Multi-micropore polyester fiber and preparation method thereof

A polyester fiber, microporous technology, applied in the field of textile fiber and manufacturing, can solve the problems of poor durability, moisture absorption, poor air permeability, limited hydrophilic properties of fibers, etc., and achieve excellent moisture absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

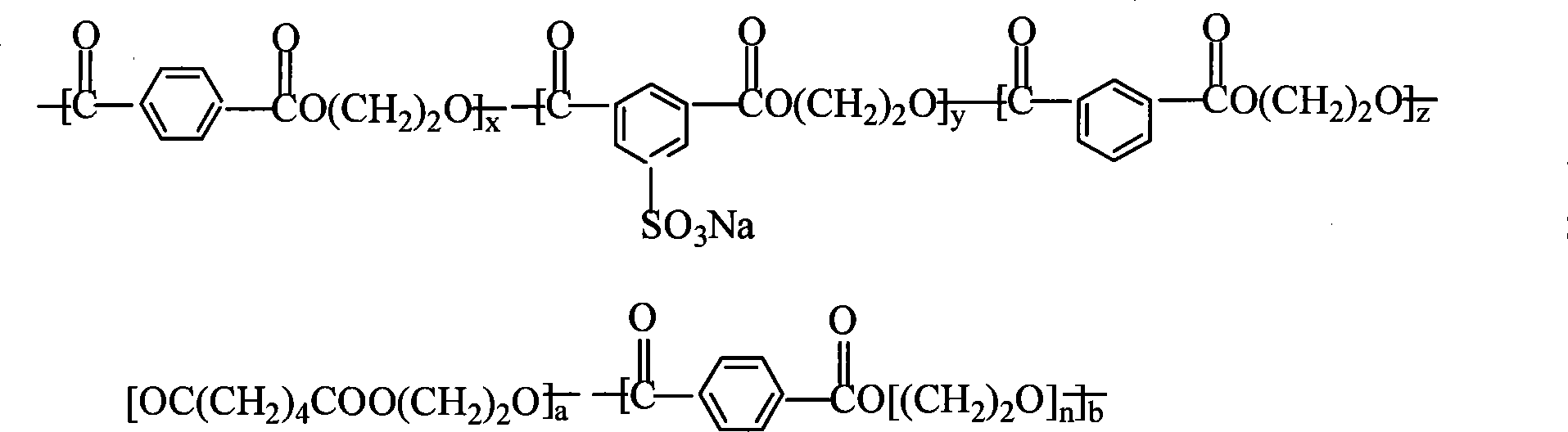

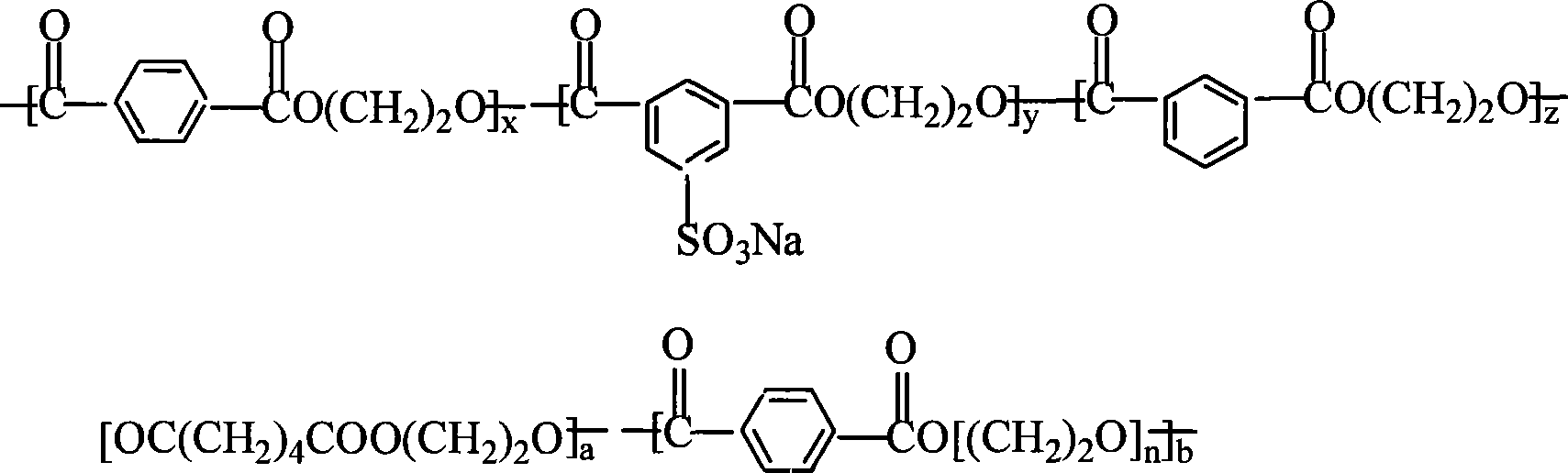

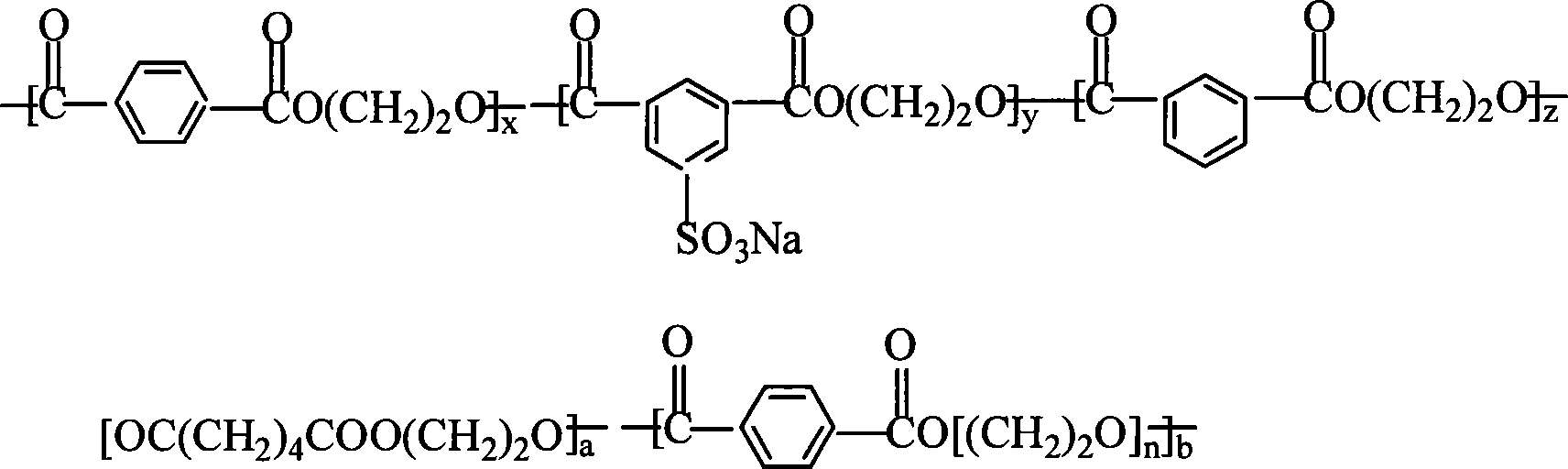

[0020] A preparation method of the above-mentioned microporous polyester fiber, which adopts a water-soluble, water-soluble polymer with excellent hygroscopicity and ionic conductivity as a dissolving component, which is dried and pulverized The 75-85 mesh fine particles are uniformly blended with conventional polyester particles of the same size in a ratio of 30-50%: 70-50%, and extruded and granulated on a twin-screw extruder; the masterbatch has been dried. After melt spinning, stretching, and dissolving the filament in hot water for 55-65 minutes, the dissolution weight loss rate reaches 8-12%, and then it is taken out and dried, so that 20-40% of the water-solubility remains in the fiber. The polymer component has a large number of micropores with a diameter of about 0.5-2um, which are uniformly distributed on the surface and inside, and have excellent moisture absorption and air permeability.

[0021] The present invention adopts a water-soluble polymer that is soluble i...

Embodiment 1

[0029] Example 1: The present invention adopts the dissolution method to prepare the microporous polyester fiber, and the polymer added with the water-soluble modifier is dried and pulverized into 80 mesh fine particles, which are 30%: 70% with the conventional polyester particles of the same size. The proportion is uniformly blended, extruded and granulated on a twin-screw extruder, and the masterbatch containing water-soluble components that has been made is melt-spun and stretched after drying, and the filament is dissolved in hot water at 100 ° C. After 60 minutes, the dissolution weight loss rate reached 10%. It was taken out and dried. The electron microscope test showed that a large number of micropores with a diameter of about 0.5-2um in diameter were generated on the surface and inside of the fiber. Since the fiber still retains 20% hydrophilic It is a water-soluble polymer component with good properties, with a large number of micropores with a diameter of 0.5-2um on ...

Embodiment 2

[0030] Example 2: The invention adopts the dissolution method to prepare the microporous polyester fiber, and the polymer added with the water-soluble modifier is dried and pulverized into fine particles of 85 meshes, which are 50%:50% with the conventional polyester particles of the same size. The proportion is uniformly blended, extruded and granulated on a twin-screw extruder, and the masterbatch containing water-soluble components that has been made is melt-spun and stretched after drying, and the filament is dissolved in hot water at 100 ° C. After 55 minutes, the dissolution weight loss rate reached 8%. It was taken out and dried. The electron microscope test showed that a large number of micropores with a diameter of about 0.5-2um were generated on the surface and inside of the fiber. Since the fiber still retains 40% hydrophilic It is a water-soluble polymer component with good properties, with a large number of micropores with a diameter of 0.5-2um on the surface and i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com