A method for preparing stephanoporate starch bark beetle attractant slow release ball granule preparion

A technology of porous starch and slow-release preparations, which is applied in the fields of attractants, botanical equipment and methods, chemicals for biological control, etc. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

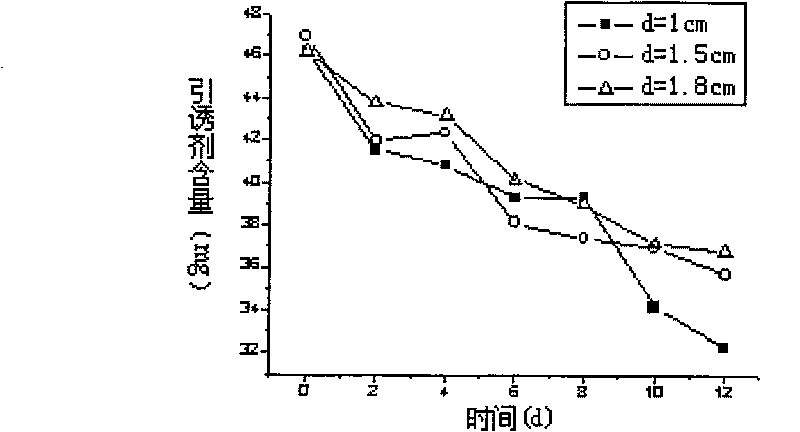

[0019] The 150-mesh porous starch was uniformly mixed with a sufficient amount of bark beetle attractant to make pellets with diameters of 1.0 cm, 1.5 cm, and 1.8 cm, respectively, to obtain a single-layer sustained-release preparation of bark beetle attractant pellets.

Embodiment 2

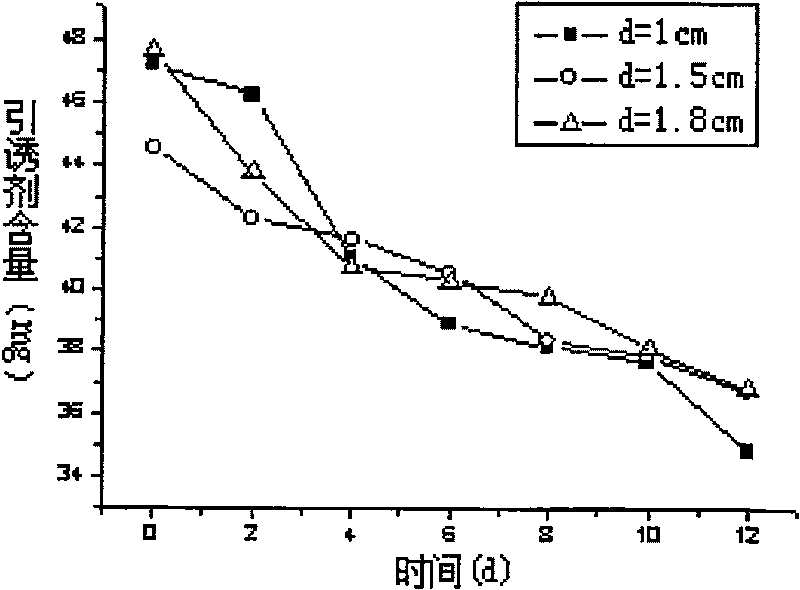

[0021] Mix 150-mesh porous starch with sufficient bark beetle attractant evenly to make pellets with diameters of 1.0cm, 1.5cm, and 1.8cm, and put the prepared pellets into a mass percent concentration of 5% to form high The polymer compound (such as: polyvinyl alcohol) solution of the molecular film, and then soaked in a cross-linking agent (such as: boric acid) saturated solution for 10 minutes to fully cure the polymer film, take it out, and dry it naturally to make a bark beetle attractant Pellet double sustained release formulation.

Embodiment 3

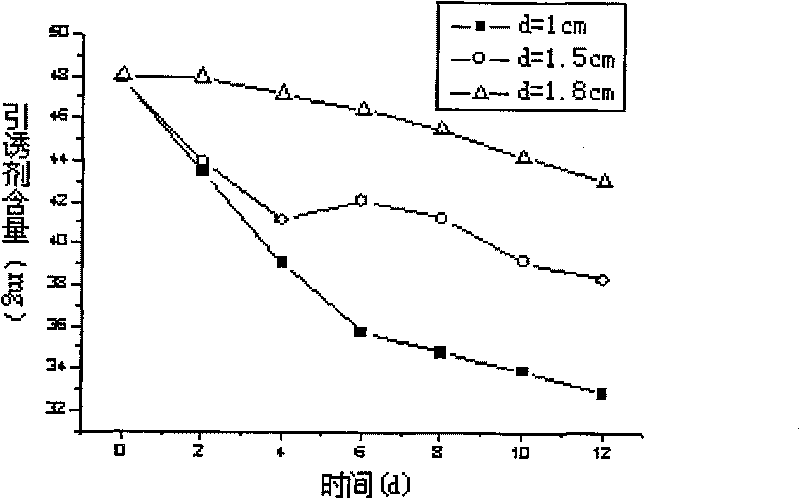

[0023] Mix 150-mesh porous starch with sufficient bark beetle attractant evenly to make pellets with diameters of 1.0cm, 1.5cm, and 1.8cm, and put the prepared pellets into a mass percent concentration of 10% to form high The polymer compound (such as: polyvinyl alcohol) solution of the molecular film, and then soaked in a cross-linking agent (such as: boric acid) saturated solution for 10 minutes to fully cure the polymer film, take it out, and dry it naturally to make a bark beetle attractant Pellet double sustained release formulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com