Multi-pipe impulse detonating combustion camber and detonation method thereof

A technology of pulse detonation and detonation method, which is applied in the power field and can solve the problems of reduced mixture sensitivity, complicated pulse detonation engine, and increased ignition delay time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

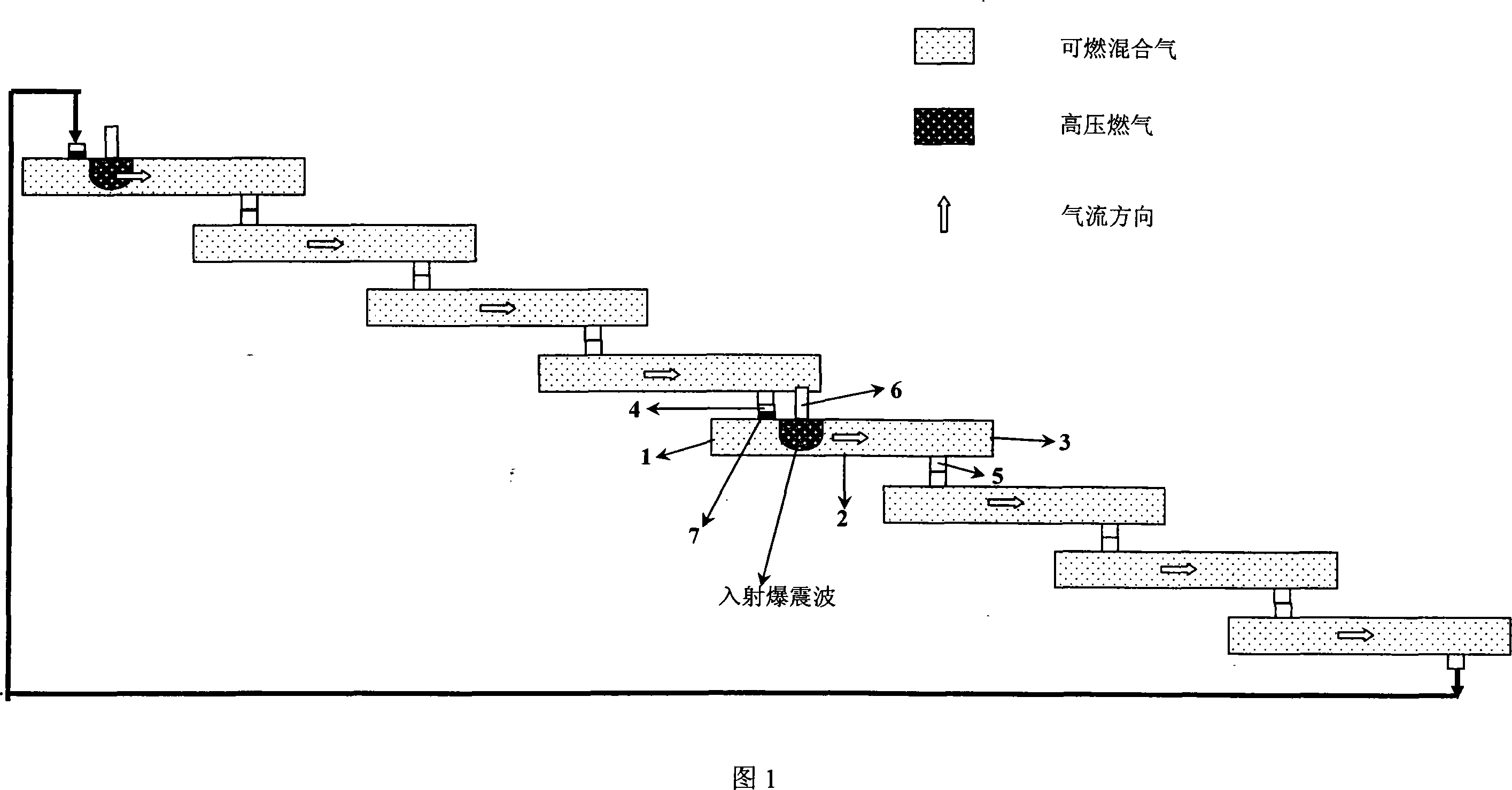

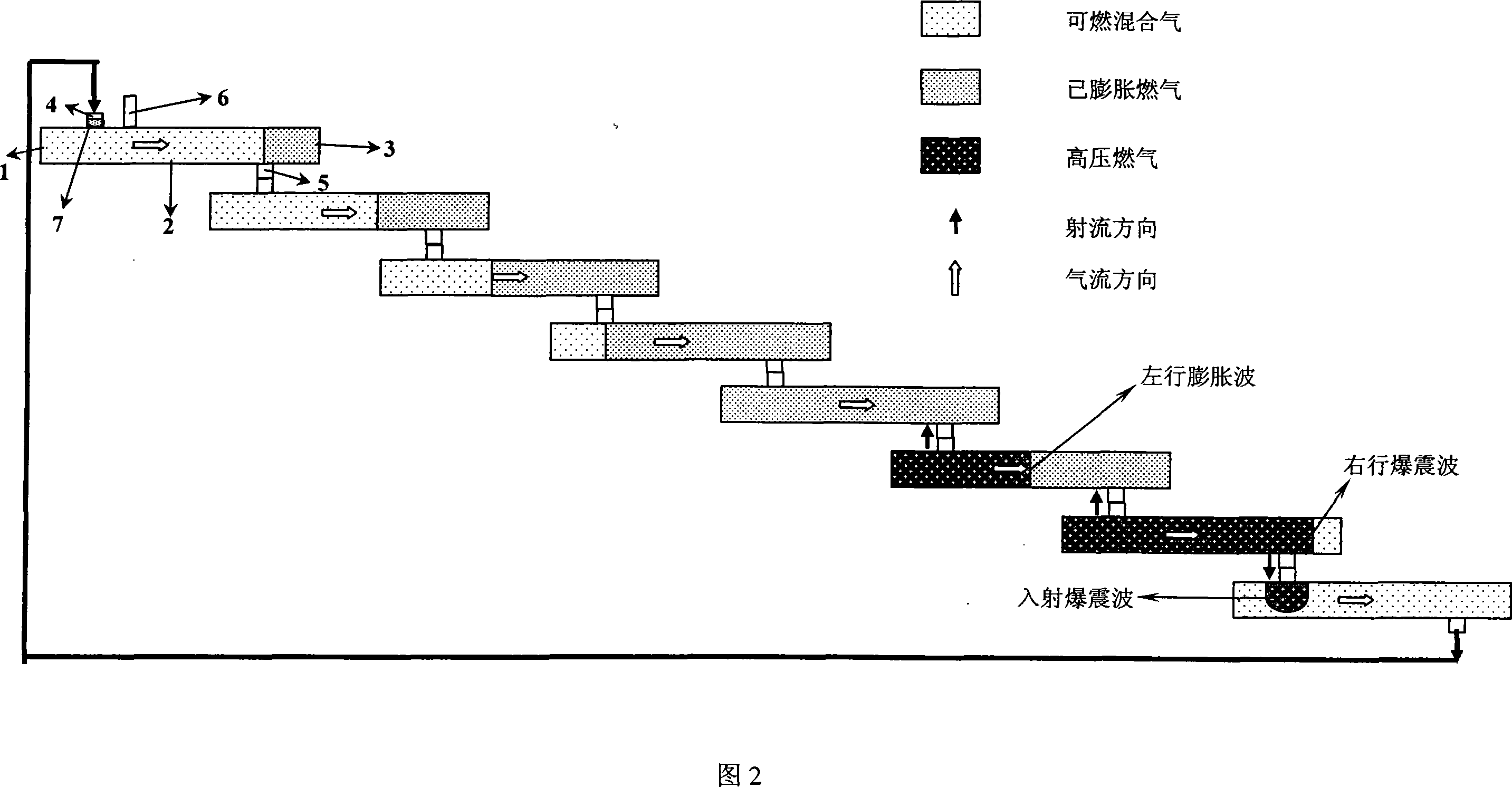

Method used

Image

Examples

Embodiment 2

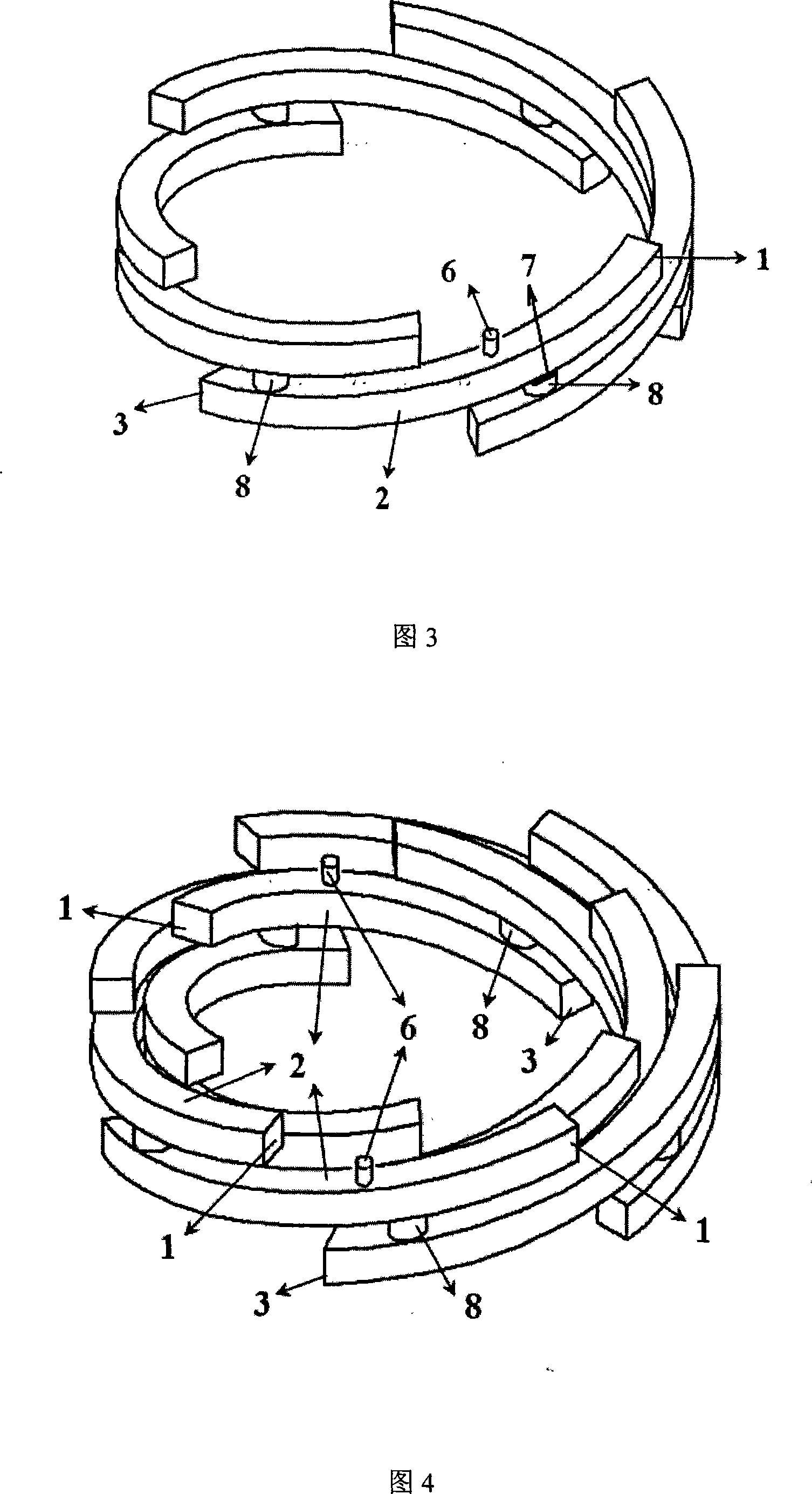

[0023] Device embodiment 2: referring to Fig. 4, it includes two ring-shaped multi-tube pulse detonation combustion chambers, and each ring of multi-tube pulse detonation combustion chambers is respectively connected together by 6 detonation units through the jet propagation pipe 8, Each detonation unit includes a detonation chamber inlet 1, a detonation chamber 2, a detonation chamber outlet 3 and a jet propagation pipe 8, and the jet propagation pipe 8 includes the detonation jet outlet 5 and the lower detonation jet outlet of the upper detonation unit connected together. The detonation jet inlet 4 of the primary detonation unit, the detonation chamber inlet 1 and the detonation chamber outlet 3 are located at both ends of the detonation chamber 2, the detonation chamber inlet 1 is at the most upstream, and the detonation jet inlet 4 is close to and located at the detonation chamber entrance Downstream of 1, the detonation jet outlet 5 is close to and located upstream of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com