Single cylinder dual-action type spot welding machine welding head

A double-acting, spot welding machine technology, used in welding equipment, resistance welding equipment, resistance electrode bases, etc., can solve the problems of welding point quality fluctuation, unadjustable clamping force, workpiece deformation, etc., to achieve stable welding point quality, The effect of low processing cost and no deformation of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

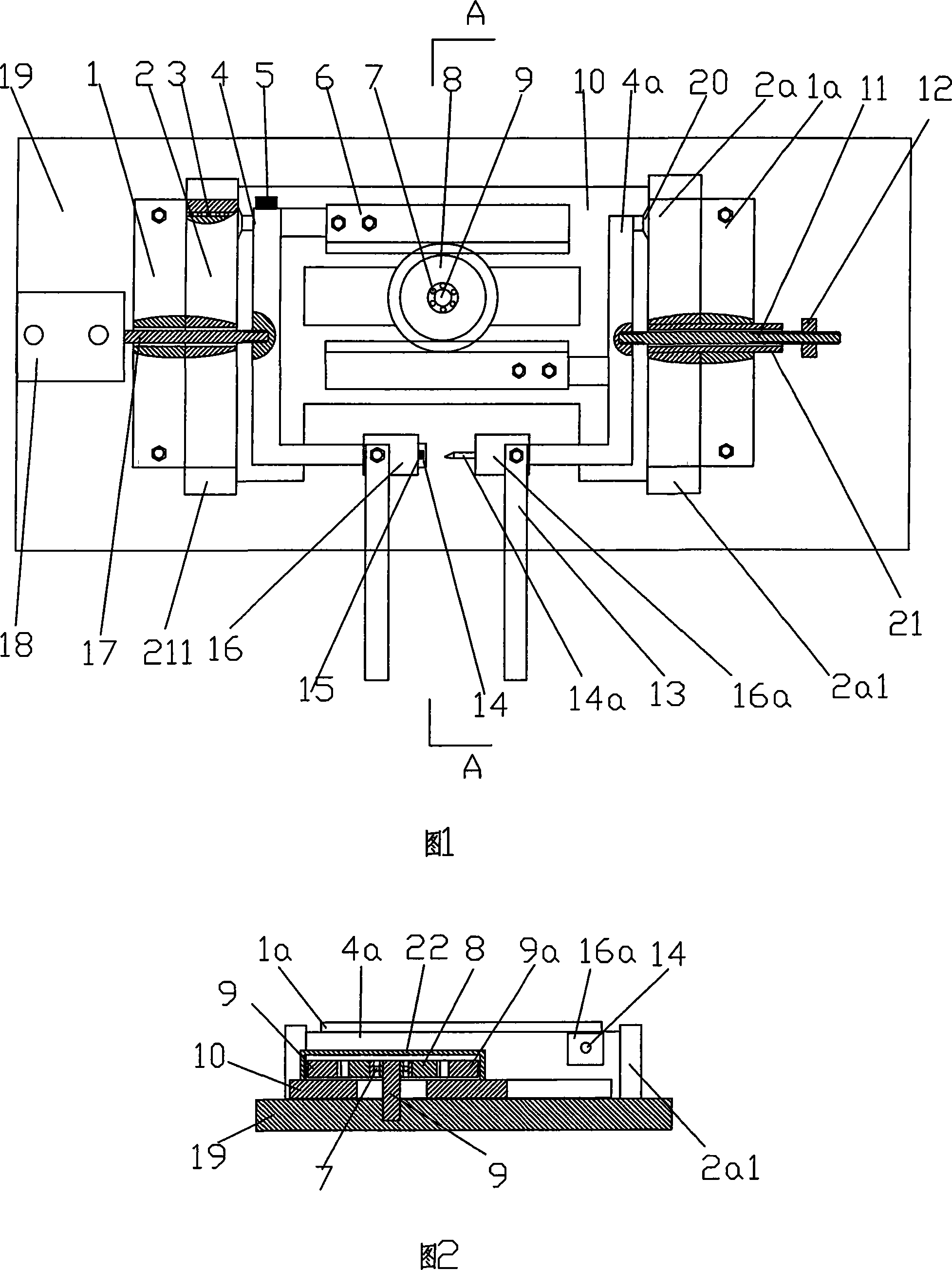

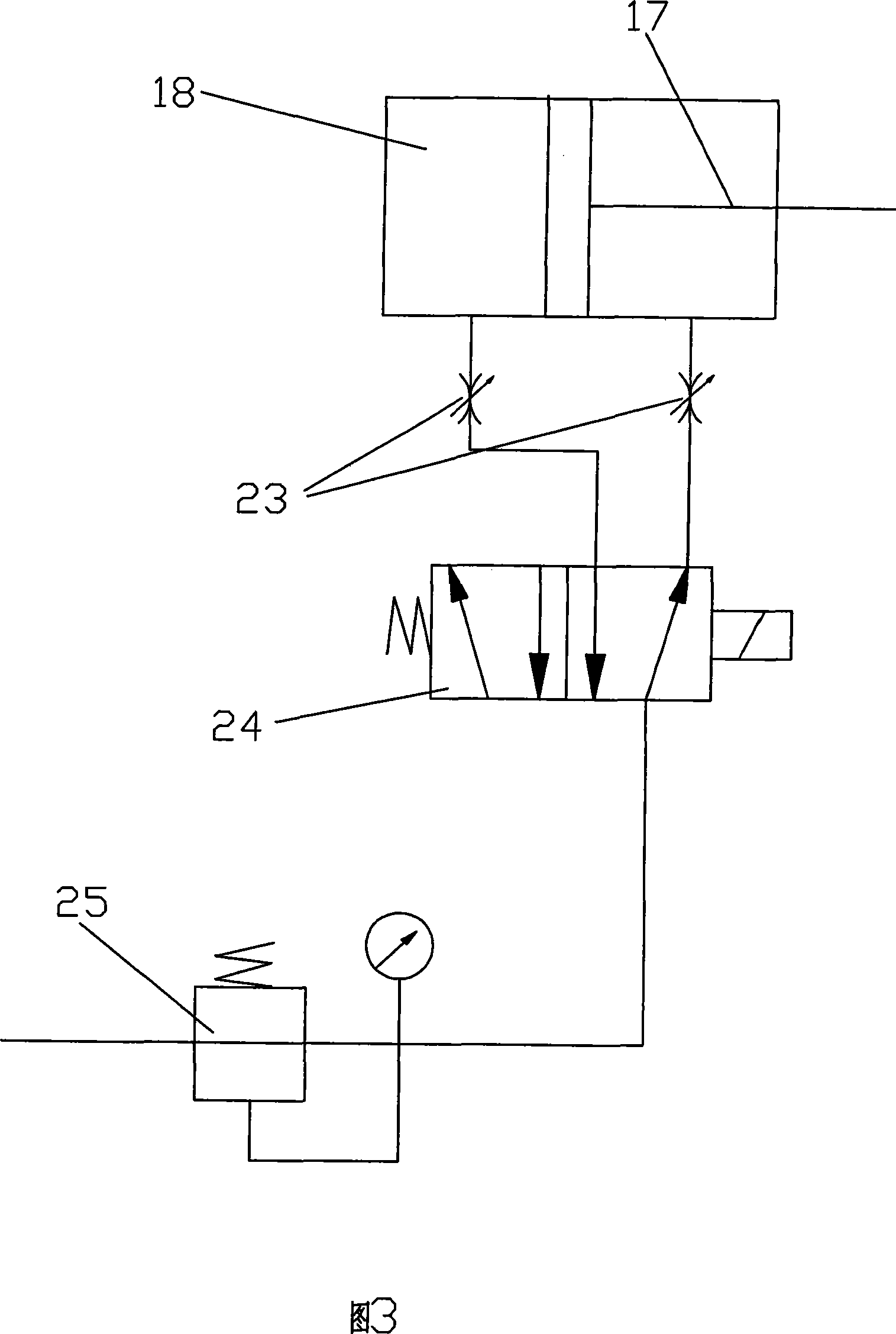

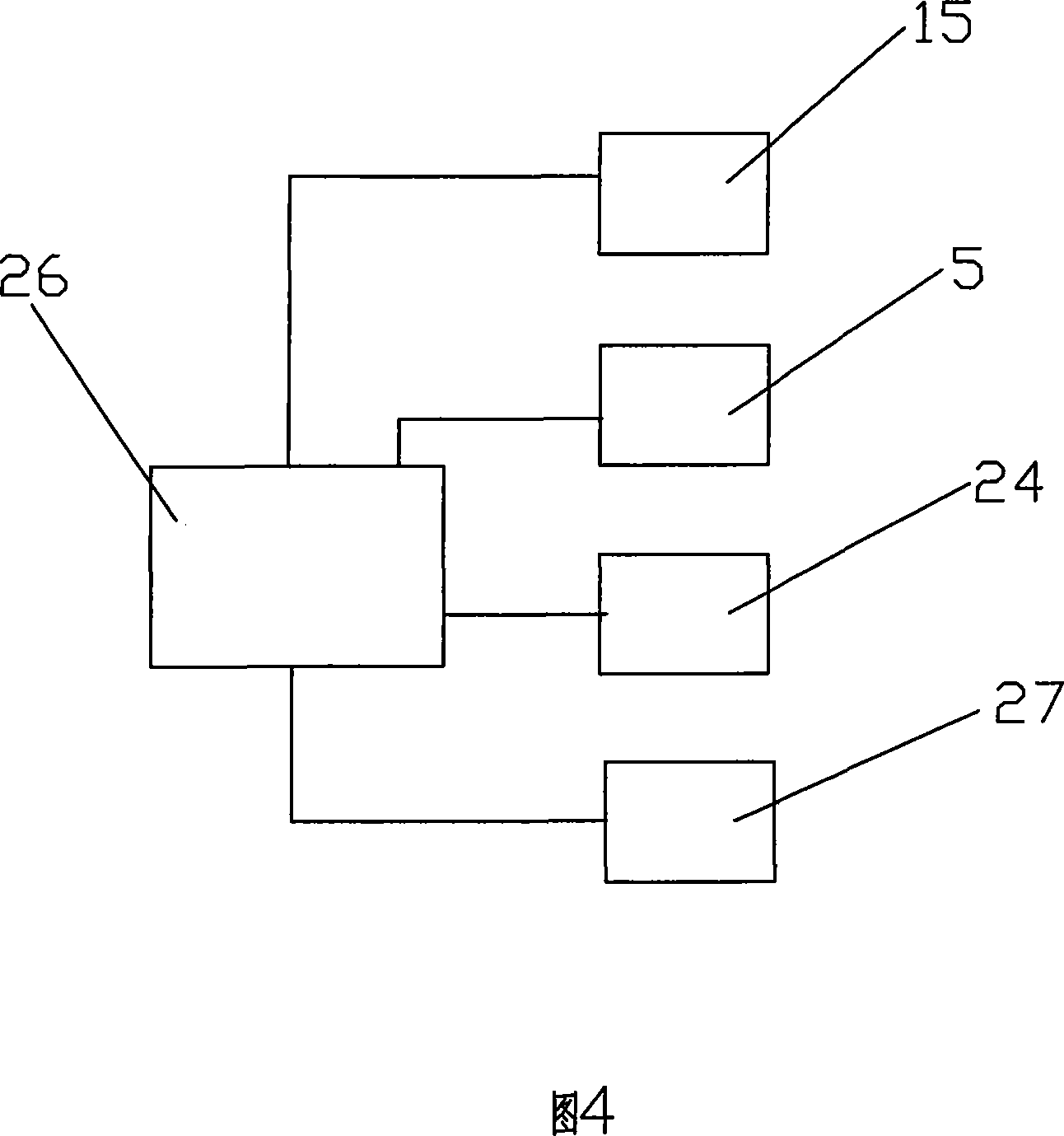

[0028] Fig. 1 is a schematic structural view of the present invention, and Fig. 2 is a sectional view along A-A of Fig. 1, as shown in the figure: the welding head of the single-cylinder double-action spot welding machine of the present embodiment comprises backing plate 19, is fixed on the backing plate The upper cylinder 18, the electrode holder 16, the electrode belt 13 connected with the electrode holder, the electrode 14 arranged on the electrode holder and the pressure displacement device, the pressure displacement device includes the left guide rod 2 fixed on the backing plate 19 by screws And right guide rod 2a, the left slide block 4 that is arranged between left guide rod 2 and the right guide rod 2a and the right slide block 4a, on backing plate 19, be provided with slide block seat 10 by screw fixing, left slide block 4 or right The slider 4 a is provided on the slider seat 10 .

[0029] The left guide rod 2 and the right guide rod 2a are provided with a slideway p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com