Multifunctional cyclone plasma air processing machine

An air handler and cyclone-type technology, which is applied in the field of air purification, can solve problems such as warping and deformation of flat plate electrodes, the air velocity should not be too large, and the normal operation of the plasma generator is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

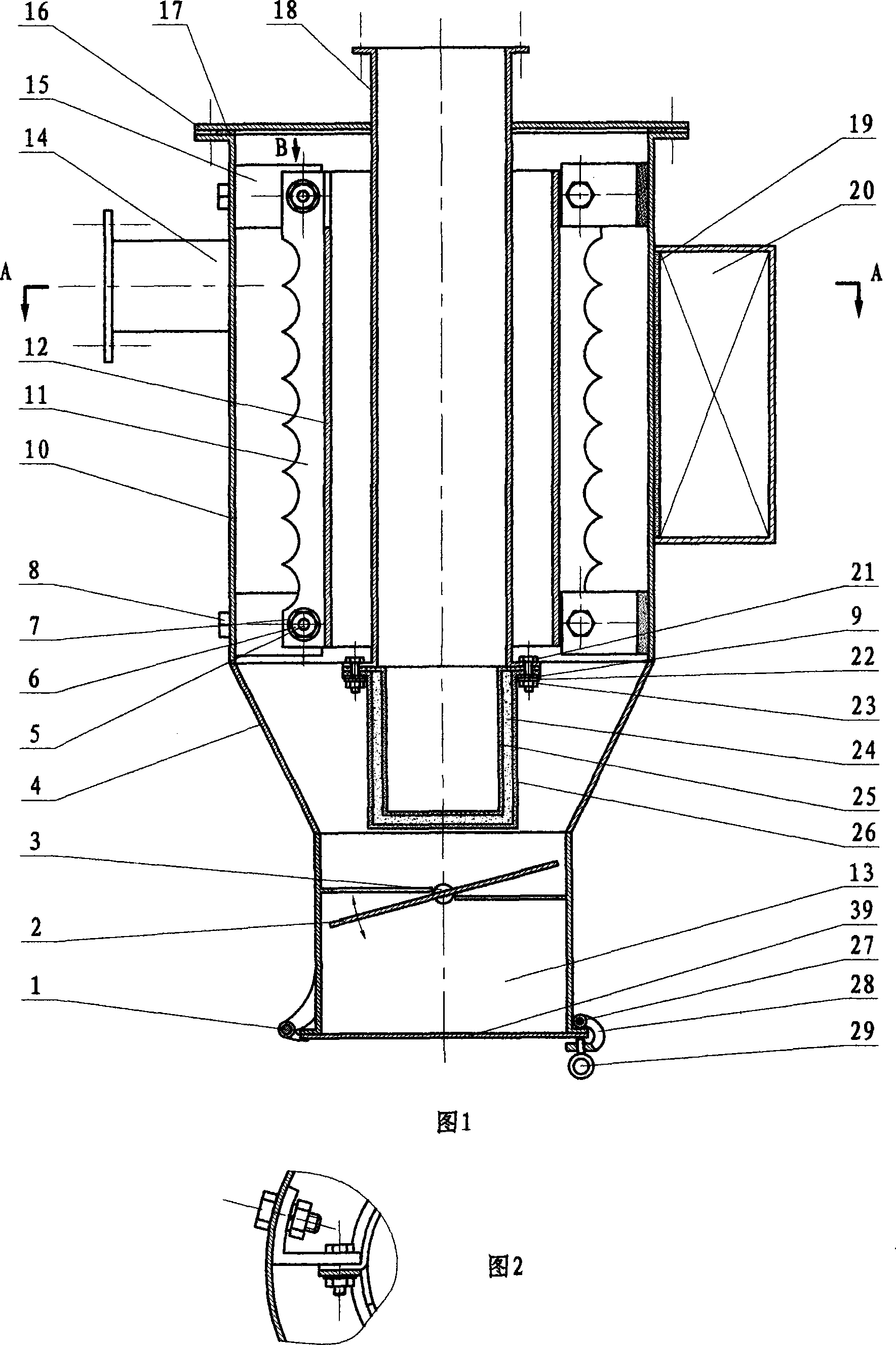

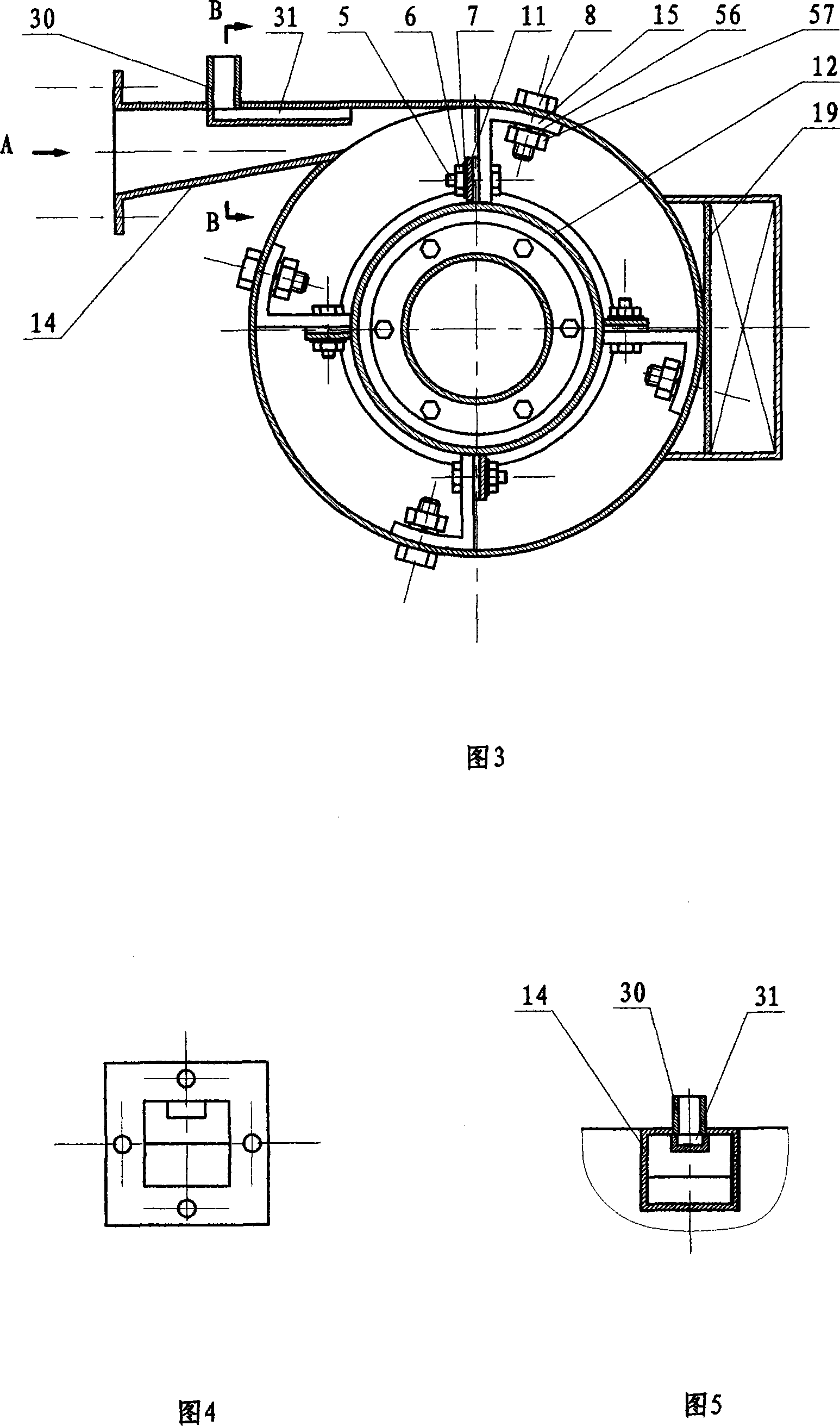

[0047] Embodiment one: in conjunction with Fig. 1, Fig. 2, Fig. 3, Fig. 4 and shown in Fig. 5, the multifunctional cyclone type plasma air processor of the present embodiment, it comprises a cylindrical shell (10), cylindrical shell The upper part of the body (10) is provided with a tangential air intake pipe (14) in the form of a gradual cross section, a vertically installed air outlet pipe (18) is provided in the middle, a dust collection chamber (13) is provided below it, and a top is provided on the top. Cover (16), the outer edge of the top cover (16) is sealed and fixedly connected with the cylindrical housing (10) top by a sealing ring (17) and fasteners, and the inner edge of the top cover (16) is connected with the air outlet pipe ( The outer wall of 18) is fixedly connected by welding and sealing; 4 rack-shaped high-voltage electrodes (11) are arranged circumferentially in the middle of the annular area between the cylindrical shell (10) and the outlet pipe (18). The...

Embodiment 2

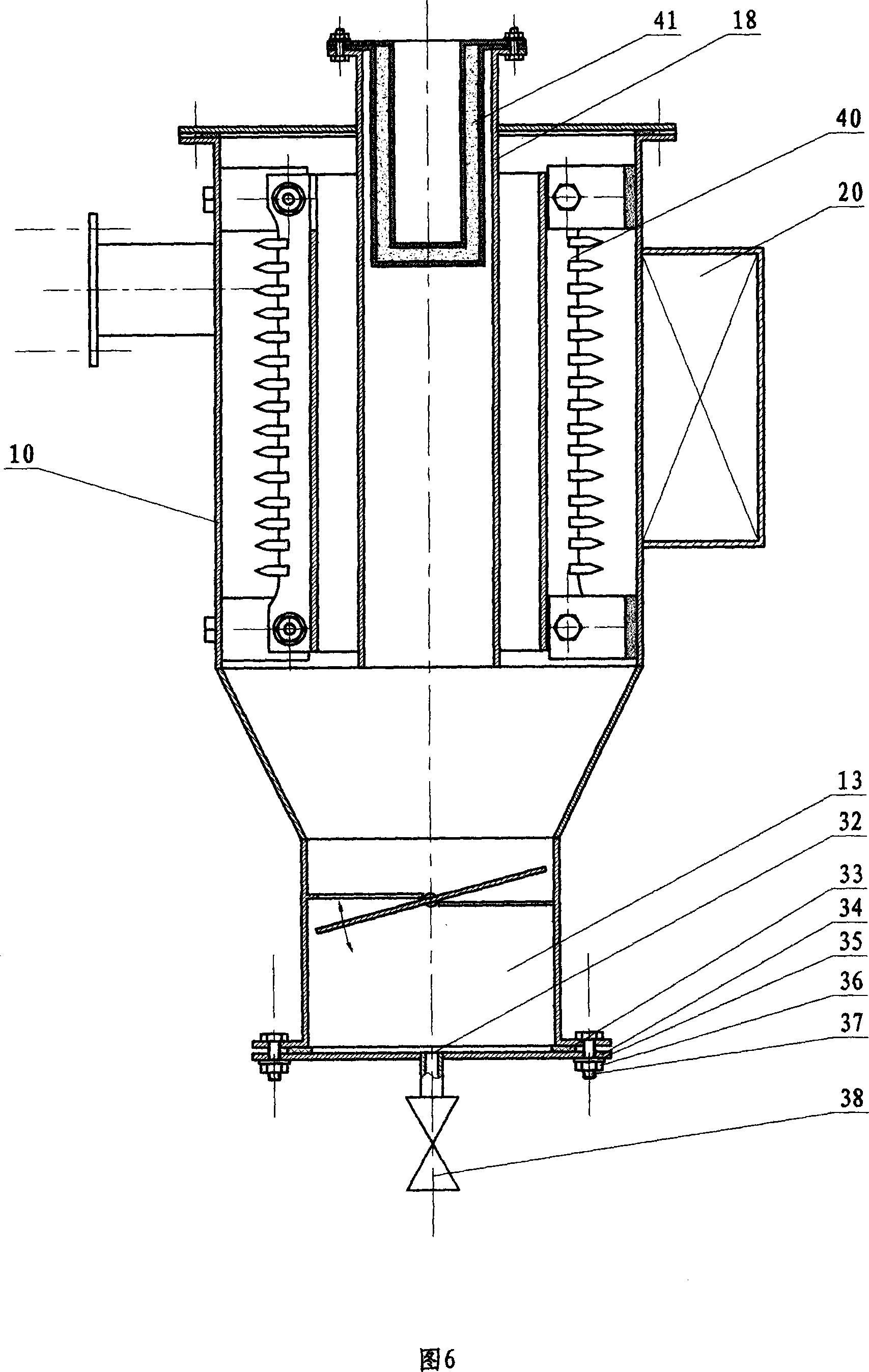

[0050] Embodiment two: in conjunction with shown in Fig. 6, present embodiment multifunctional cyclone type plasma air processor, bottom cover (34) is provided with dust collecting chamber, and bottom cover (34) passes seal ring (33), nut (36), Gasket (35), bolt (37) and the housing of dust collecting chamber (13) are sealed and fixedly connected, and opening (32) is provided on the bottom cover (34), and opening (32) is provided with connecting pipe, and valve ( 38), there is no heat insulating material between the cylindrical casing (10) and the plasma generator power supply (20), and the air post-processing device (41) is arranged on the upper part of the air outlet pipe and adopts fasteners and the air outlet pipe (18 ) are fixedly connected, and four grid strip-shaped high-voltage electrodes (40) are arranged in the middle ring direction of the annular area between the cylindrical shell (10) and the gas outlet pipe (18). Other requirements of this embodiment are the same ...

Embodiment 3

[0051] Embodiment three: in conjunction with Fig. 13, Fig. 14 and shown in Fig. 15, present embodiment is on the basis of embodiment two, and grid-shaped auxiliary high-voltage electrode (44) is set in the middle and lower part in outlet pipe (18), electrode ( 44) the burr tip points to the inner wall of the outlet pipe (18), and the electrode (44) passes through the insulating connector (45), bolt (47), nut (49), washer (48), bolt (50), nut (51 ) and gasket (52) are fixed on the pipe wall of the air outlet pipe (18), and the air guide head (42) is set below the air outlet pipe (18). The ends of the air guiding head (42) and the four ribs (53) extending inwardly from the connecting plate (43) are fixedly connected by welding, and the connecting plate (43) is then fixed to the lower end of the air outlet pipe (18) by fasteners connect. The areas between the individual ribs (53) serve as airflow channels. Other requirements of this embodiment are the same as those of Embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com