Multi-level material balance data correction method for petroleum refinery

A data correction and material balance technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve problems such as unsatisfactory, error detection and processing rely on human experience, etc., to avoid pathological problems, avoid Destructive effects, effects that facilitate data integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

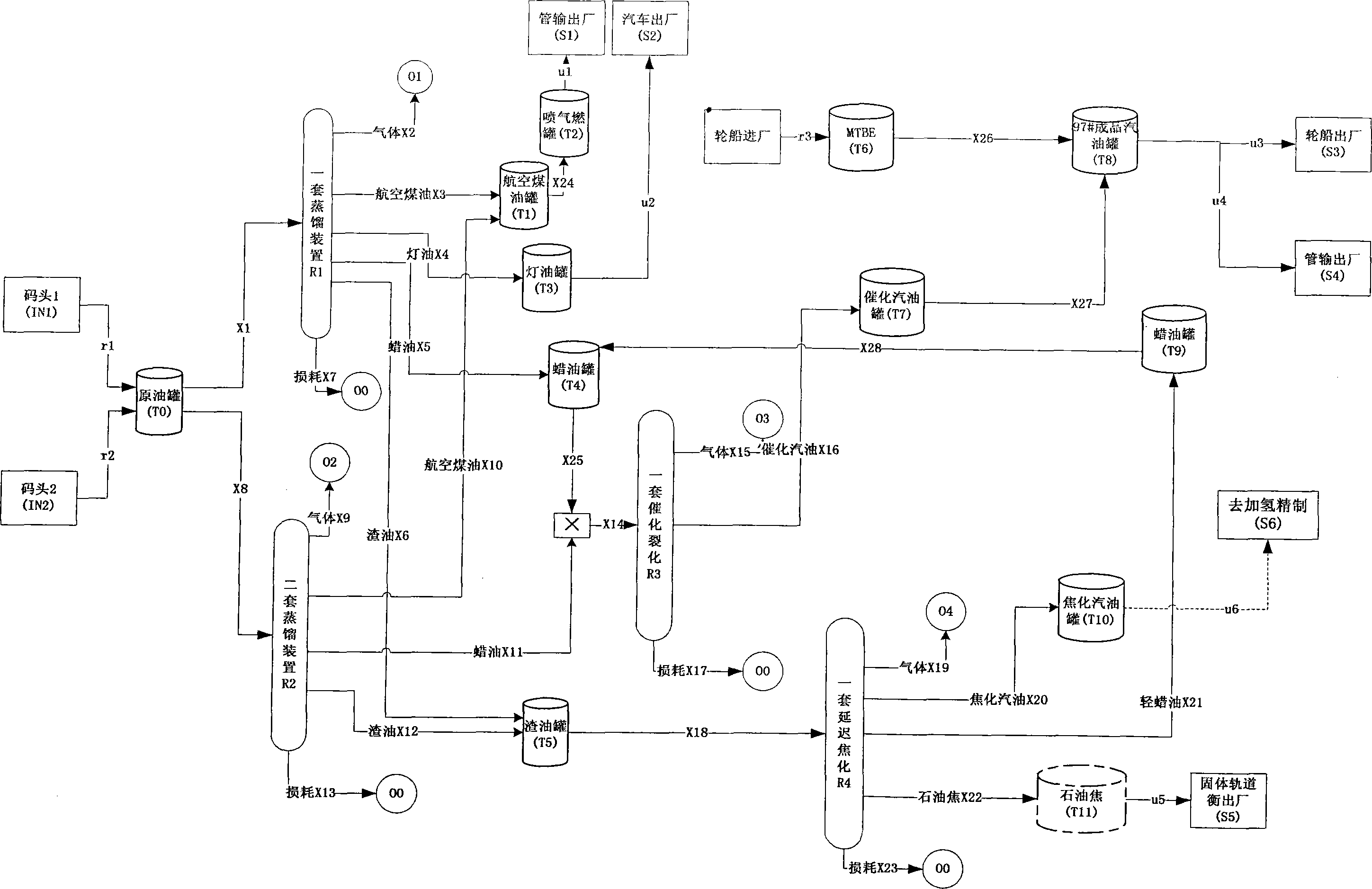

[0032] The specific implementation steps of the method will be described by taking the production flow diagram of a certain oil refinery shown in the accompanying drawings as an example.

[0033] 1) Number each incoming raw material stream as: r 1 r 2 r 3 ; The logistics number of each ex-factory product is: u 1 u 2 u 3 u 4 u 5 u 6 ;The number of intermediate logistics except inbound and outbound logistics is: x 1 x 2 x 3 ......x 28 , these intermediate streams include the loss of each production unit; number the change of each storage tank as: t 0 t 1 t 2 ......t 11 ;

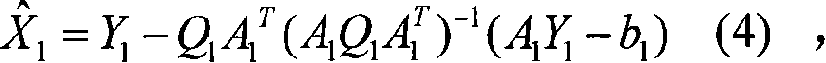

[0034] 2) Establish the balance equation of the purchase, sale and storage level of the whole plant:

[0035] A 1 x 1 =b 1

[0036] Among them, X 1 is a column vector composed of the storage tank variation and device loss marked in step 1):

[0037] x 1 =[x 7 x 13 x 17 x 23 x 2 x 9 x 15 x 19 t 0 t 1 t 2 t 3 t 4 t 5 t 6 t 7 t 8 t 9 t 10 t 11 ] T , A 1 is a row vector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com