Cabin circumstance control system used for passenger plane

A control system and cockpit technology, applied in the field of refrigeration ventilation control system and cockpit environment dehumidification, can solve the problems of poor ventilation gas quality, high noise, high energy consumption, etc., and achieve the effect of reducing heat exchange load, reducing noise, and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

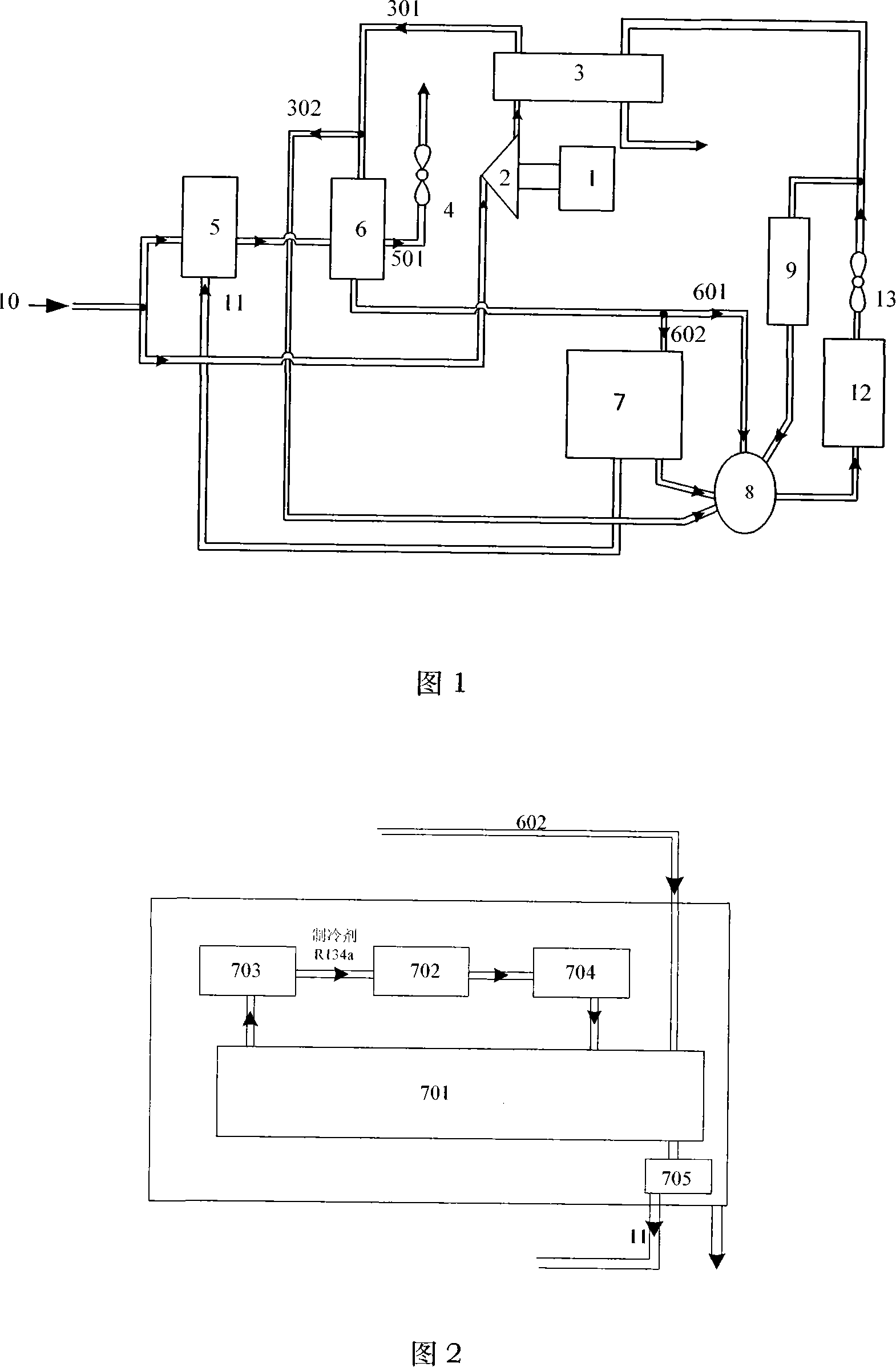

[0020] The cockpit environment control system of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] As shown in Figure 1, the components that the environmental control system of the present invention comprises include: frequency conversion motor 1, supercharger 2, frequency conversion motor 1 is used to drive supercharger 2 to work; The supercharger 2 exhausts the air for the first step of cooling; the air-inducing device A4 extracts the gas E501 in the secondary heat exchanger 6 and discharges it into the atmosphere; the water spray precooler 5 cools the ram air 10 The secondary heat exchanger 6 performs the second step of cooling the gas A301 discharged from the recovery heat exchanger 3; the evaporative cycle refrigeration device 7 performs the third step of cooling and dehumidification treatment on the gas D602 discharged from the secondary heat exchanger 6; The air-conditioning air mixing chamber 8 is used to mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com