Filtering board

A filter plate, integrated technology, applied in the direction of filtration separation, loose filter material filter, gravity filter, etc., can solve problems such as insufficient water and gas distribution uniformity, uneven water and gas distribution, and inability to reverse filtration, etc. To achieve the effect of small occupied space, simple structure, not easy to leak sand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

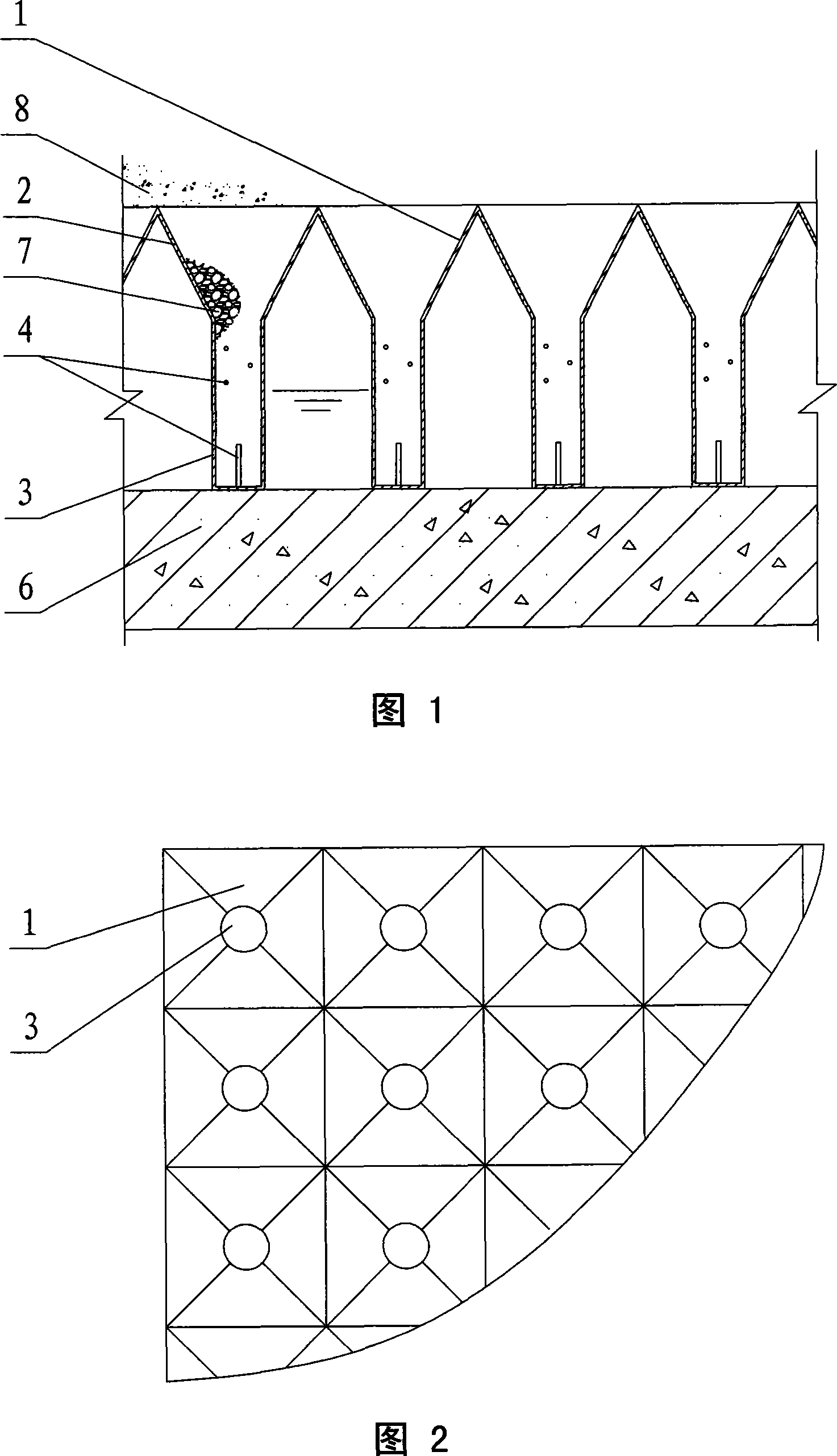

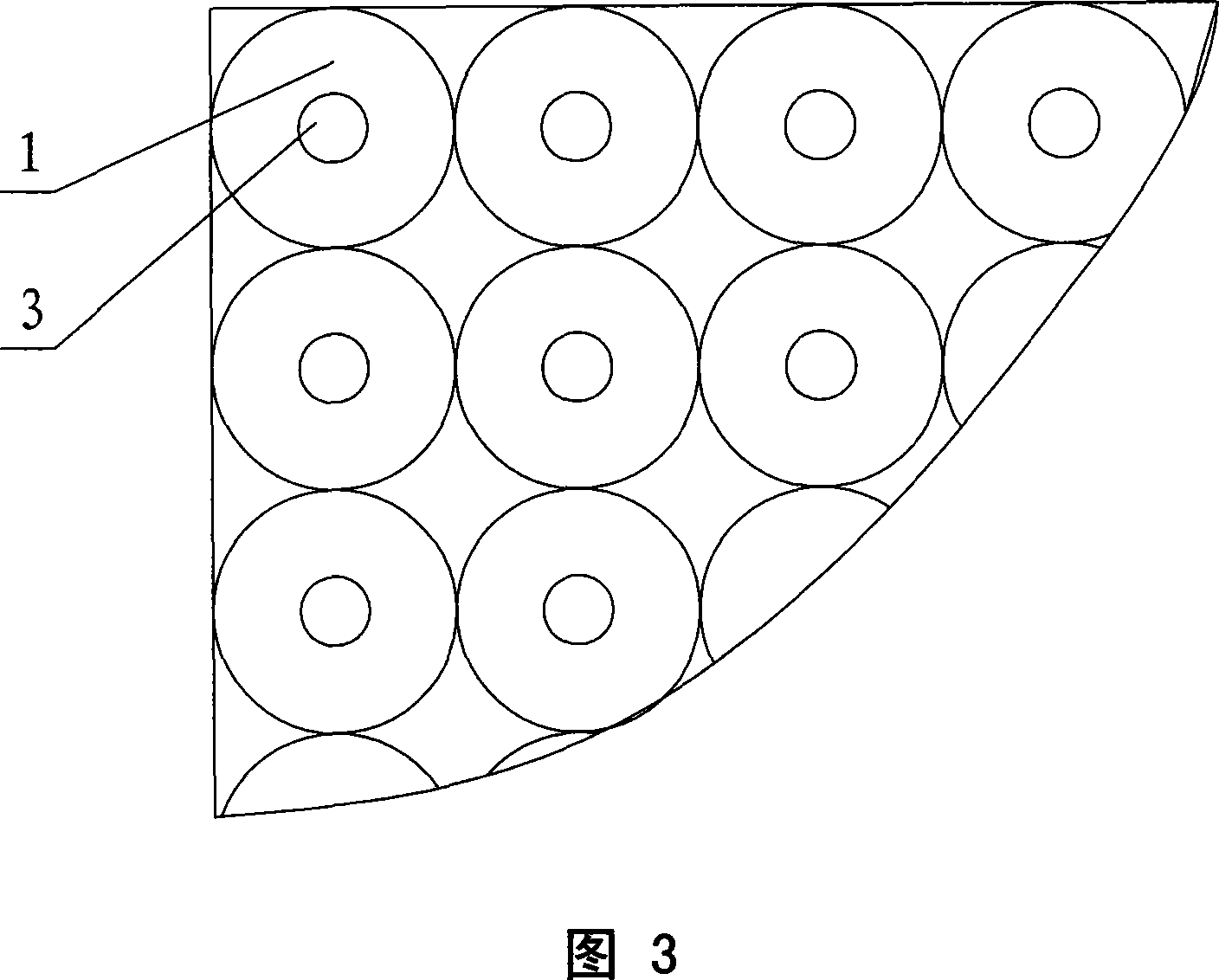

[0015] As shown in Fig. 1 and Fig. 2, the present invention comprises several funnel bodies 1, and described funnel body 1 comprises the bucket part 2 that is arranged on the top and the conduit part 3 that is arranged on the bottom, the lower end of bucket part 2 and conduit part 3 The upper ends are connected, the bucket portion 2 is a circular body above and below, and several funnel bodies 1 extend outward along the upper wall of the bucket portion 2 and are connected into one body. The pipe wall of the conduit portion 3 is provided with A number of water distribution and air distribution holes 4, the water distribution and air distribution holes 4 in the upper part are round holes, the water distribution and air distribution holes 4 in the lower part are elongated holes, and the bottom of the conduit part 3 is closed. Of course, the water distribution and air distribution holes 4 can also use other layout.

[0016] Since the present invention is composed of several identi...

Embodiment 2

[0019] As shown in Fig. 1 and Fig. 3, the cross section of the bucket part 2 is circular, and other structures are the same as those in the first embodiment.

Embodiment 3

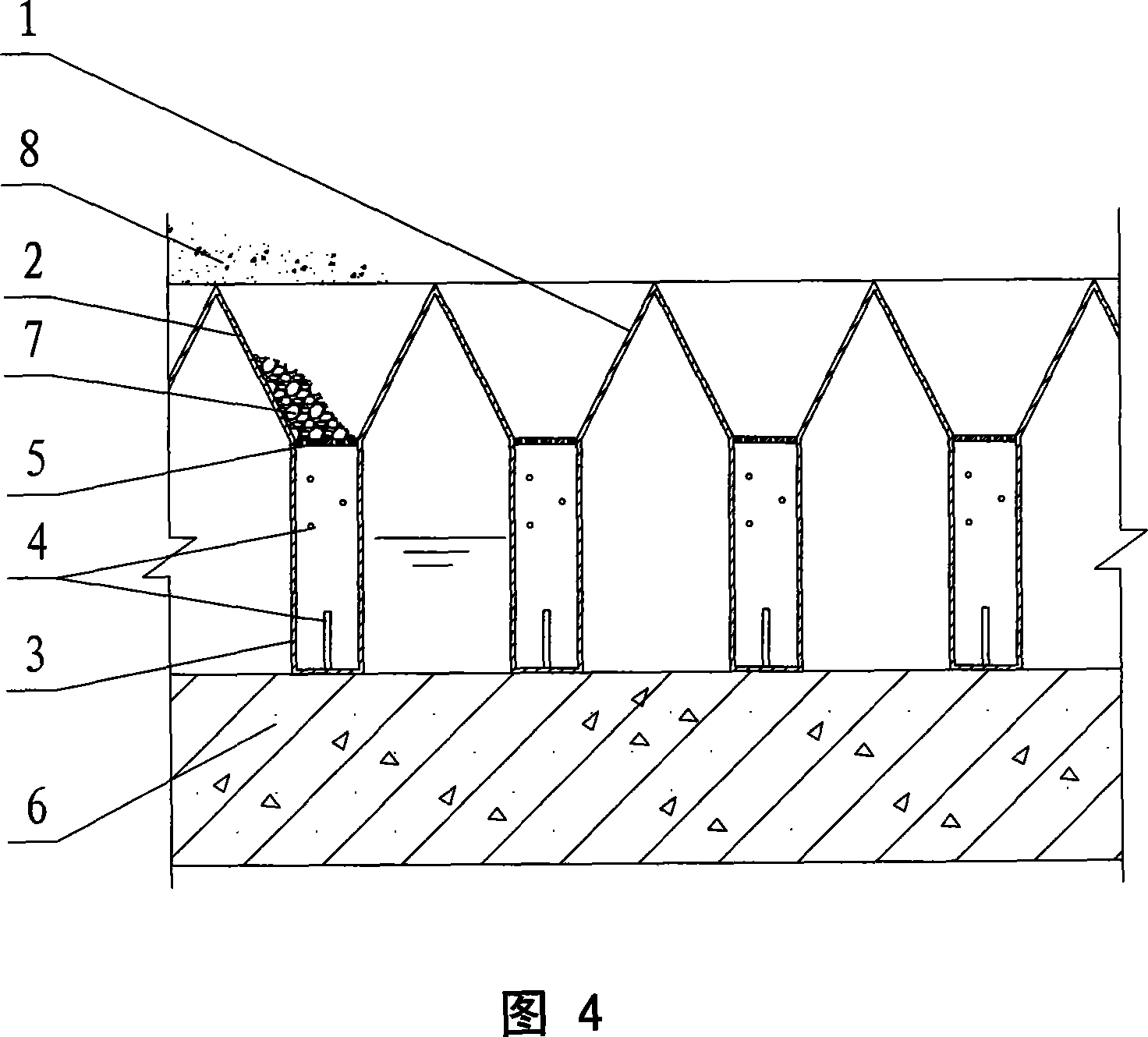

[0021] As shown in FIG. 4 , a grid 5 is arranged at the lower part of the bucket 2 , and a gravel supporting layer 7 is arranged on the grid 5 , and other structures are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com