Disposable powder point coating nonwoven shoe cover material and its manufacturing method

A technology of powder dot coating and manufacturing method, which is applied in the direction of footwear, shoemaking machinery, clothing, etc., can solve the problems of inability to realize controllable fixed-point coating, achieve short time consumption, improve use function, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

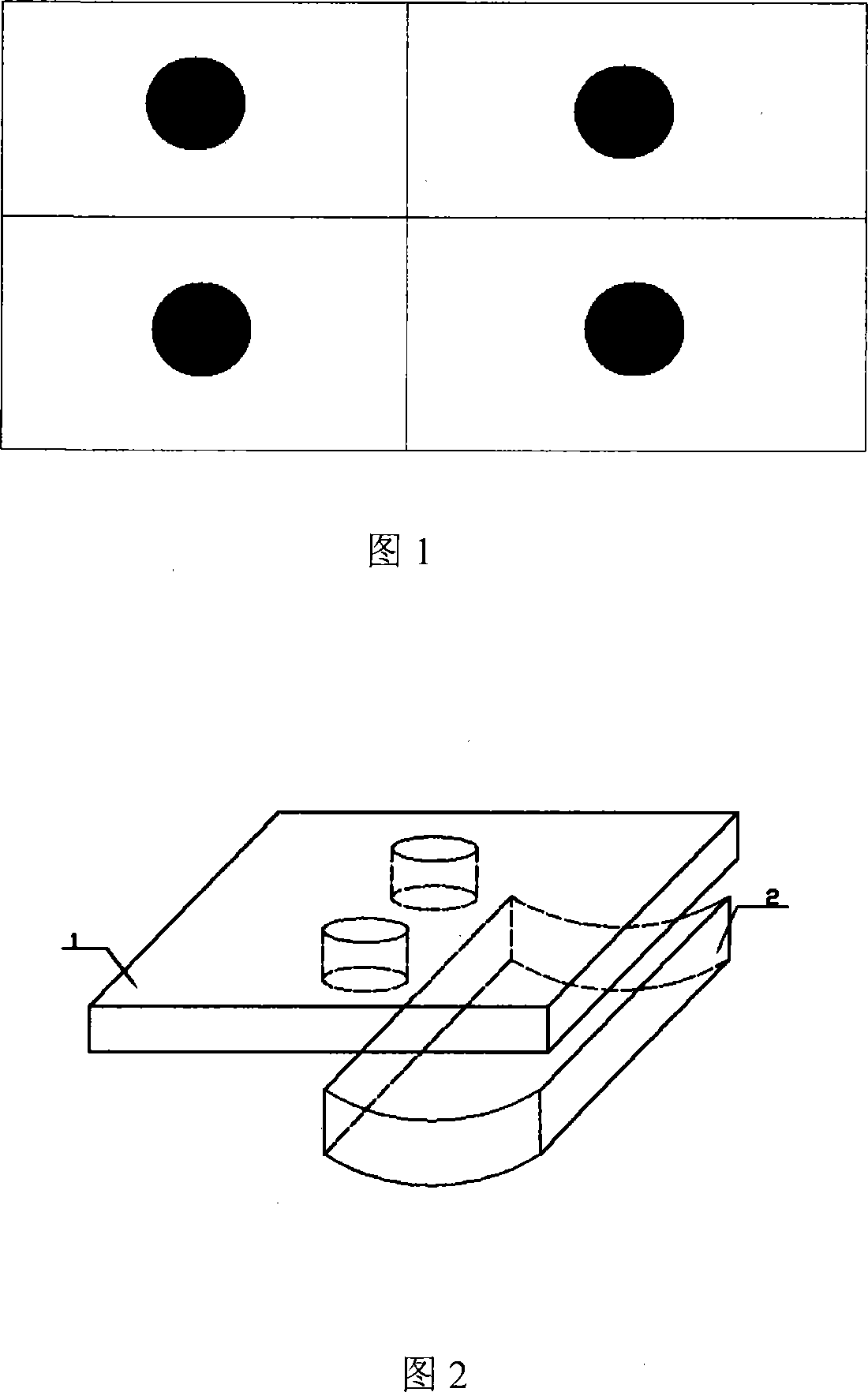

[0030] Accompanying drawing 1 is the structural schematic diagram of powder-spot coated disposable non-woven shoe cover material, the shaded part is the sole material, which is composed of a layer of powder-spot coating and a layer of non-woven fabric, which is a powder adhesive that passes through a duster. The powder dots are formed on the non-woven fabric and obtained after heating and setting, which can be circular, oval, or other irregular shapes required by the sole; the rest is non-woven fabric. The composite material is cut along the dotted line in the figure, and then a rubber band is sewn around to make a disposable non-woven shoe cover with a powder-dot-coated sole.

Embodiment 2

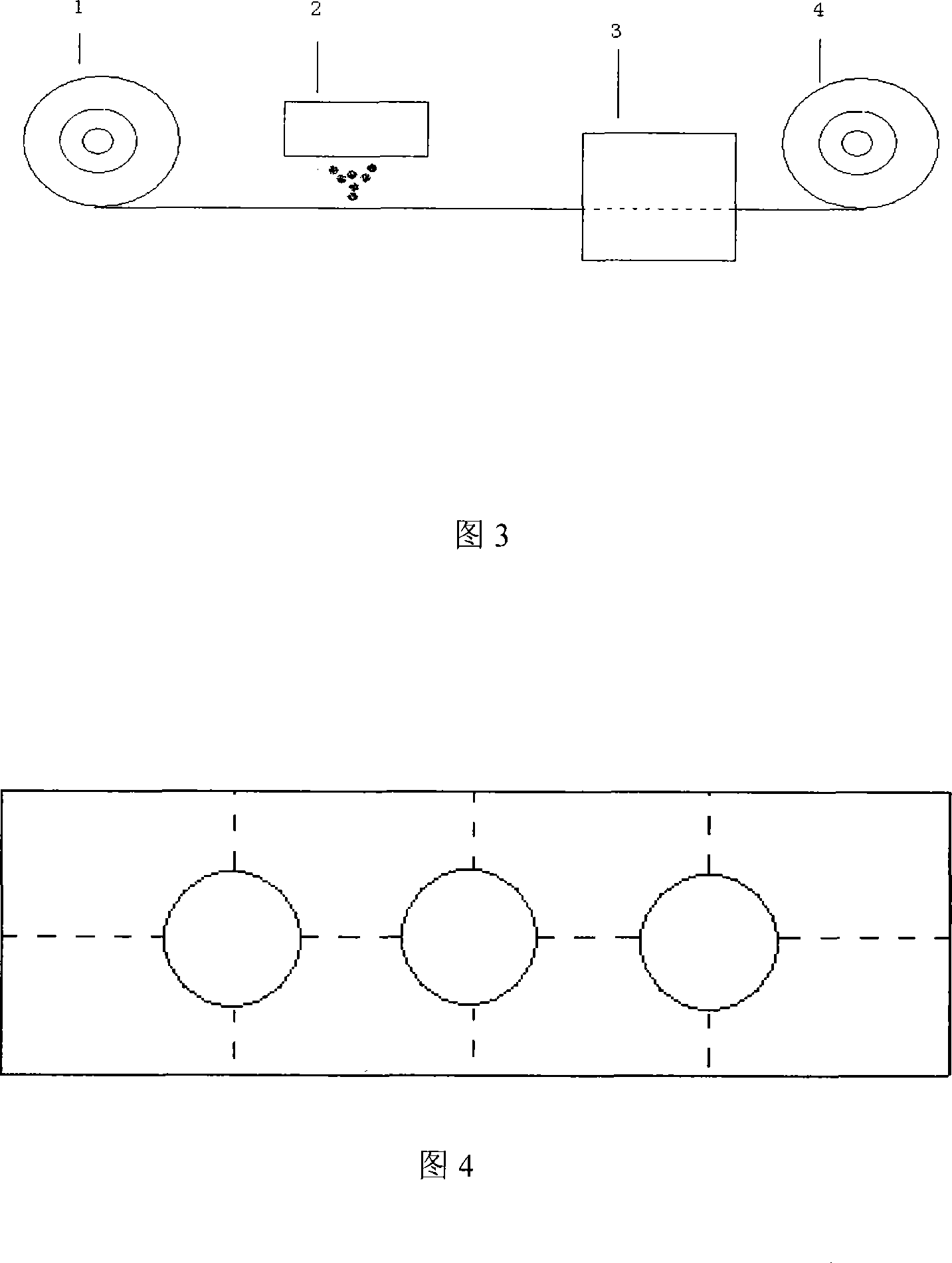

[0032] The width is 0.5m and the areal density is 25g / m 2 The polyethylene spunbond non-woven fabric was unwound at a speed of 100m / min and entered the duster. A controllable fixed-point duster with a vibrating screen radius of 0.1m was used, and low-density polyethylene powder was used as a binder. The residence and departure times of the receiving plate under the screen holes were 0.3 seconds and 0.12 seconds, respectively. The powder binder forms approximately circular powder dots with a spacing of 0.5 m on the longitudinal centerline of the nonwoven fabric. The above-mentioned non-woven fabric continues to enter an oven with a temperature of 95 ° C at a speed of 100 m / min, heat and shape, and coil to obtain a width of 0.5 m, a powder coating radius of 0.1 m, and the center of the coating is 0.25 m away from the edge of the non-woven fabric. The powder-dot-coated disposable non-woven shoe cover material with a spacing of 0.5m is shown in Figure 4 for the structure.

Embodiment 3

[0034] The width is 0.5m and the areal density is 25g / m 2 The polypropylene spunbond nonwoven was unwound at a speed of 5m / min into the duster. A controllable fixed-point duster with a vibrating screen radius of 0.1m was used, and low-density polyethylene powder was used as a binder. The residence and departure times of the receiving plate under the screen holes were 6 seconds and 2.4 seconds, respectively. The powder binder forms approximately circular powder dots with a spacing of 0.5 m on the longitudinal centerline of the nonwoven fabric. The above-mentioned non-woven fabric continues to enter the oven with a temperature of 95 ℃ at a speed of 5m / min, heat-setting, and coiling to obtain a width of 0.5m, a powder coating radius of 0.1m, and the center of the coating is 0.25m away from the edge of the non-woven fabric. Powder-dot-coated disposable non-woven shoe cover material with a pitch of 0.5m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com