Composite reinforced pnenolic aldehyde foam insulating board and its preparation method

A technology of phenolic foam and thermal insulation board, which is applied in thermal insulation, pipeline protection, mechanical equipment, etc. It can solve the problems of insufficient board strength, easy pulverization, and low bonding strength between the board and the surface layer, so as to improve the physical strength and adhesion. The effect of improving the connection performance and expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

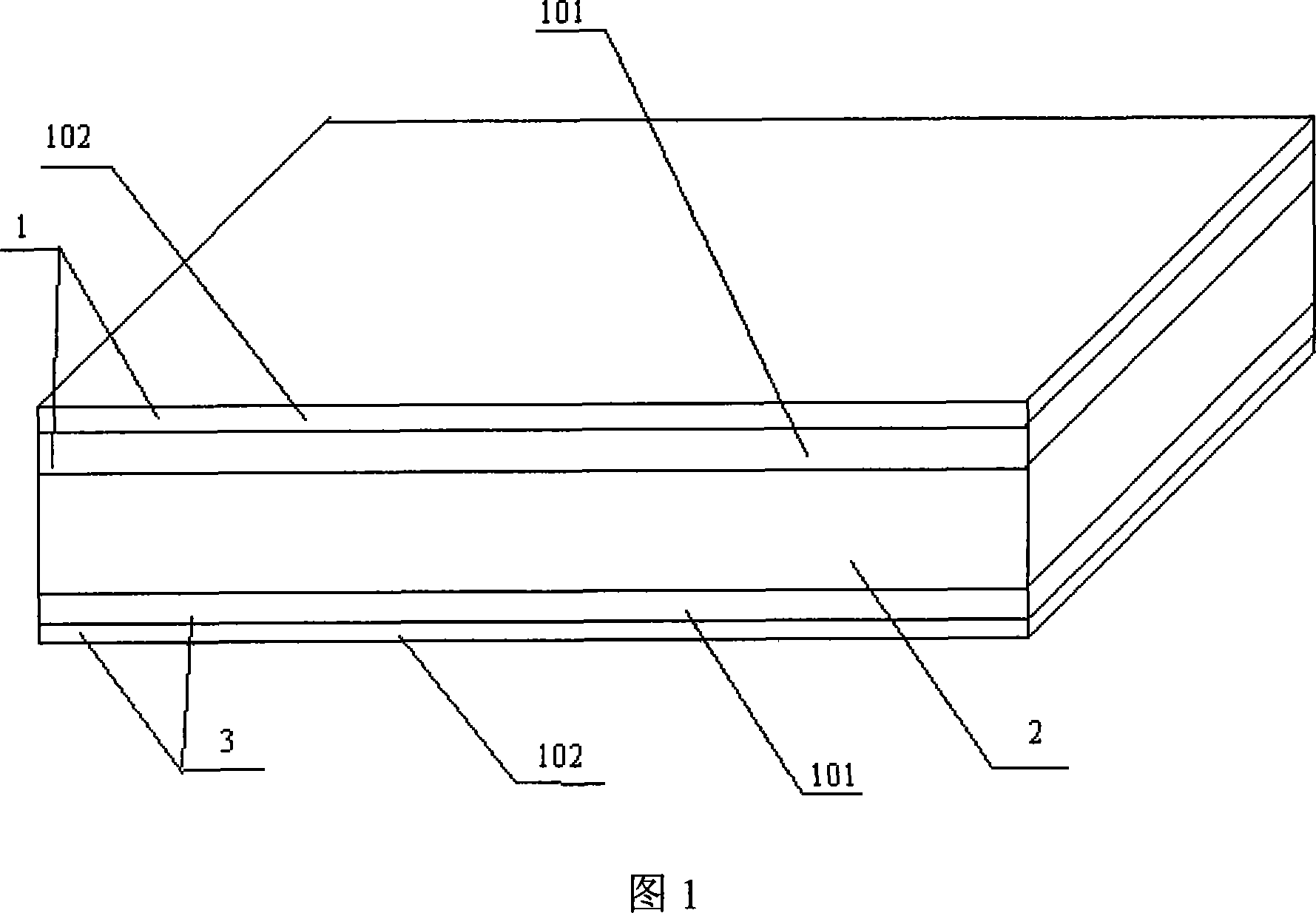

[0037] The continuous foam molding process is adopted to prepare composite reinforced phenolic foam insulation boards with a thickness of 20mm. The surface layer material is glass fiber veneer felt, model EMS-50-1250, the performance is tested, and the performance is listed in Table 2. It can be seen that, compared with Comparative Example 1, the compression and bending properties of the plate are greatly improved.

Embodiment 4

[0039] On the basis of the composite reinforced phenolic foam insulation board prepared in Example 3, another layer material, 0.07mm embossed aluminum foil, was compounded, and neoprene was used as the composite adhesive to obtain a new type of composite reinforced phenolic foam insulation board. Test performance, the performance is listed in Table 2. It can be seen that compared with Comparative Example 2, the compression and bending properties of the plate and the adhesive force of the aluminum foil are greatly improved.

Embodiment 5

[0041] On the basis of the composite reinforced phenolic foam insulation board prepared in Example 3, another layer material, 0.03mm embossed aluminum foil, was compounded, and neoprene was used as the composite adhesive to obtain a new type of composite reinforced phenolic foam insulation board. Test performance, the performance is listed in Table 2. It can be seen that compared with Comparative Example 2, the compression and bending properties of the plate and the adhesive force of the aluminum foil are greatly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com