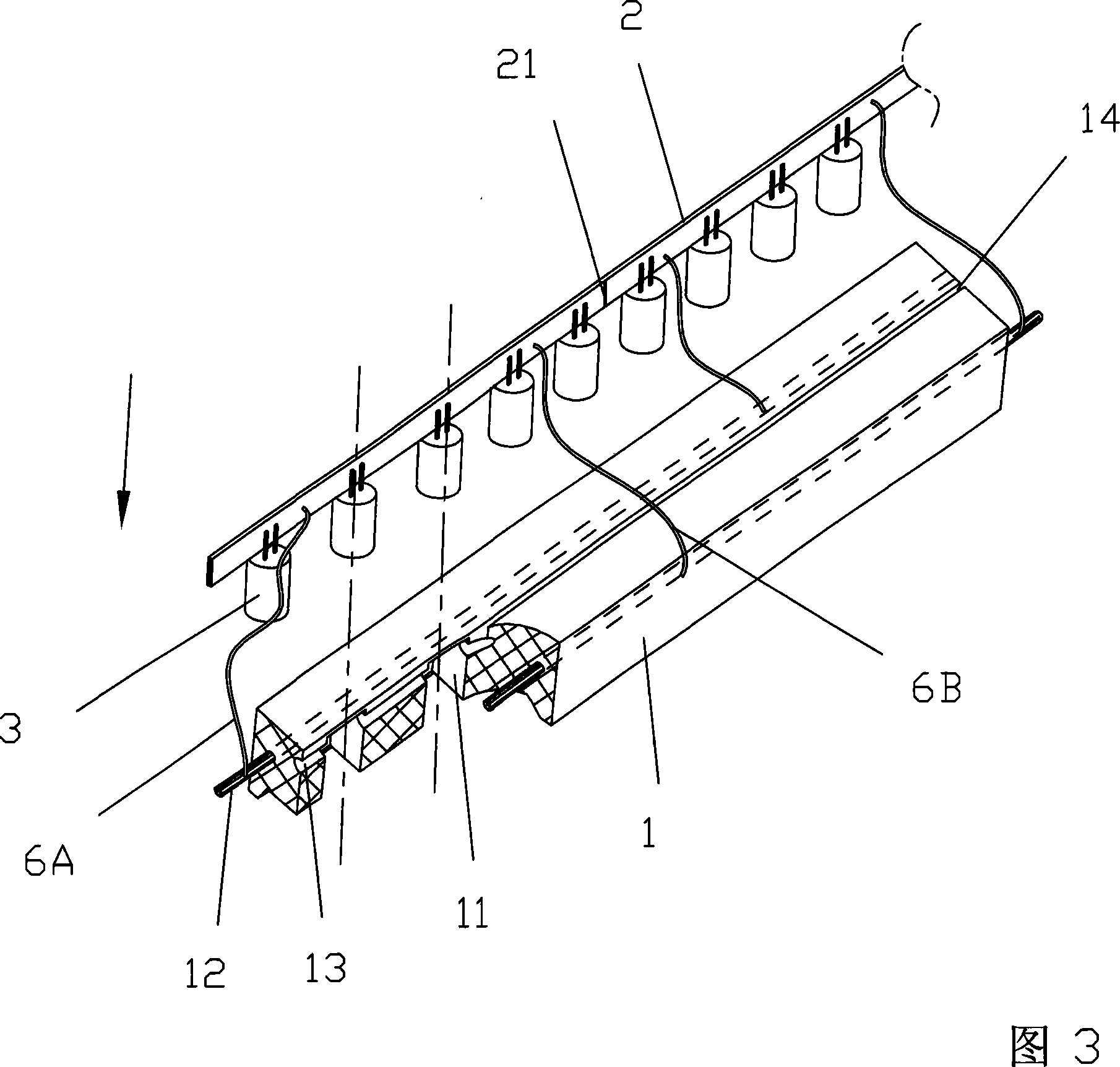

patent application number: CN2005 / 000176, and the name is "an improved structure of a hose lamp". This invention discloses a flexible plastic

extrusion The cross-section of the formed predetermined length is a rectangular strip, and the strip is provided with a rectangular through hole inside it along the longitudinal direction, and a plurality of flexible strip circuit boards with several LEDs are vertically arranged on the strip In the rectangular through hole in the body, a milky white opaque but light-transmitting

astigmatism body is arranged above the above-mentioned LED

bulb, and a

coating layer is coated on the above-mentioned rectangular strip and the

astigmatism body, and the coating layer is integrated with the above-mentioned astigmatism body , although this invention solves the shortcomings of the above-mentioned invention that are not resistant to bending and the production process is cumbersome, the invention has the following disadvantages:

[0012] 1. Since the LEDs set on the flexible strip circuit board in this technology only rely on the flexible circuit board to fix the distance between the LEDs, but the circuit board is flexible, the LEDs are easy to shift during bending and use, resulting in two Even multiple LEDs are squeezed together, resulting in the defect that the product emits uneven light

[0013] 2. Since the flexible strip-shaped circuit board is set vertically in the rectangular through hole in the strip in this technology, the product cannot be bent in the longitudinal direction, especially when the product needs to be wound on a column for use The flexible ribbon circuit board is easy to break when it is not even bent

[0014] 3. Since the two ends of the flexible ribbon circuit board in this technology are only limited to connect with the

copper strands in the rectangular strip through connecting wires, when the length of each unit is small, all the flexible ribbon circuits need to be connected When the board is connected to the

copper stranded wire, there are defects of cumbersome process, time-consuming and high cost

[0015] 4. Since the connecting wires connecting the flexible strip circuit board and the

copper stranded wire in this technology are arranged at both ends of each unit, since the user cuts the length of the unit according to the needs when the product is in use, when the LED and the LED If the spacing is small, if there is a slight deviation when

cutting, the connecting wire will be cut, so it is easy to produce waste products

Login to View More

Login to View More  Login to View More

Login to View More