Method for producing casting fireproof material by negative pressure hollow type method

A technology of melting and casting refractory materials and negative pressure, applied in ceramic molding machines, manufacturing tools, etc., can solve problems such as increasing product production costs, wasting molding sand, and environmental pollution, and achieve the effects of cost reduction, product quality improvement, and environmental pollution elimination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

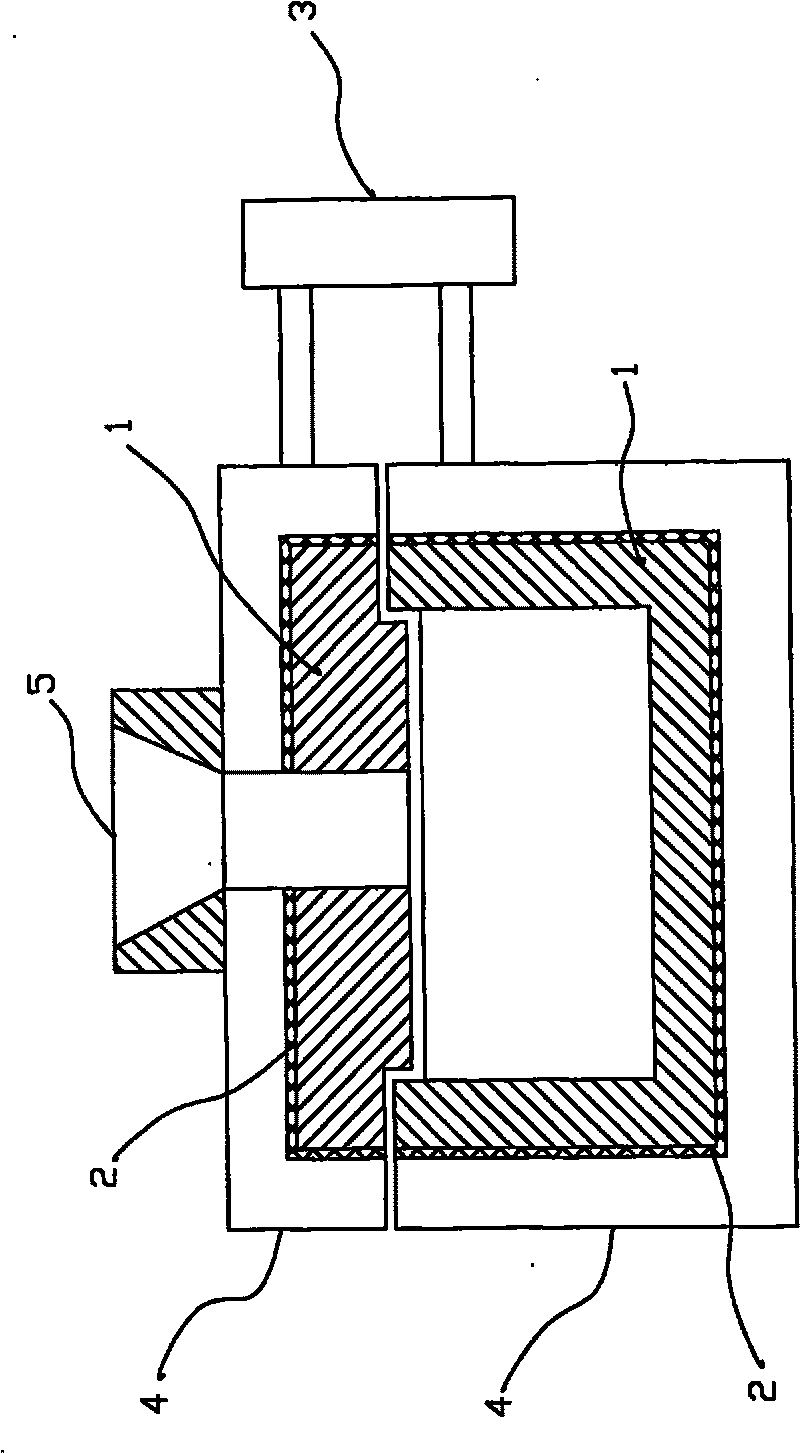

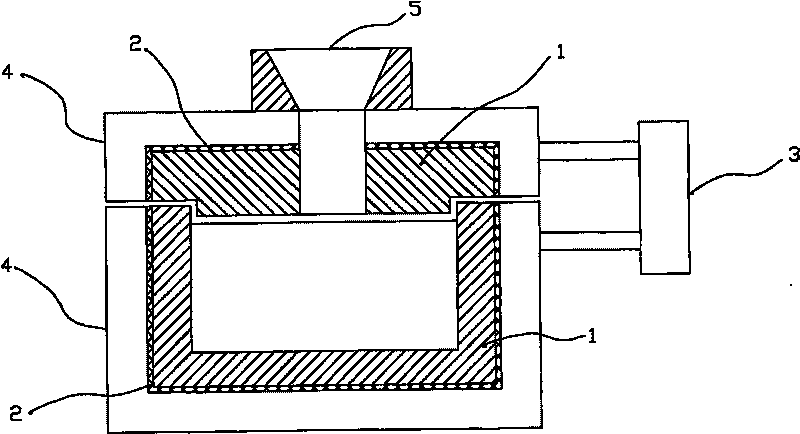

[0022] Such as figure 1 Shown, the negative pressure air type production method of casting refractory material of the present invention, it comprises following processing steps:

[0023] 1. According to the product size, the upper and lower split metal casting molds 1 of 300mm×400mm×600mm are made;

[0024] 2. Adsorb the polyethylene film 2 on the outer surface of the mold 1 by negative pressure;

[0025] 3. Put the mold 1 with the polyethylene film 2 obtained in the second step into the split sand box 4 with a negative pressure generating device 3 (vacuum pump can be used), bury the pure silica sand and shake it with a vibrator After the vacuum pump 3 stops working, after the mold 1 is taken out from the sand box 4, an empty cavity surrounded by polyethylene film 2 is obtained in the sand box 4;

[0026] 4. Cast the molten AZS refractory solution melted in the electric furnace in a traditional way through the exhaust spout 5 on the upper top mold 1 into the empty cavity mad...

Embodiment 2

[0029] Such as figure 1 Shown, the negative pressure air type production method of casting refractory material of the present invention, it comprises following processing steps:

[0030] 1. According to the product size, make an upper and lower split hollow wooden mold 1 of 300mm×400mm×600mm;

[0031] 2. Adsorb the polyvinyl chloride film 2 on the outer surface of the mold 1 by using negative pressure;

[0032] Three, put the mold 1 with the polyvinyl chloride film 2 obtained in the second step into the sand box 4 with the negative pressure generating device 3 (can use a vacuum pump), and bury the aluminum oxide hollow balls (keep the hollow balls in the hollow balls) The particle size is less than 50 microns (no more than 10% of the total weight), shake with a vibrator to make it evenly filled, and then use the vacuum pump 3 to extract the internal air; Promptly obtain the empty cavity surrounded by polyvinyl chloride film 2 in case 4;

[0033] 4. Cast the fused alumina re...

Embodiment 3

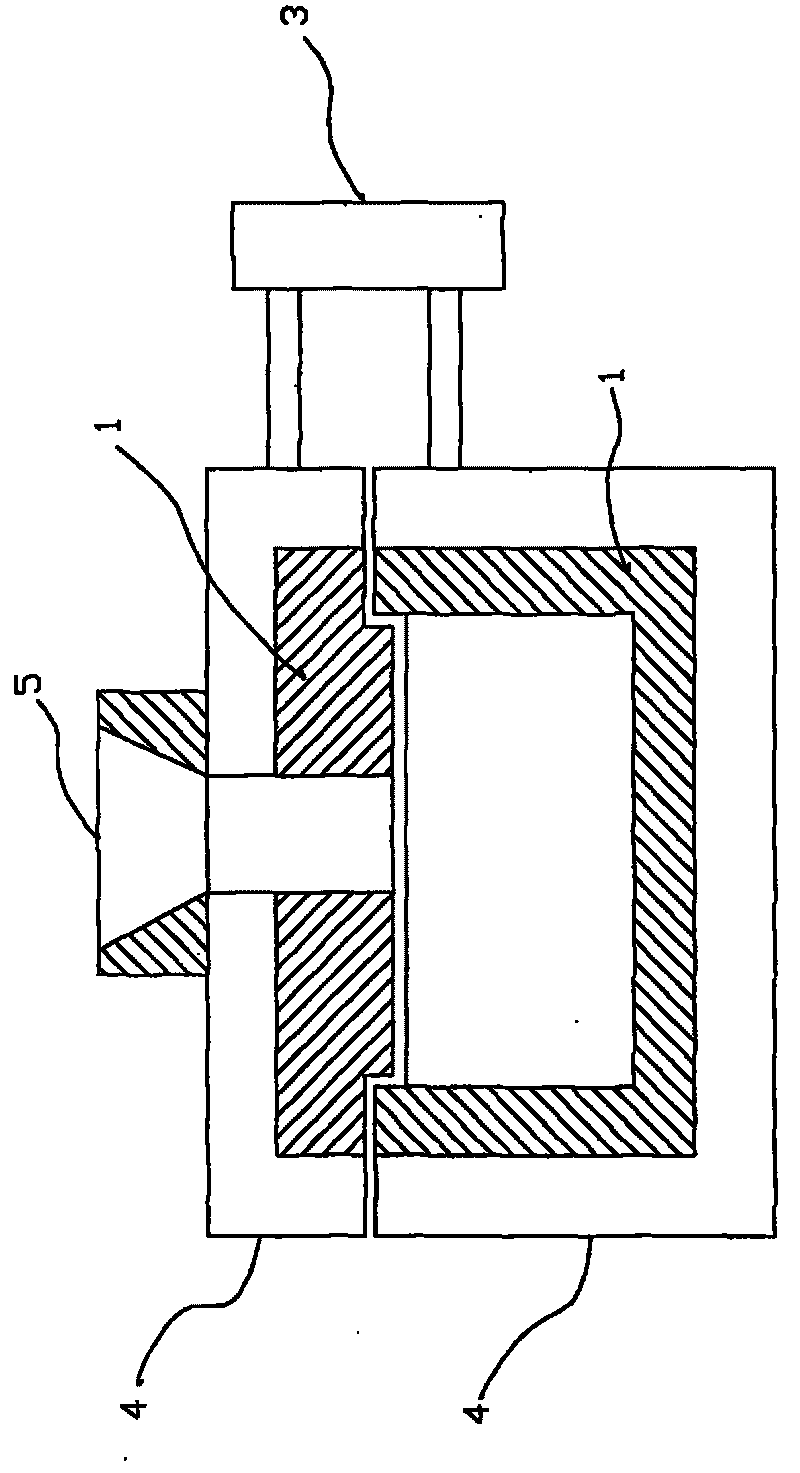

[0036] Such as figure 2 Shown, the negative pressure air type production method of casting refractory material of the present invention, it comprises following processing steps:

[0037] The first step is to make upper and lower split hollow molds 1 with foam according to the shape of the product;

[0038] The second step is to put the hollow mold 1 into the sand box 4 with the negative pressure generating device 3 (vacuum pump), bury the casting sand, vibrate it with a vibrator to make it evenly filled, and then use the vacuum pump 3 to extract the internal air;

[0039] The third step is to directly cast the melted refractory material solution into the foam hollow mold 1 through the exhaust spout 5 on the top mold by traditional technology, start the vacuum pump 3, keep the negative pressure state, and release the negative pressure after the melt is solidified. Press, and get the finished product after cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com