A pulse constant energy charging method and its charging device for lead acid battery

A lead-acid battery and charging device technology, applied in battery circuit devices, secondary battery charging/discharging, circuit devices, etc., can solve the problem of not being able to achieve the best charging mode of lead-acid batteries, limiting the service life of lead-acid batteries, and adversely affecting batteries. Service life and other issues, to avoid soft failure, low cost and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

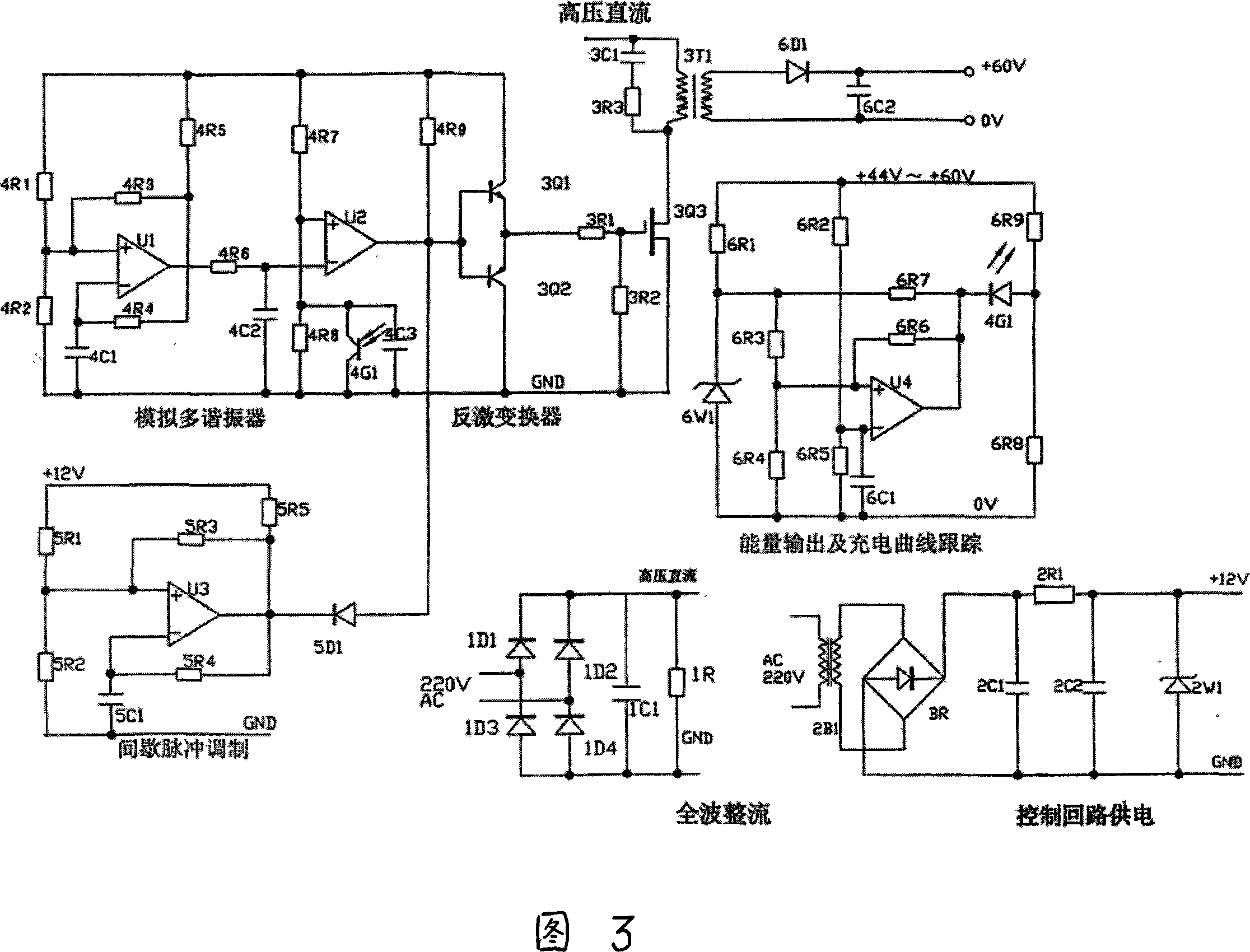

[0021]The AC 220V voltage is rectified by the rectifier bridge stack in the full-wave rectifier circuit and converted into a DC 310V working power supply through capacitor filtering, which supplies power to the flyback voltage converter. The AC 220V voltage is also passed through the transformer in the power supply control unit After 2B1 is stepped down, it is rectified by the rectifier bridge BR, filtered by capacitors 2C1 and 2R1, and stabilized by the regulator tube 2W1 to provide +12 volts to the entire control circuit; the voltage comparator U1 in the multivibrator uses LM339, multivibrator The oscillation frequency of the oscillator is determined by 4R4 and 4C1, about 50KHZ, and 4R5 is a pull-up resistor. 4R6 and 4C2 transform the output waveform of U1 so that the negative phase input of U2 is a triangle wave. Under the action of 4R7 and 4R8, the pulse width output by U2 is controlled by the optocoupler 4G1. When 4G1 is turned on, the pulse width output by U2 will gradua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com