Bridge trackway longitudinal spacer assembly

A longitudinal isolation and track technology, applied in the direction of bridges, bridge construction, bridge parts, etc., can solve the problems of increasing maintenance work, bending deformation of the tip of the temperature regulator, and increasing costs, so as to reduce daily maintenance work and reduce engineering costs. The effect of cost and structure size optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

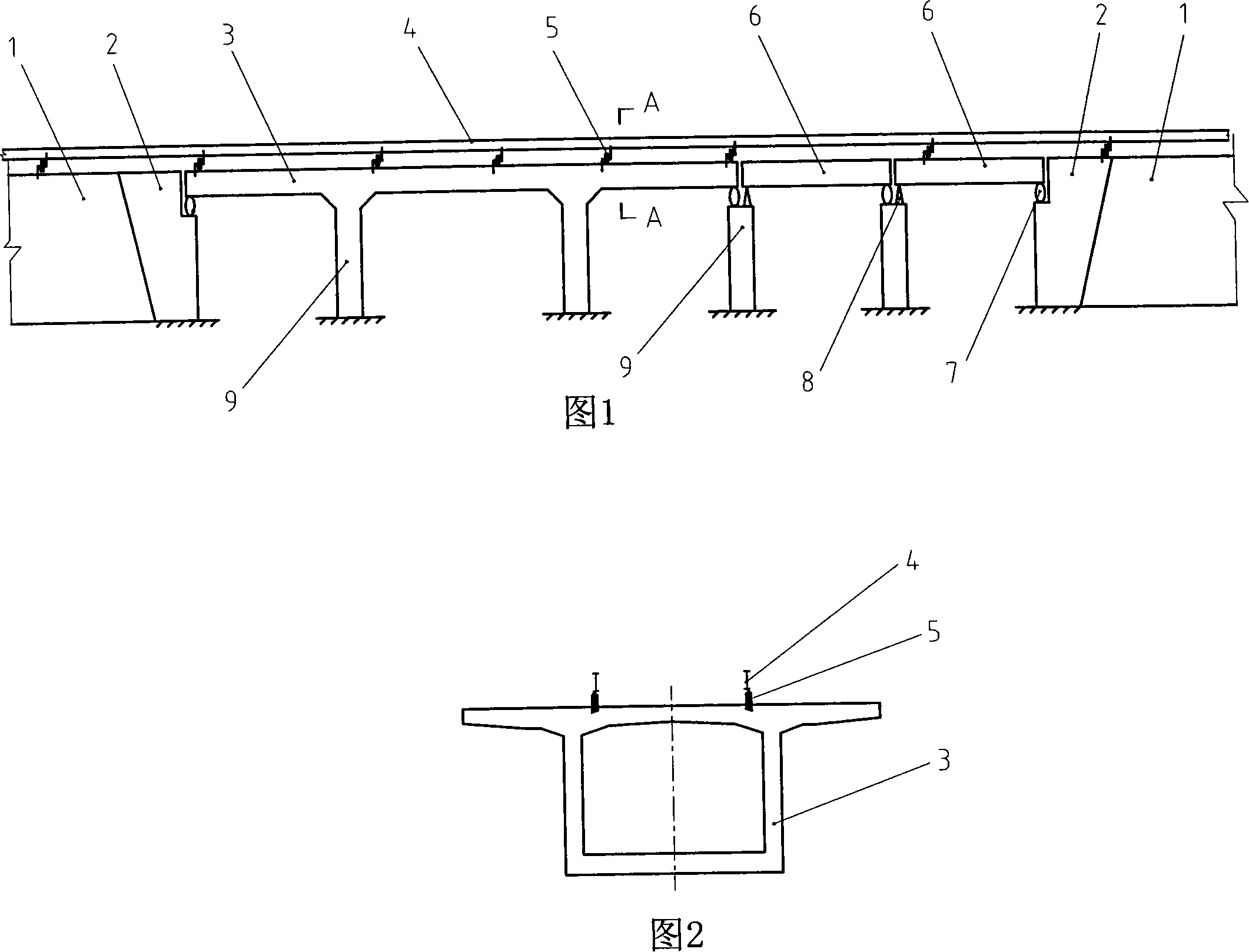

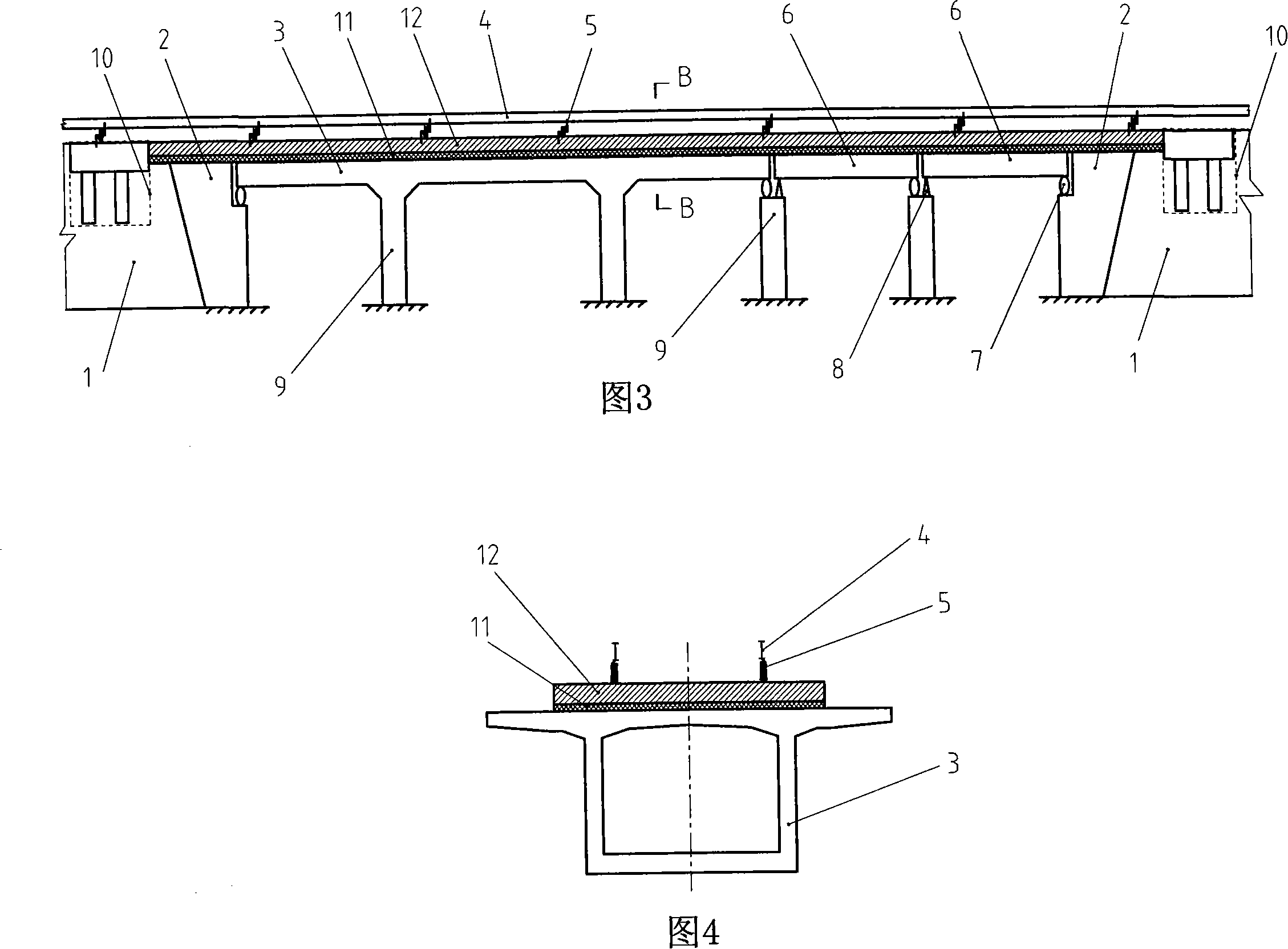

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

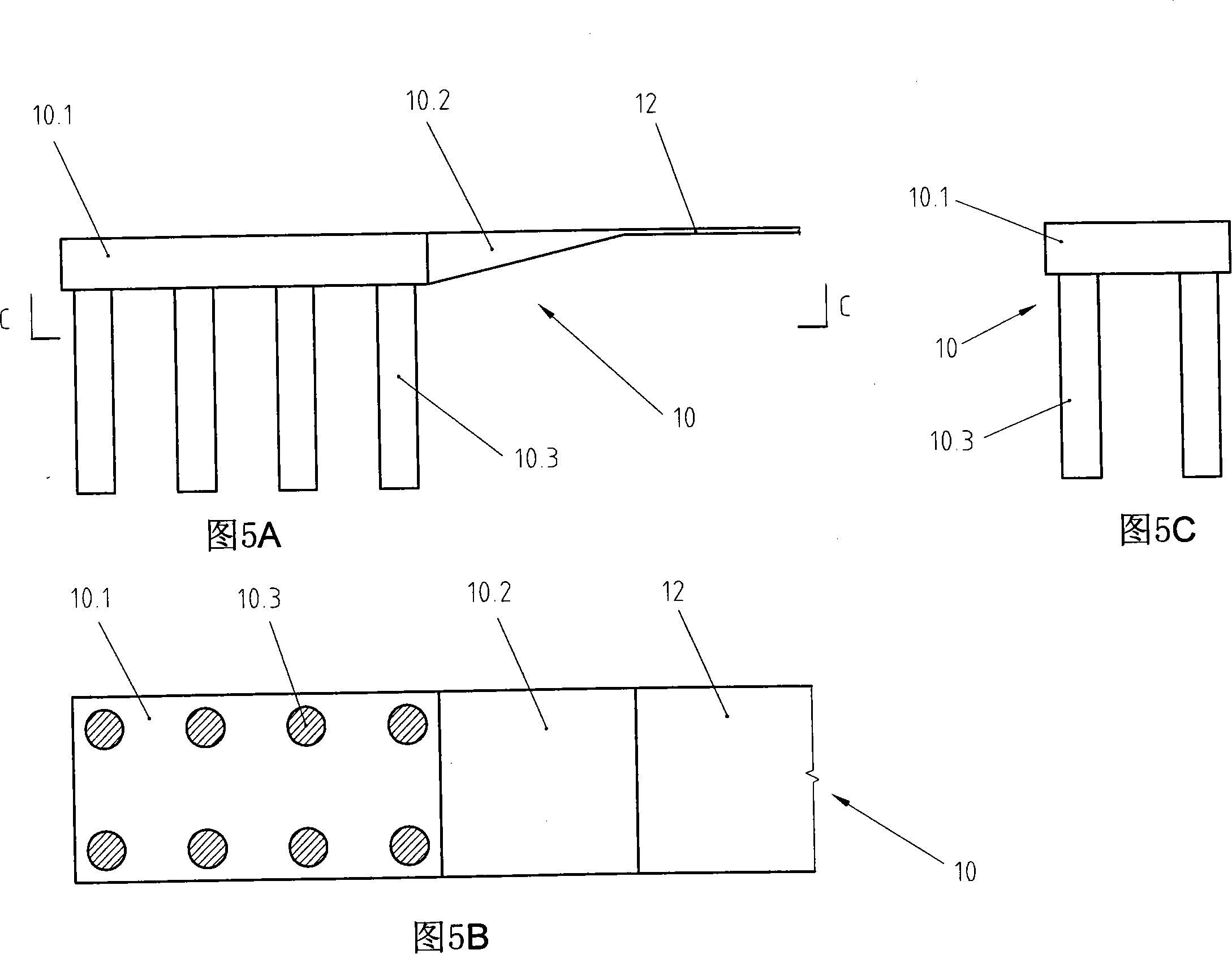

[0018] A bridge track longitudinal isolation device as shown in Figure 3 and Figure 4, includes a longitudinal isolation plate 12, a sliding layer 11, and a limiting platform arranged outside the abutment 2, which are sequentially arranged between the rail 4 and the bridge 10. The longitudinal isolation plate 12 and the sliding layer 11 are all arranged along the length direction of the bridge, and the ends of the longitudinal isolation plate 12 and the sliding layer 11 cross the abutment and extend toward the limit seat 10. In order to increase the transmission effect of the longitudinal force, the longitudinal isolation The plate 12 is rigidly connected with the limit stand 10 . The longitudinal separation plate 12 and the sliding layer 11 are equal in width and greater than the width of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com