Electric cable industry-control winding inserter

A cable and industrial control technology, applied in the field of cable industrial control off-line machine, can solve the problems of unguaranteed product quality, high labor intensity, and low efficiency, and achieve high production efficiency, convenient operation, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

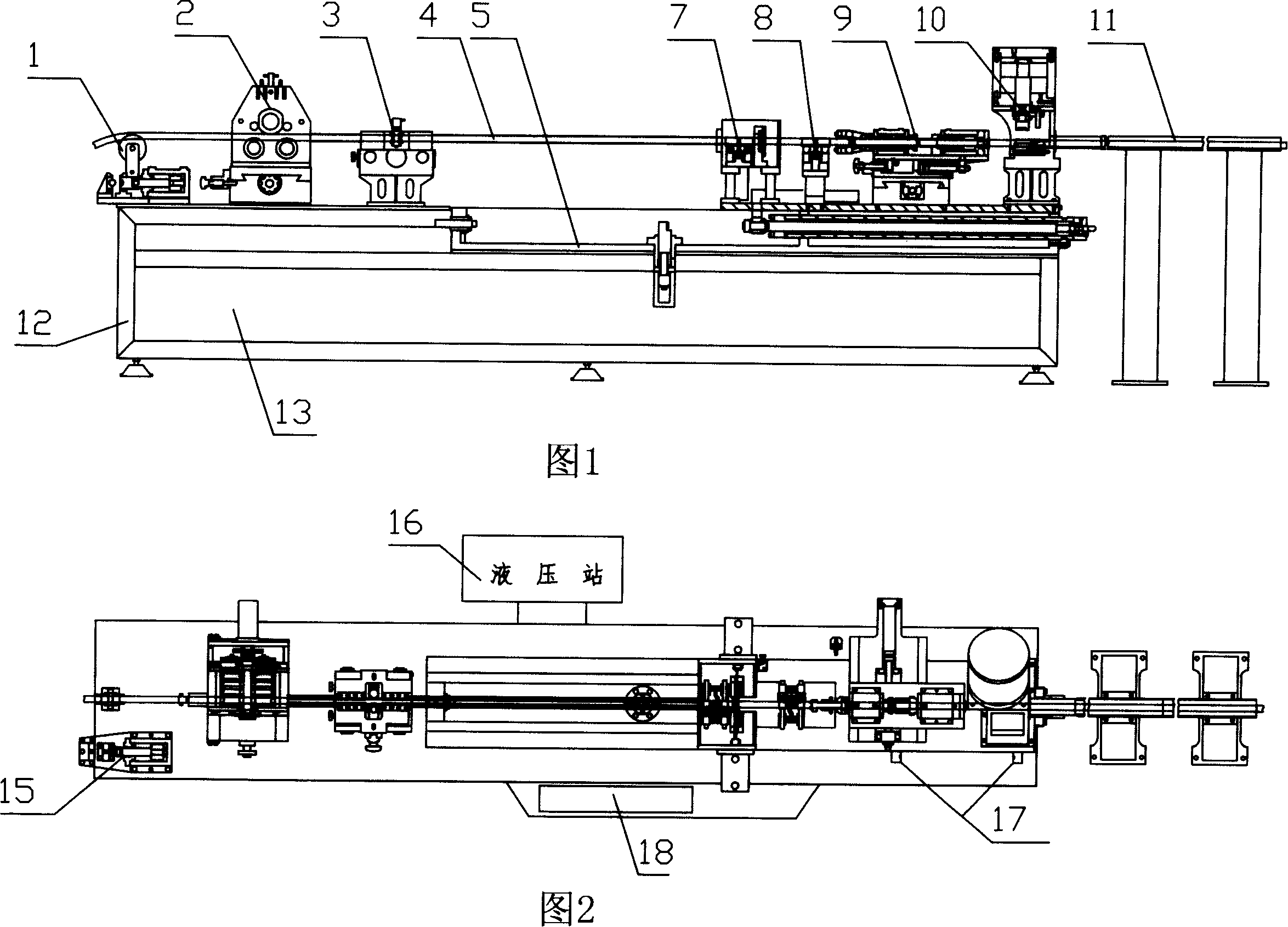

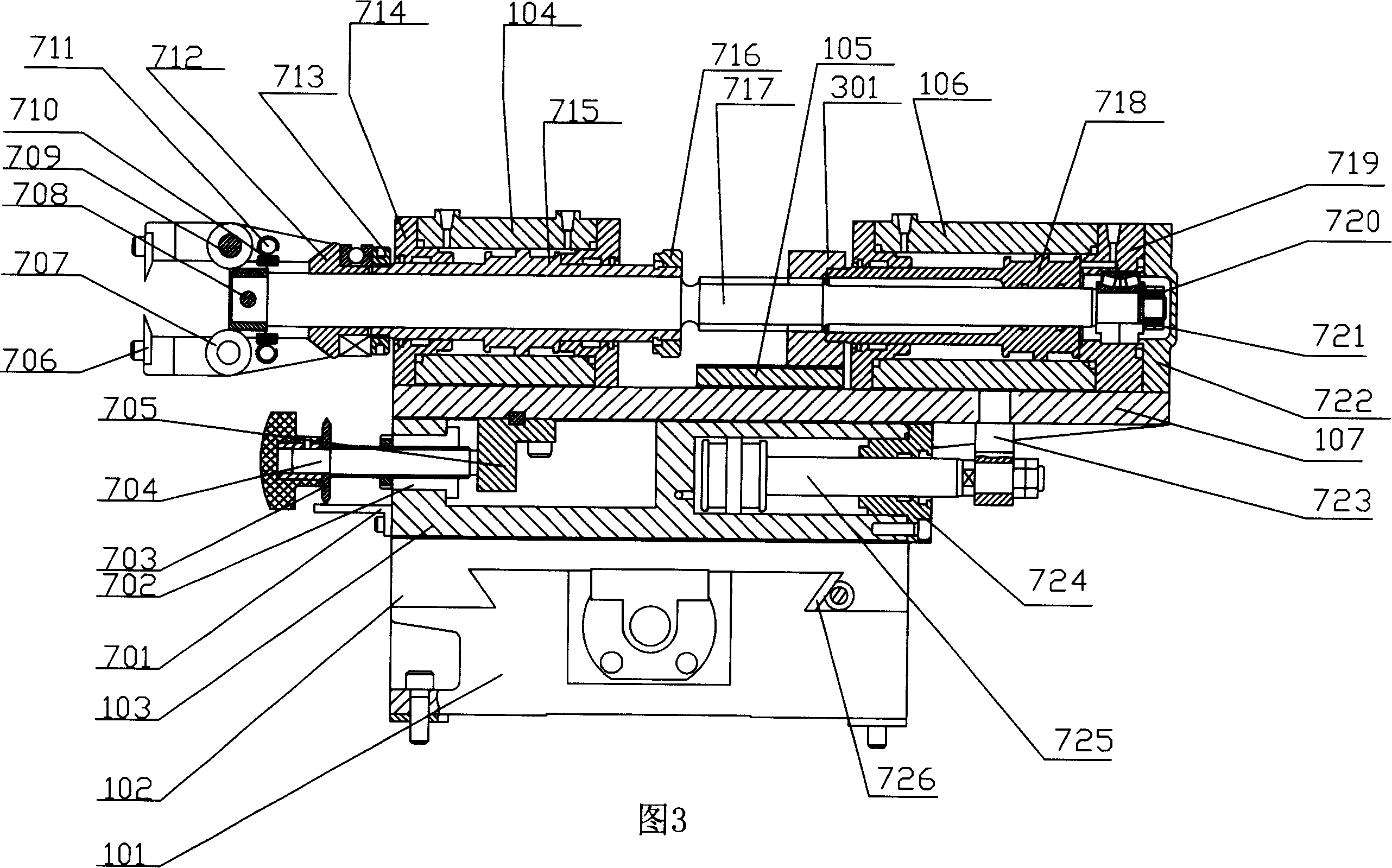

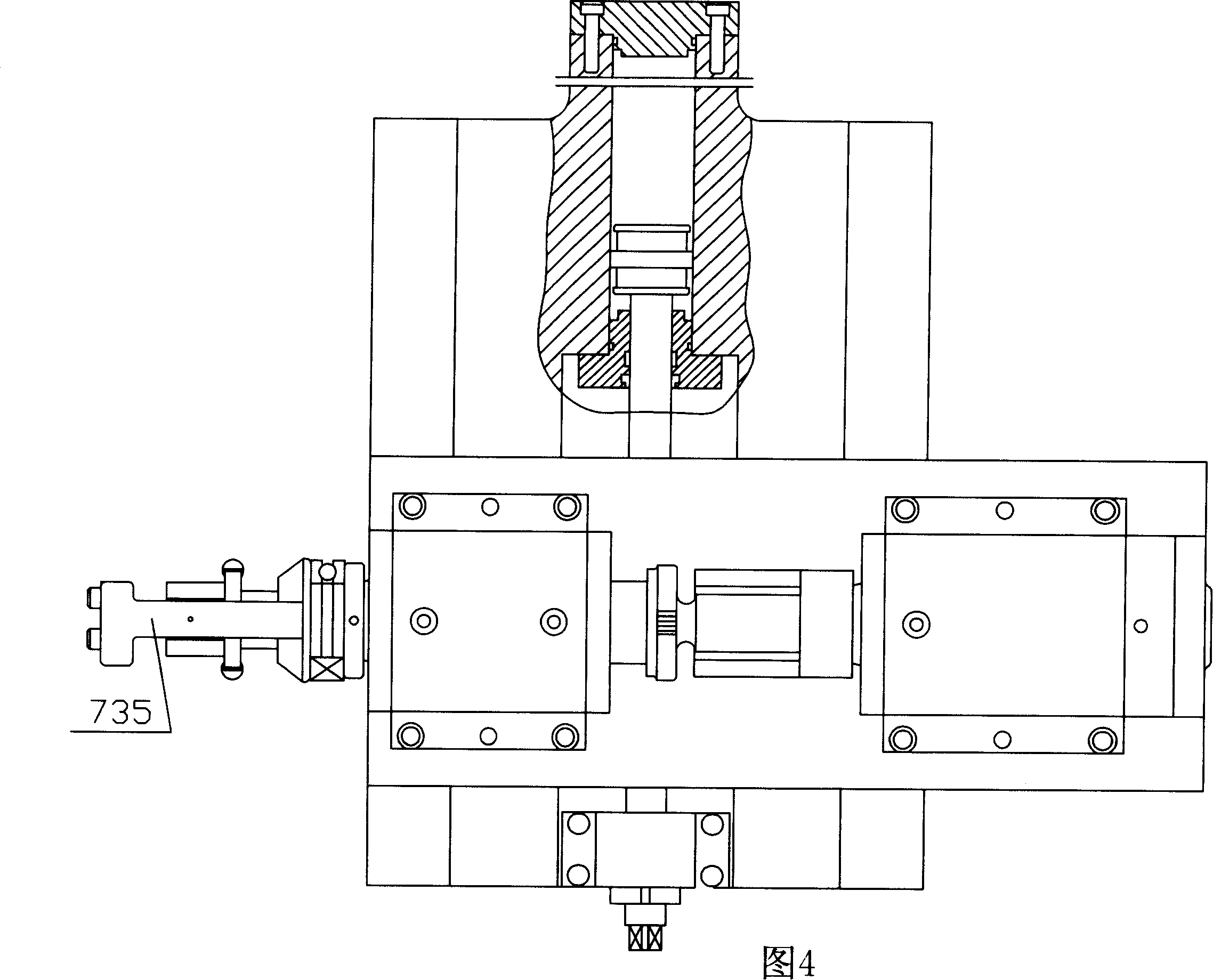

[0027] The cable industrial control off-line machine of the present invention will be described in more detail below in conjunction with specific embodiments with reference to the accompanying drawings.

[0028] The cable industrial control off-line machine includes electromechanical hydraulic joint control part, cable length detection part, pressure monitoring part, rotary peeling part, transmission part and management software part. The offline machine control system is divided into two parts: manual control and automatic control. The automatic control part uses industrial computer and data acquisition card to realize the control of the actuator. The management mode of separating the database administrator and the operator facilitates the quantitative management of the processed and unprocessed cables by the enterprise, assigning responsibilities and tasks to individuals. It not only realizes the manual control of each action of the offline machine through the mouse on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com