Improved ceramic slab for facings, and method for its manufacture

A technology of ceramic plate and ceramic powder, applied in the field of ceramic plate or ceramic tile, can solve the problems of lack of reliability of bonding connection, high cost, and limitation of wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

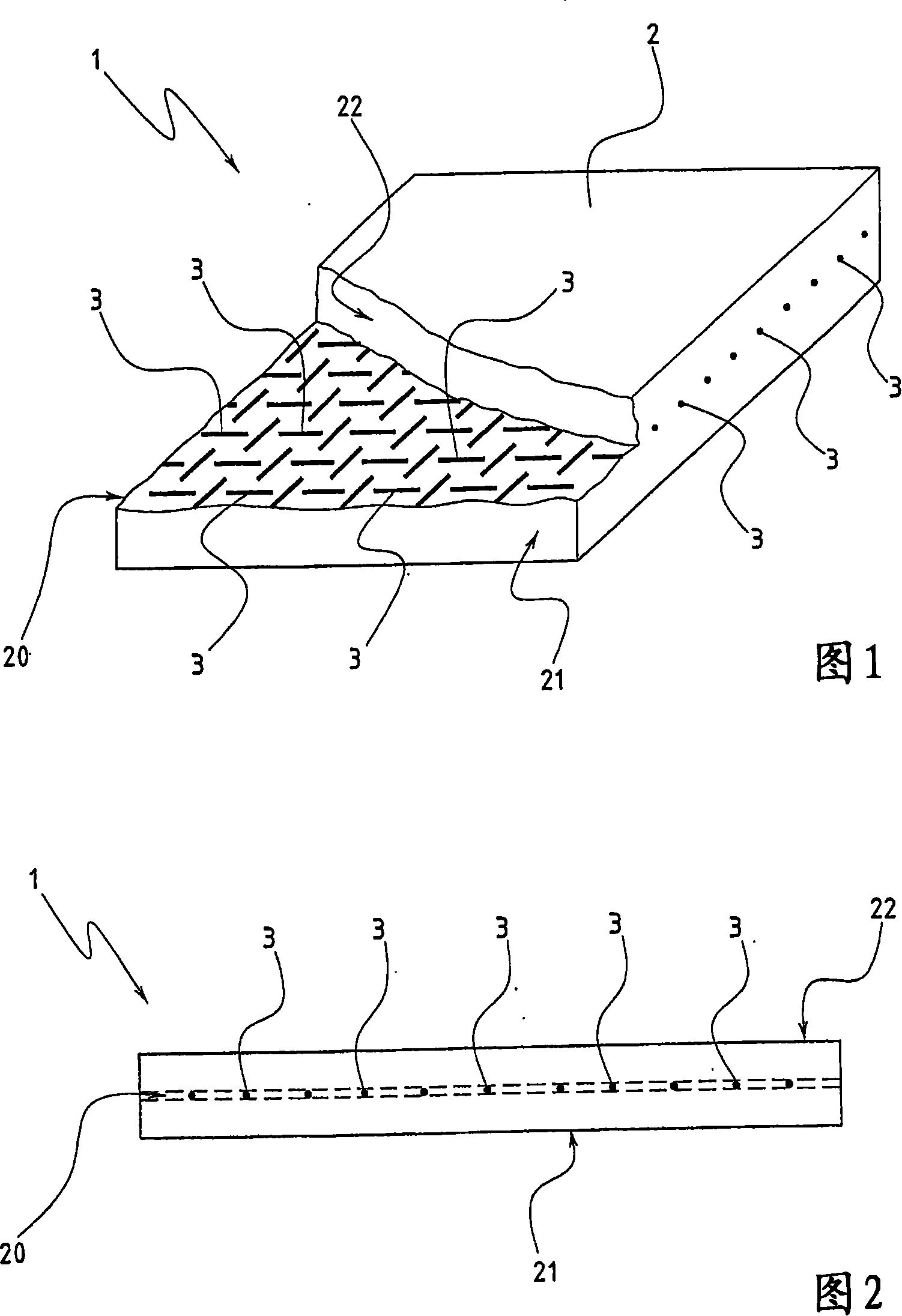

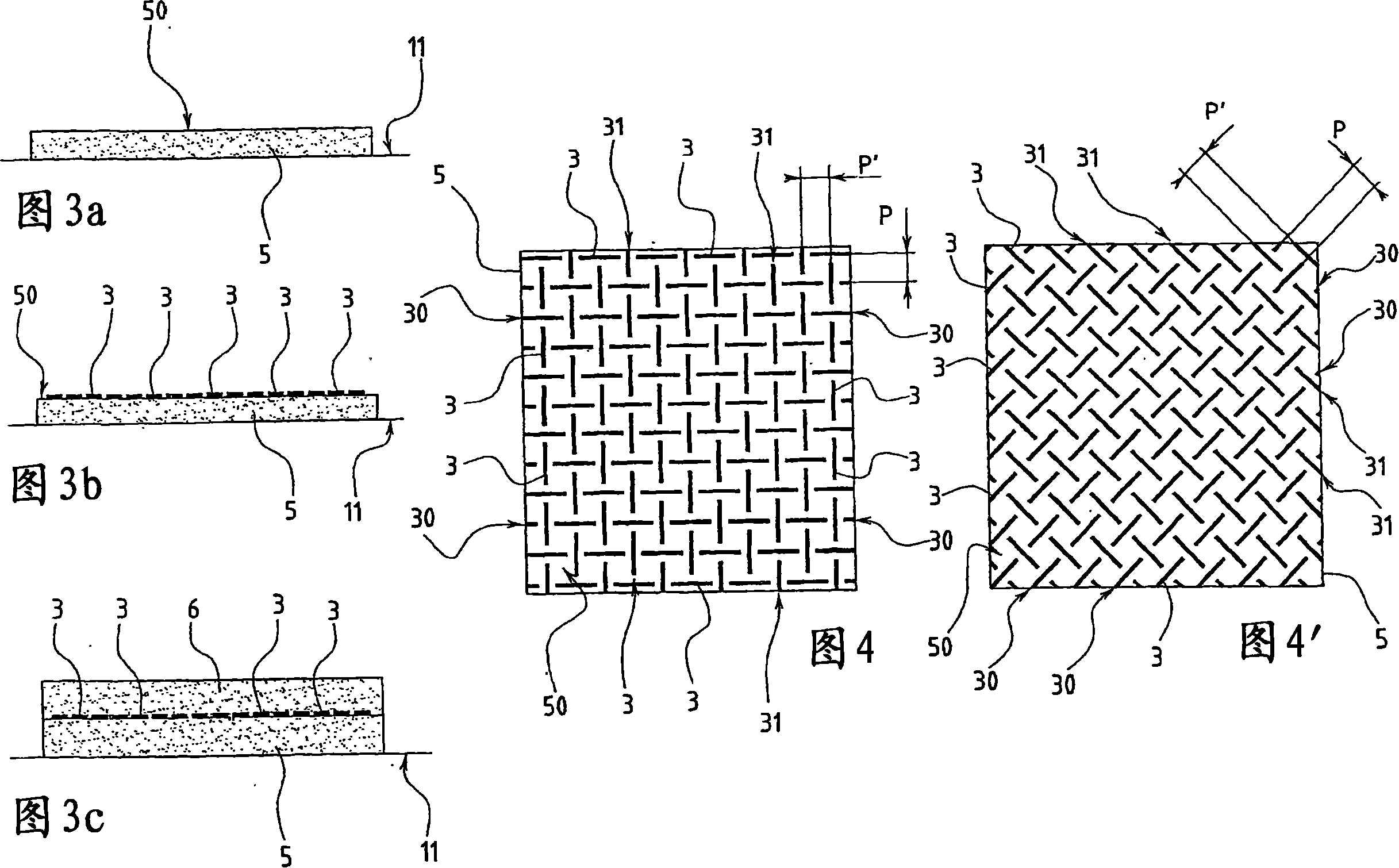

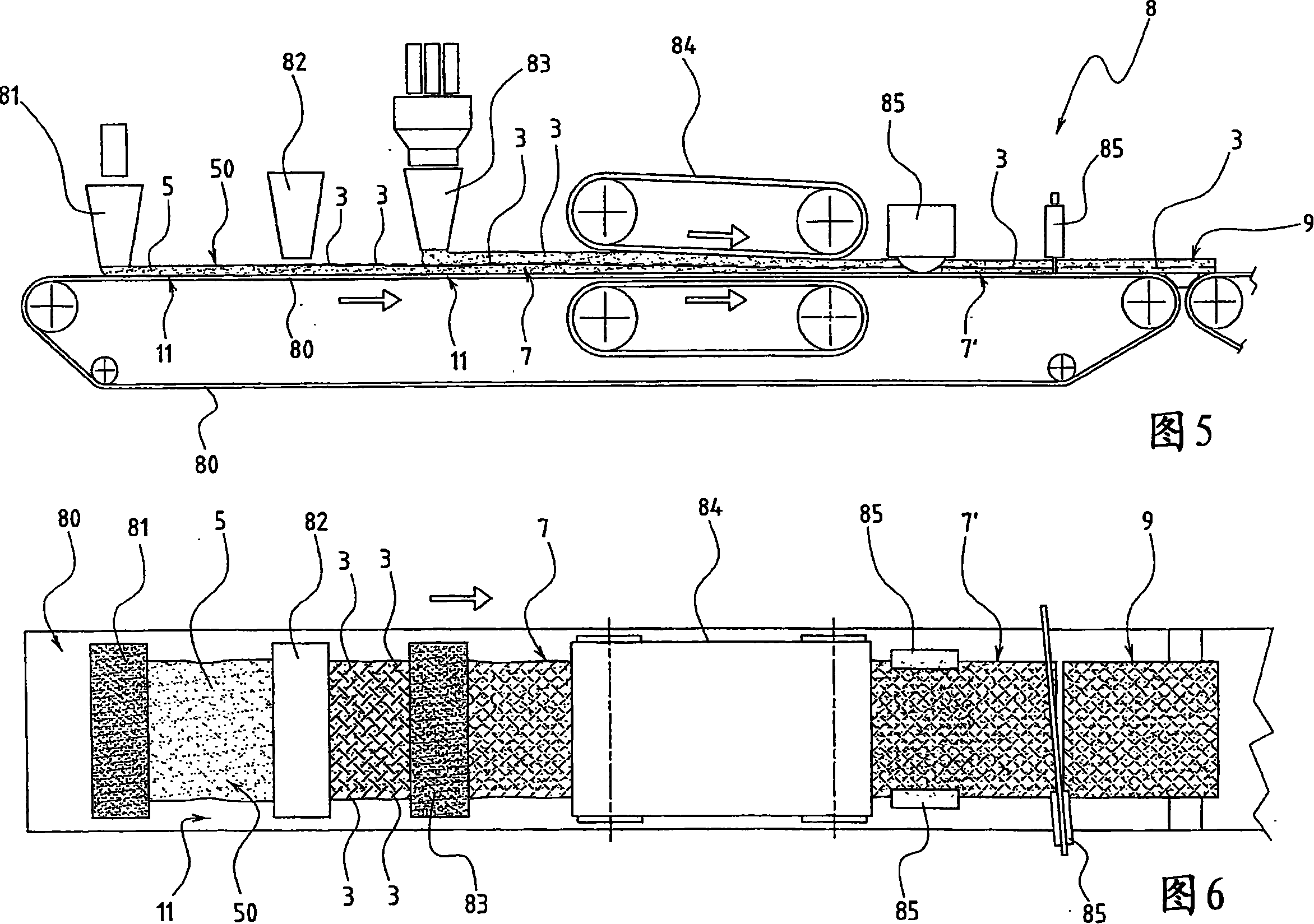

[0053] A reinforced ceramic plate 1, as shown in Figure 1, comprises a continuous ceramic matrix 2 into which reinforcing fibers 3 are incorporated. In the particularly illustrated example, the reinforcing fiber is a steel wire of a straight section, preferably stainless steel; but in general, the reinforcing fiber can be a material such as carbon fiber, glass fiber or aramid fiber that is superior in resistance to the ceramic matrix 2 The filaments are not necessarily straight.

[0054] As shown in FIG. 1 , reinforcing fibers 3 are distributed inside the ceramic matrix, thereby defining a composite layer 20 of ceramics and fibers between two pure ceramic layers 22 and 21 (see also FIG. 2 ), in which composite In layer 20, the reinforcing fibers 3 are located substantially on the same surface, separated and spaced so as to form a discontinuous web.

[0055] In this way, whenever a crack forms in the ceramic plate 1, its propagation is interrupted upon encountering the reinfor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap