Pressing ball forming method and device

A molding device and molding method technology, applied in the direction of mold extrusion granulation, etc., can solve the problems of difficult demoulding, low work efficiency, and high processing costs, and achieve the effects of stable and reliable molding process, improved product quality, and reduced processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

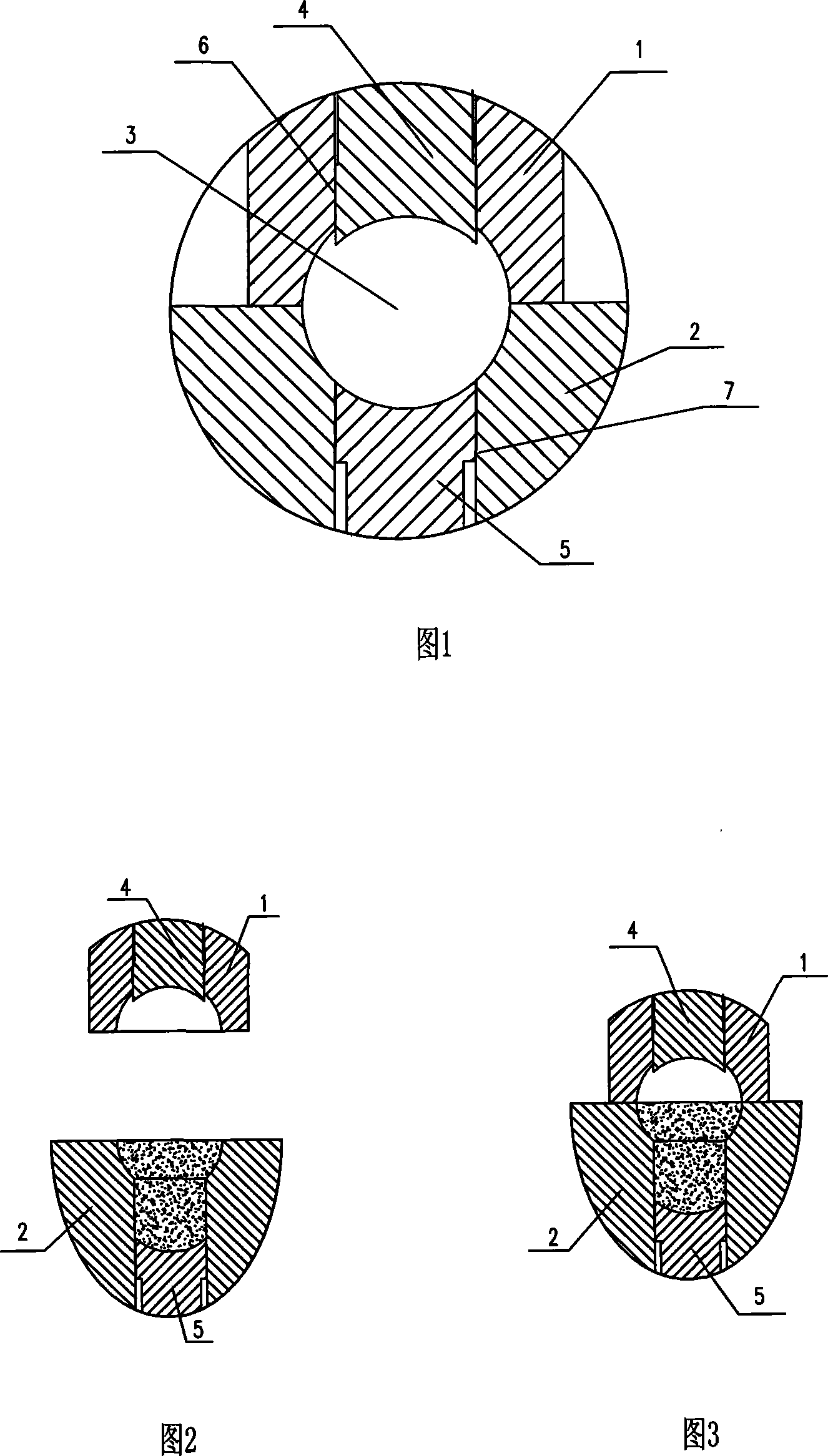

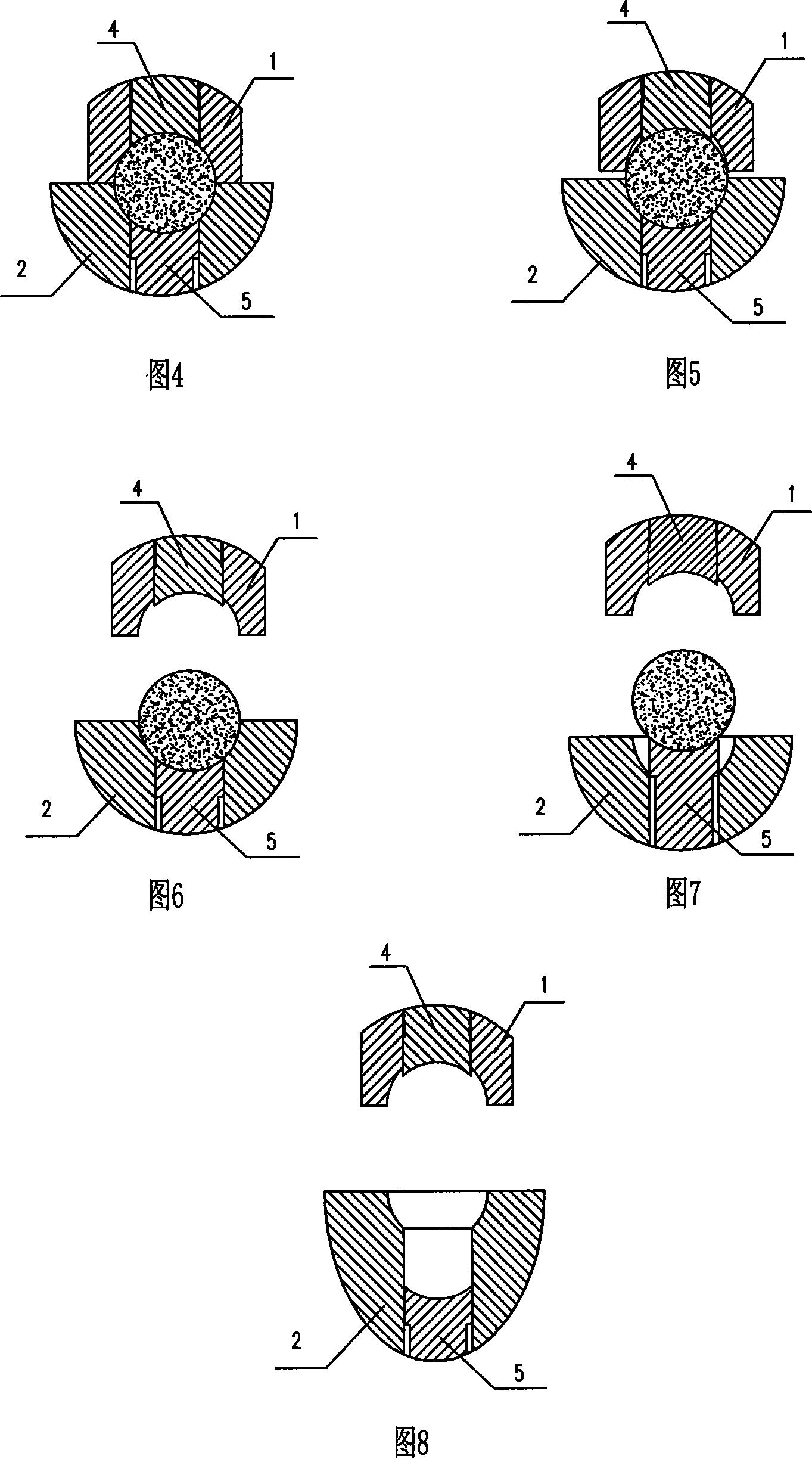

[0033] As shown in Figures 2 to 8, a pressing ball molding method of the present invention is to add upper and lower mold cores respectively in the upper and lower mold frames of the existing pressing ball molding device, and through the upper and lower mold frames The mold core moves longitudinally, and the powder fed into the mold frame is pressed into a spherical body and the demoulding process is completed.

[0034] Described pressing ball molding method, it comprises following production steps:

[0035] a. The lower mold frame moves upward relative to the lower mold core, so that the upper part is a hemisphere, and the lower part is a cylinder;

[0036] b. Loading, sending the powder required for pressing the entire sphere into the material-holding cavity formed through the process of (a);

[0037] c. The upper die is connected downward to the lower die frame;

[0038] d. For ball forming, the upper mold continues to move downward, and drives the lower mold frame to mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com