Single aperture tube liquid-liquid multi-chamber transfusion soft bag and its production method

A technology for infusion soft bags and mouth tubes, which is applied in the field of medical infusion containers and storage of infusion preparations. It can solve the problems of complex structure and production process, limited mixing port cross-section, and large number of mouth tubes, so as to save membrane materials and reduce product cost. Cost, the effect of reducing the number of orifice tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

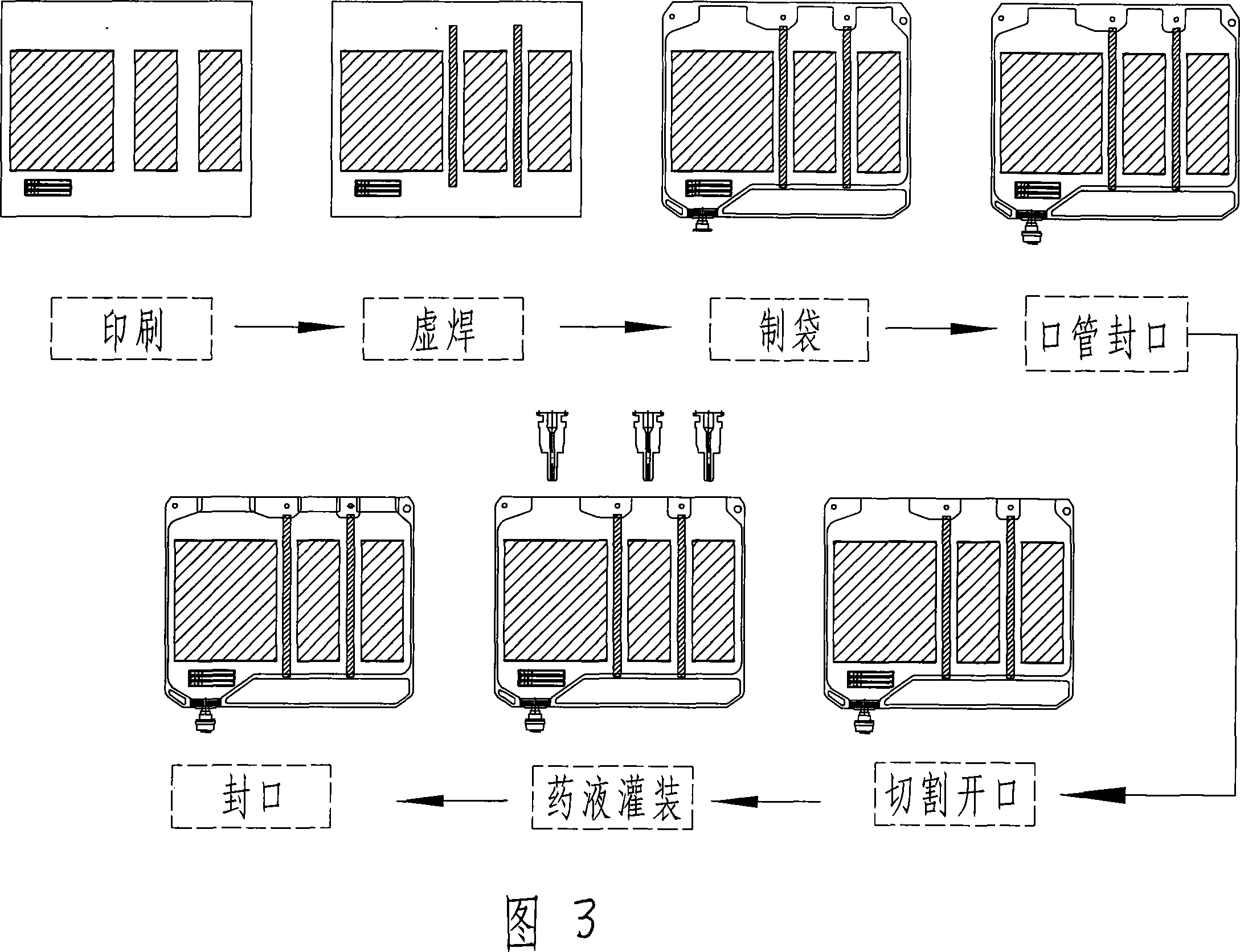

[0023] The present invention will be further described below in conjunction with the accompanying drawings of the embodiments.

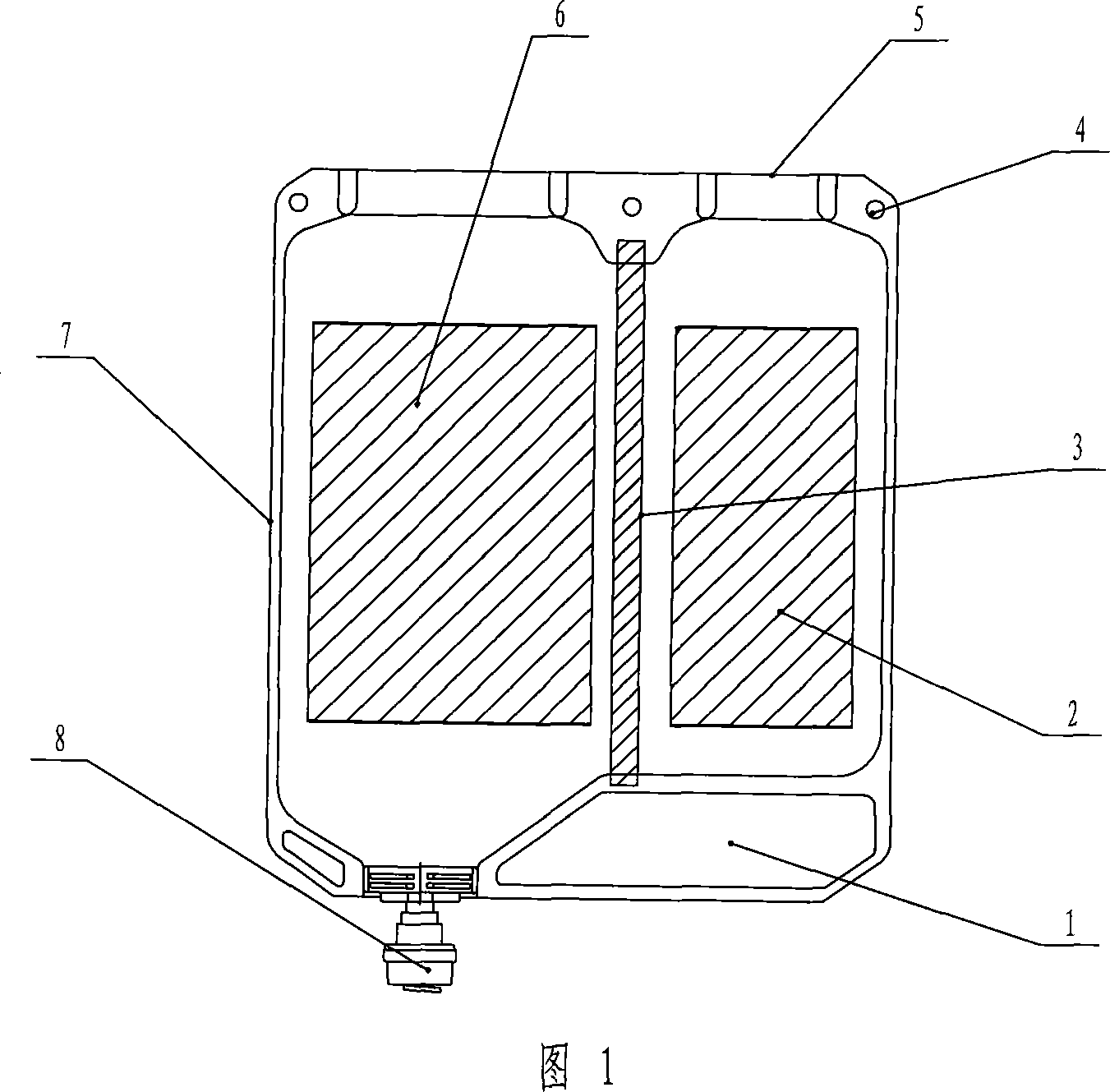

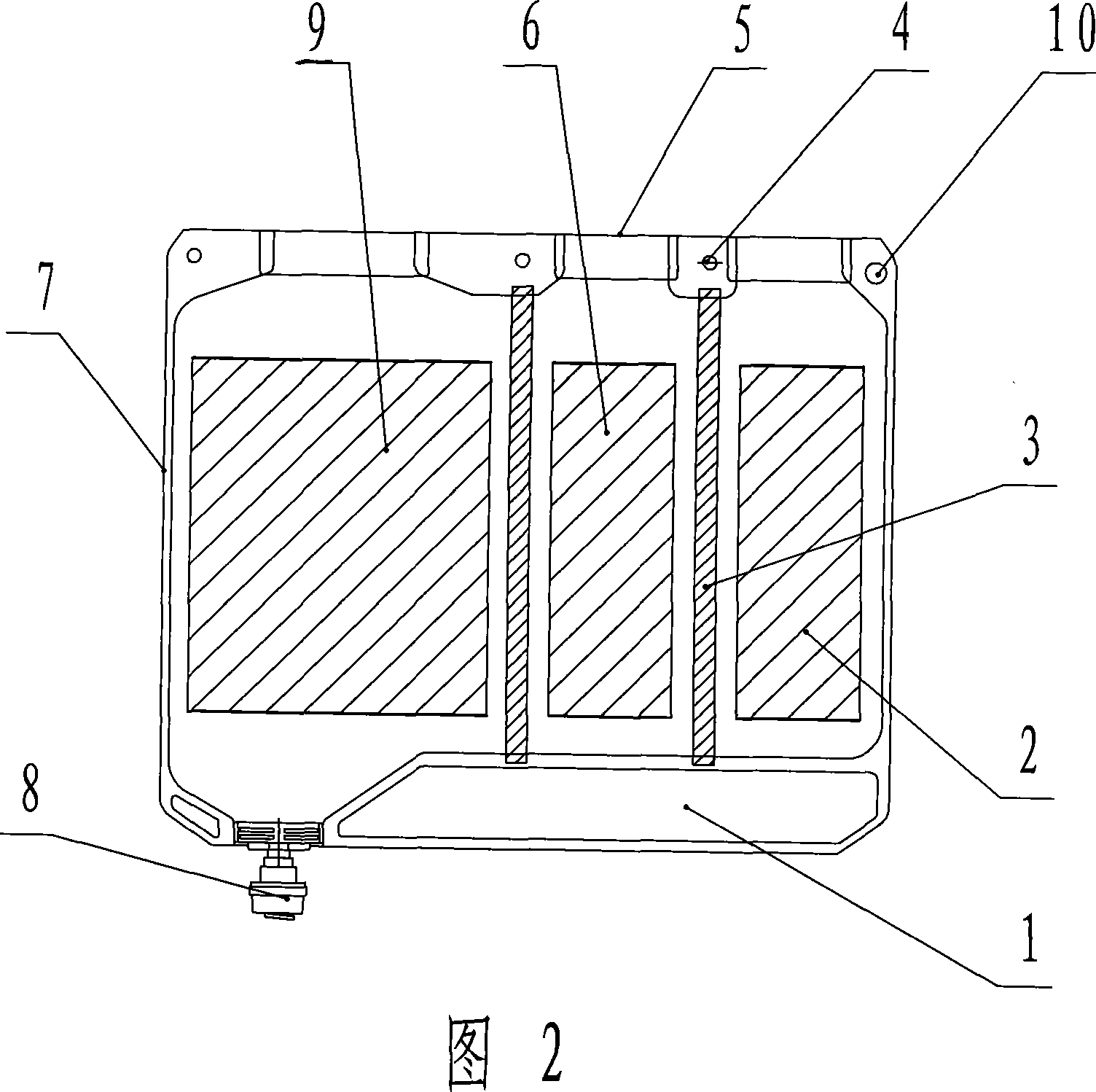

[0024] As shown in Figure 1, what the present invention describes is a soft bag for transfusion with two chambers (also known as double chambers) of a single oral tube, the sealed bag body is formed by welding the periphery of two bag films, and the bag body is provided with two dissolving liquids. Chambers 2 and 6, two dissolving solution chambers 2 and 6 are arranged horizontally, and two adjacent chambers 2 and 6 are separated by a virtual weld 3, and a group of mouth tubes are fixedly connected to one of the dissolving solution chambers 6 8. On the end of the sealed bag body 1 opposite to the mouth tube 8, at least two positioning holes 4 are provided, corresponding to each solution chamber, a corresponding liquid filling port is set at the bottom edge 5 of the bag body, and the mouth tube 8 It is a hard mouth pipe, and the mouth pipe 8 has a med...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap