Tunnel lining component high-temperature mechanical property testing system

A test system and high-temperature mechanics technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of manual temperature control, increase the maximum temperature, and slow heating speed, etc., to achieve improvement Work efficiency and data accuracy, the effect of high maximum temperature and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

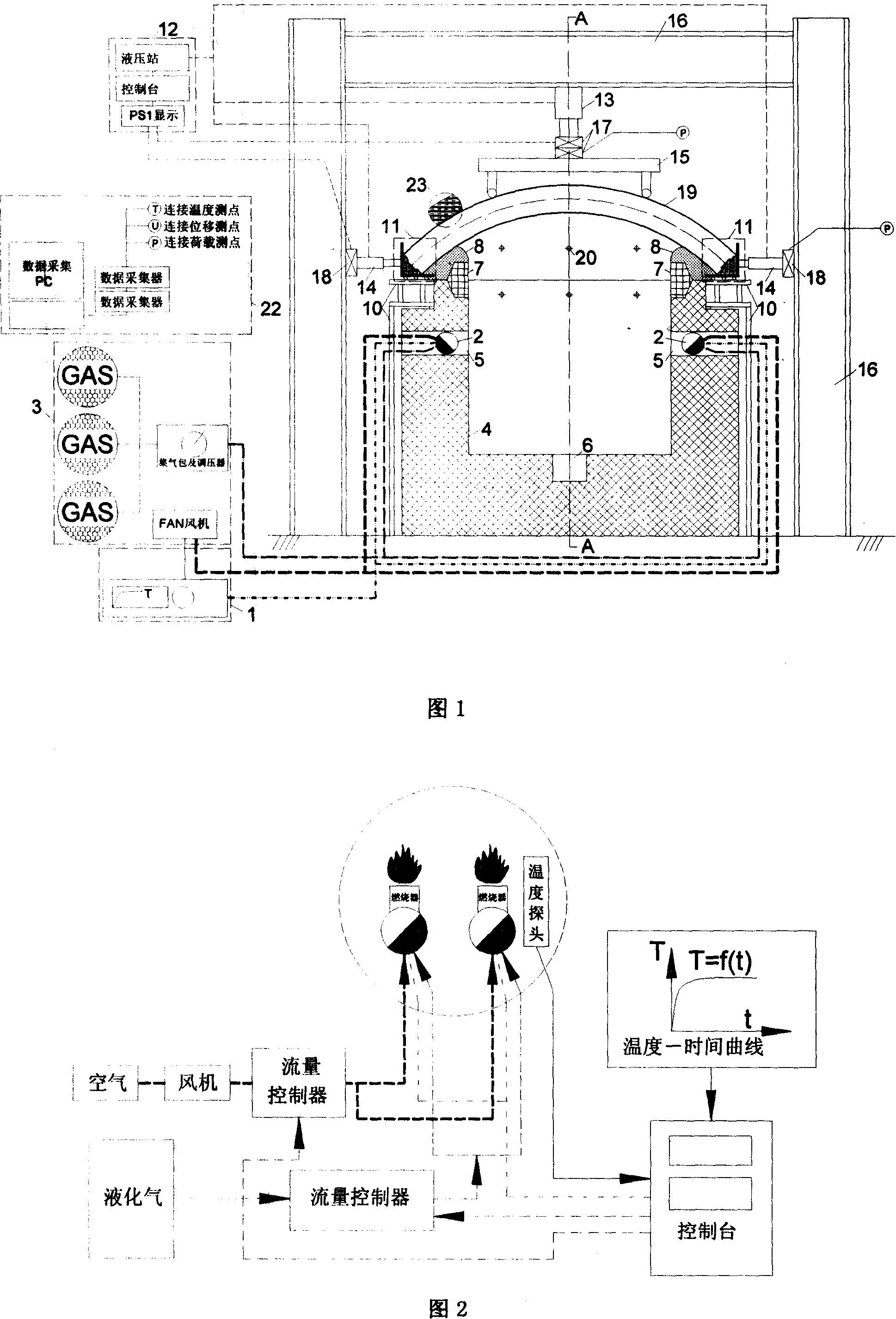

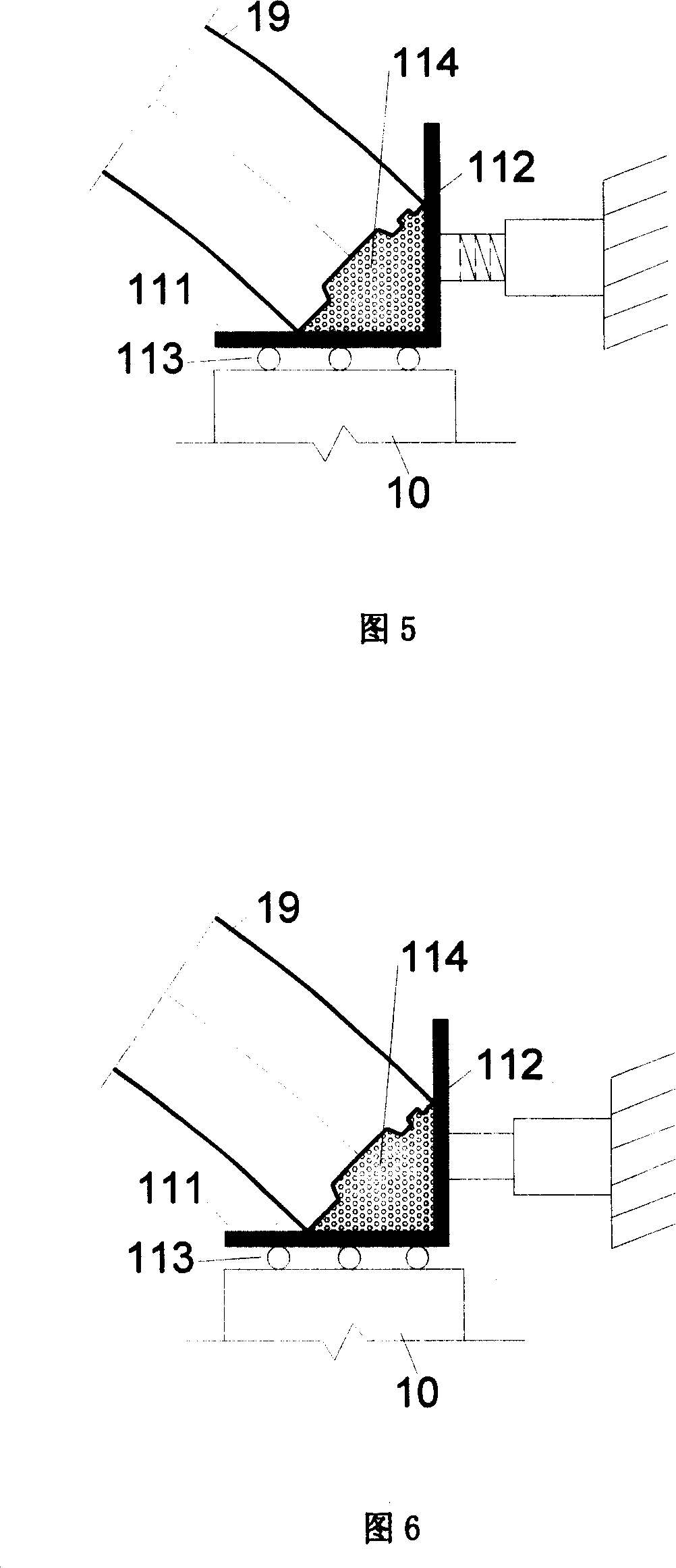

[0024] As shown in Figure 1, the high temperature mechanical performance test system of tunnel lining components of the present invention consists of the following seven subsystems:

[0025] (1) Fire thermal environment simulation subsystem;

[0026] (2) Thermal insulation subsystem;

[0027] (3) Mechanical boundary simulation subsystem of support and lining components;

[0028] (4) loading subsystem;

[0029] (5) Measurement subsystem;

[0030] (6) Data acquisition subsystem;

[0031] (7) Thermal boundary simulation subsystem of lining components.

[0032] The following is a detailed introduction to each subsystem:

[0033] 1. Fire thermal environment simulation subsystem

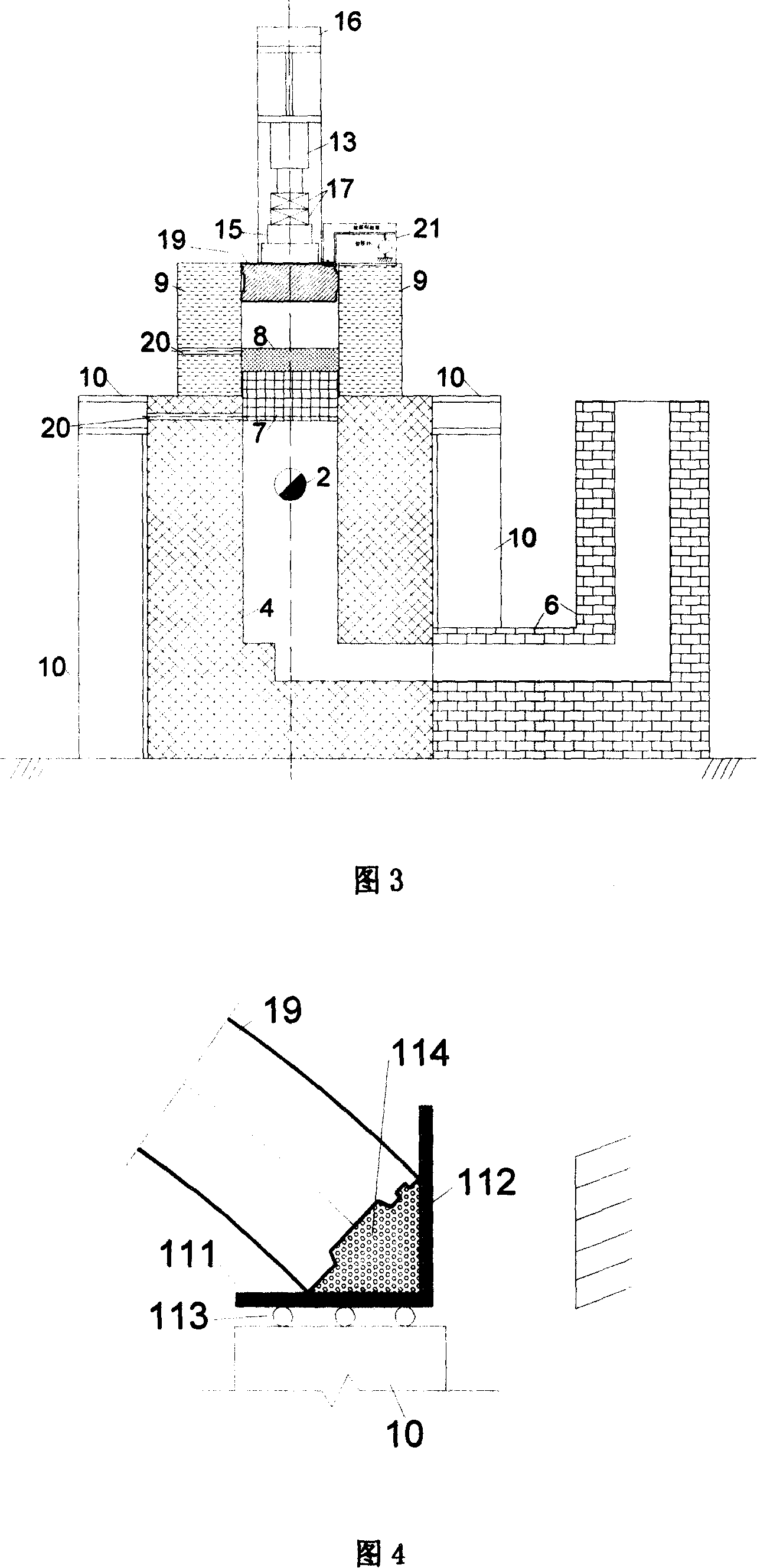

[0034] The fire thermal environment simulation subsystem mainly includes: burner console 1, burner 2, liquefied gas and air supply equipment 3, and the burner 2 is installed in the burner installation hole 5 reserved on the furnace 4.

[0035] The operating principle of the fire thermal environment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com