Vertically and horizontally walking small tiller

A micro-cultivator, walking deceleration technology, applied in the direction of land preparation machinery, guiding agricultural machinery, agricultural machinery chassis, etc., can solve the problems that modern agriculture cannot be advanced, fixed support points are not easy to place, and are not firm, and achieve improvement. Vegetable planting environment, improvement of vegetable planting environment, and guaranteed flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

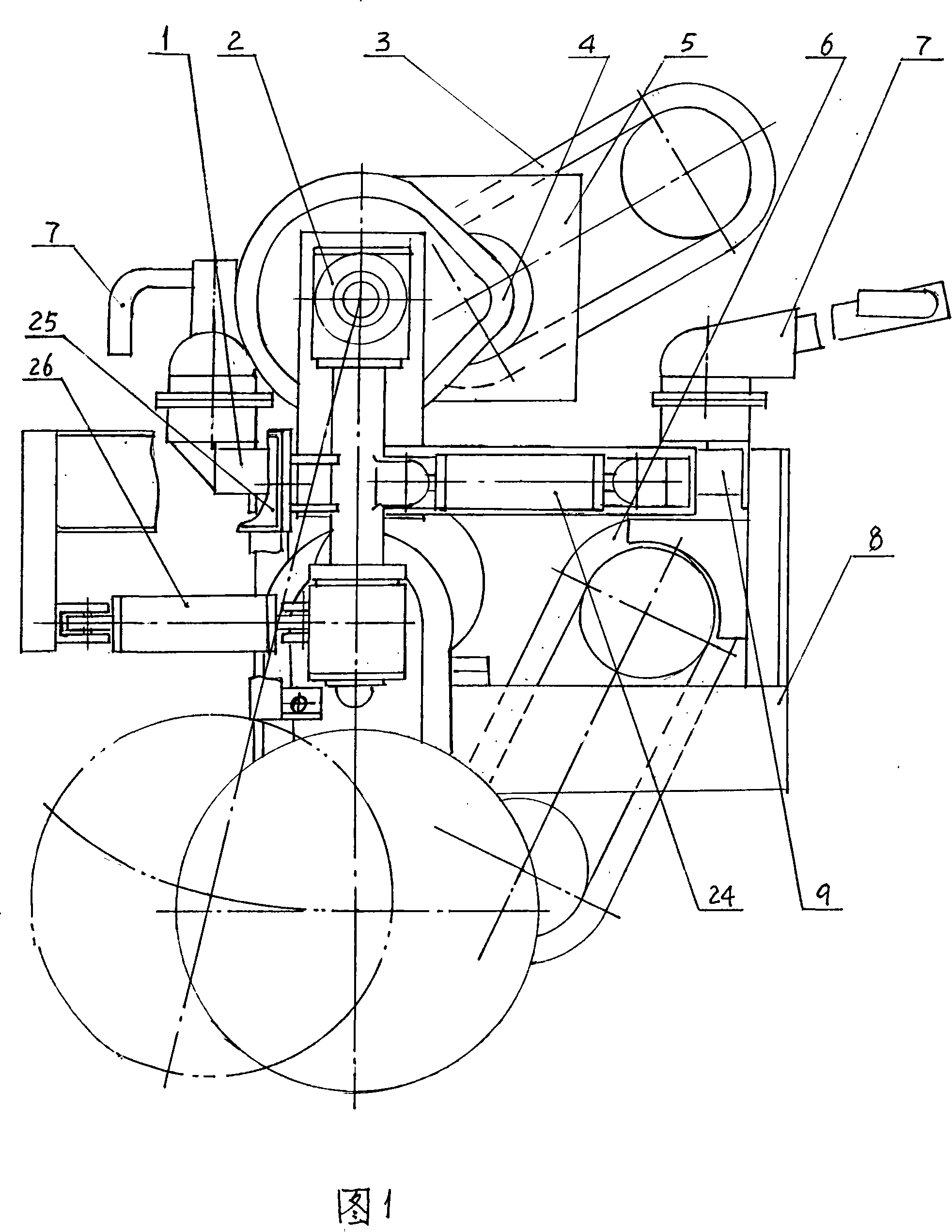

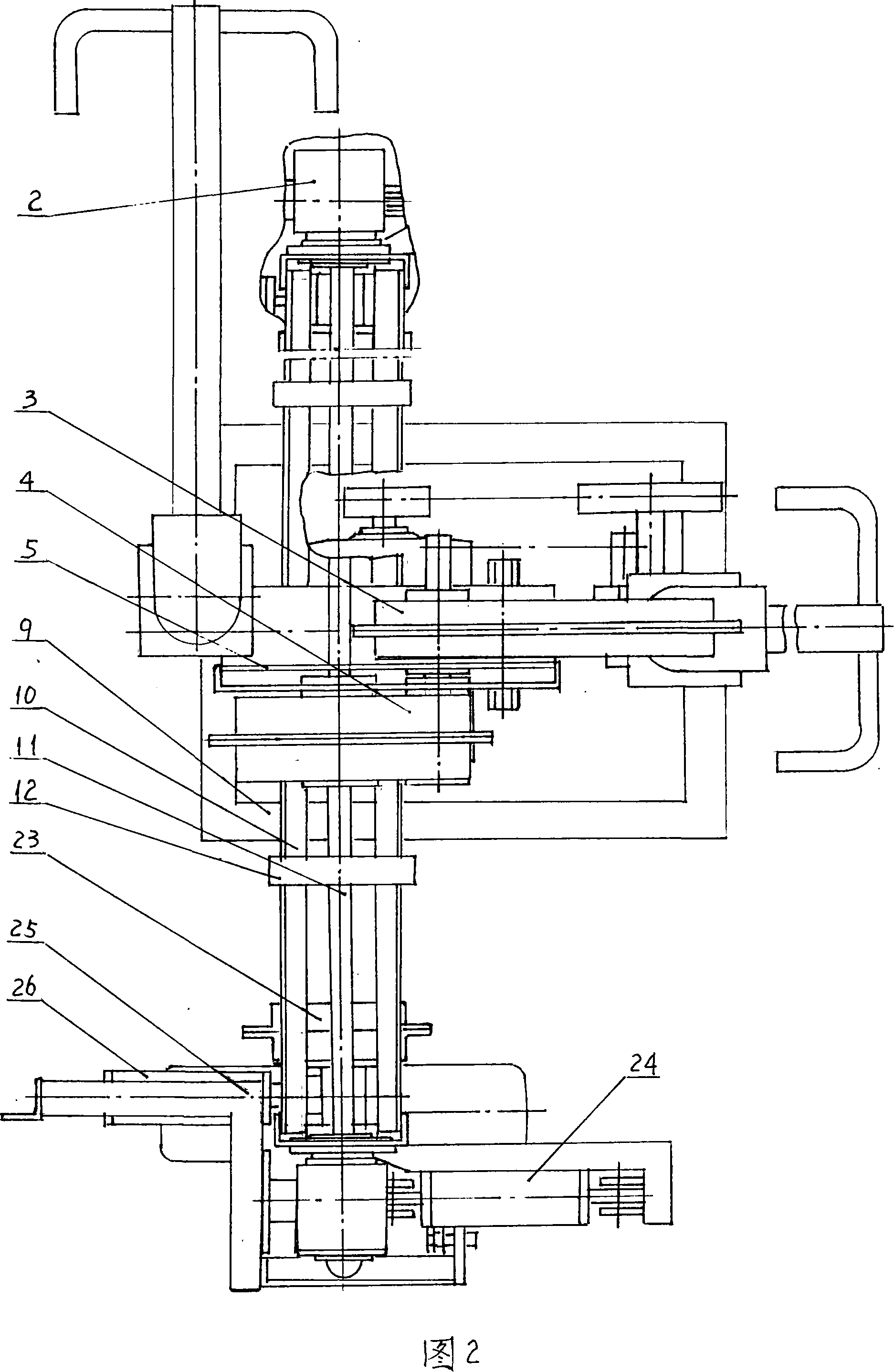

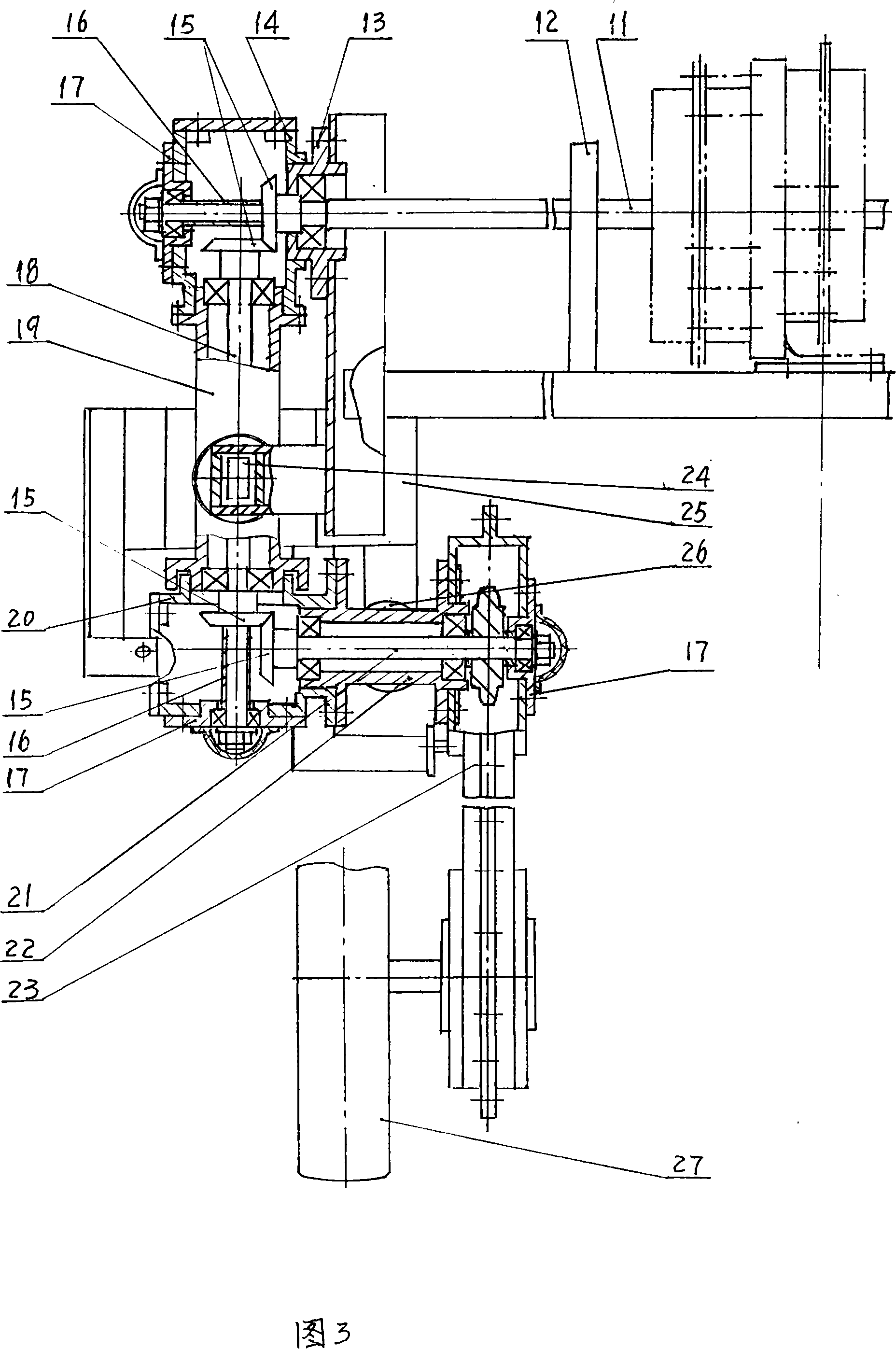

[0026] As shown in Figure 1, after the drive axle (2), the main transmission tongs (3), the travel reducer (4) and the seat frame (5) are connected and fastened, their positions must first meet the requirements of the final drive shaft of the main gearbox (3) The center distance of the two sprockets between the extension shaft end and the input shaft of the coulter transmission box (6) is required, and the four are moved back and forth on the longitudinal top beam (9) to reach the center distance requirements of the two sprockets and tightened, the main transmission The center distance between the pulley of the box (3) and the power pulley is adjusted, and the power machine moves forward and backward to meet the belt tension requirements, thus ensuring the external transmission quality; the longitudinal bottom beam (8) and the longitudinal top beam (1) The setting of 9) can provide diversified connection positions for different types of power machines; the drive axle (2) is fasten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com