High voltage tolerance element and producing method thereof

A technology of voltage components and manufacturing methods, applied in the field of electrostatic discharge protection circuits, can solve problems such as failure, damage, and poor coverage of ESD protection circuits, and achieve the effect of reducing leakage current and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

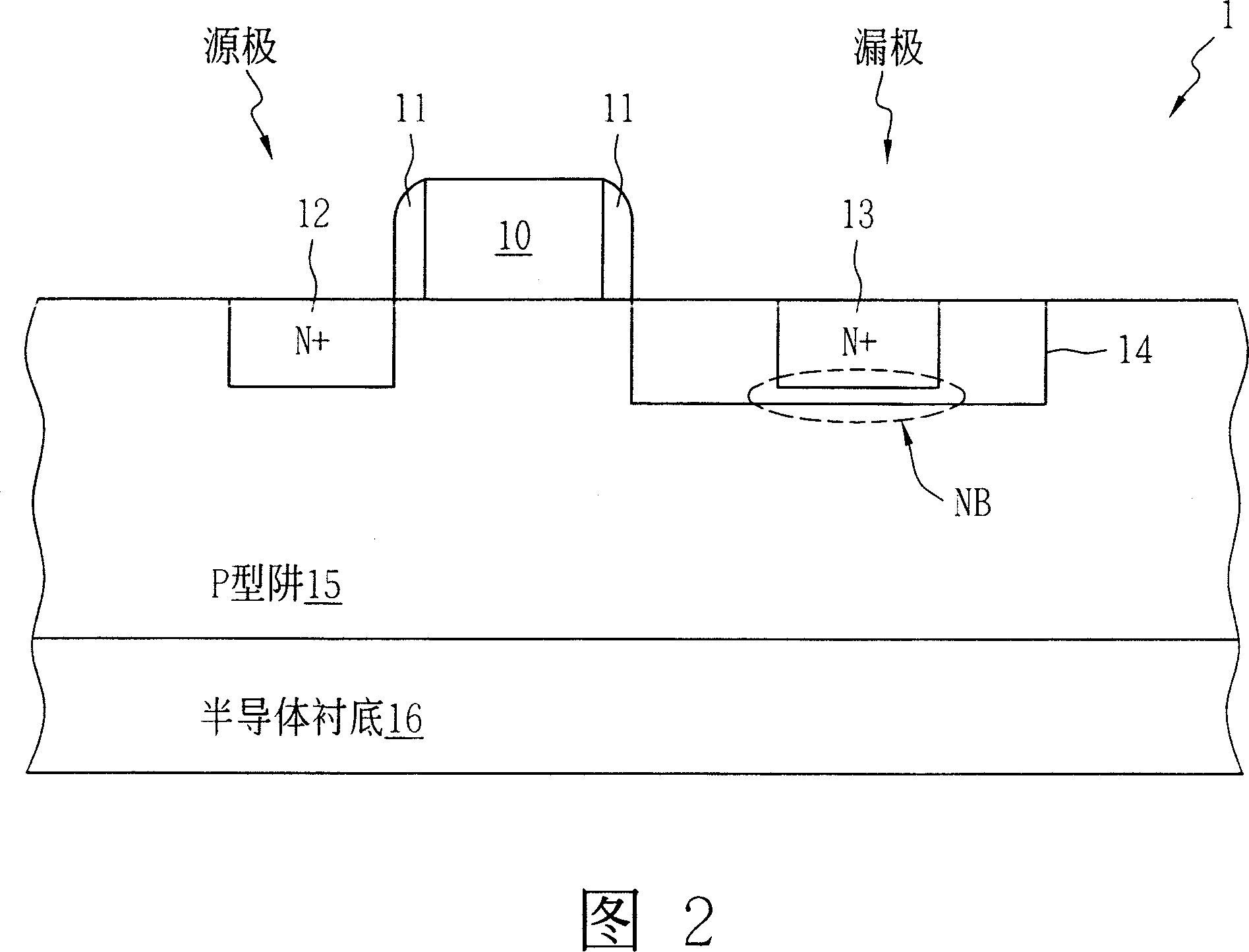

[0019]FIG. 4 is a schematic cross-sectional view of the structure of the high voltage resistant element 2 of the present invention. The high voltage device 2 includes a semiconductor substrate 27 and a gate 20 disposed between two spacers 21 . The semiconductor substrate 27 includes a P-type well region 26, an N-type second doped region 22, an N-type third doped region 23, and an N-type third doped region surrounding the N-type third doped region 23. Four doped regions 24 and an N-type fifth doped region 25 surrounding the N-type third doped region 23 . The gate 20 is used to control the conduction between the N-type second doped region 22 and the N-type third doped region 23 . The length L2 of the N-type fourth doped region 24 is greater than the length L1 of the N-type fifth doped region 25, and the depth D1 of the N-type fifth doped region 25 is greater than the N-type fourth doped region 25. The depth D2 of the impurity region 24. Therefore, the N-type fifth doped regio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com