Inflatable skeleton structure blade

An inflatable skeleton and blade technology, applied in the direction of climate sustainability, reduction of greenhouse gases, engines, etc., can solve the problems of high manufacturing cost, difficult manufacturing technology, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

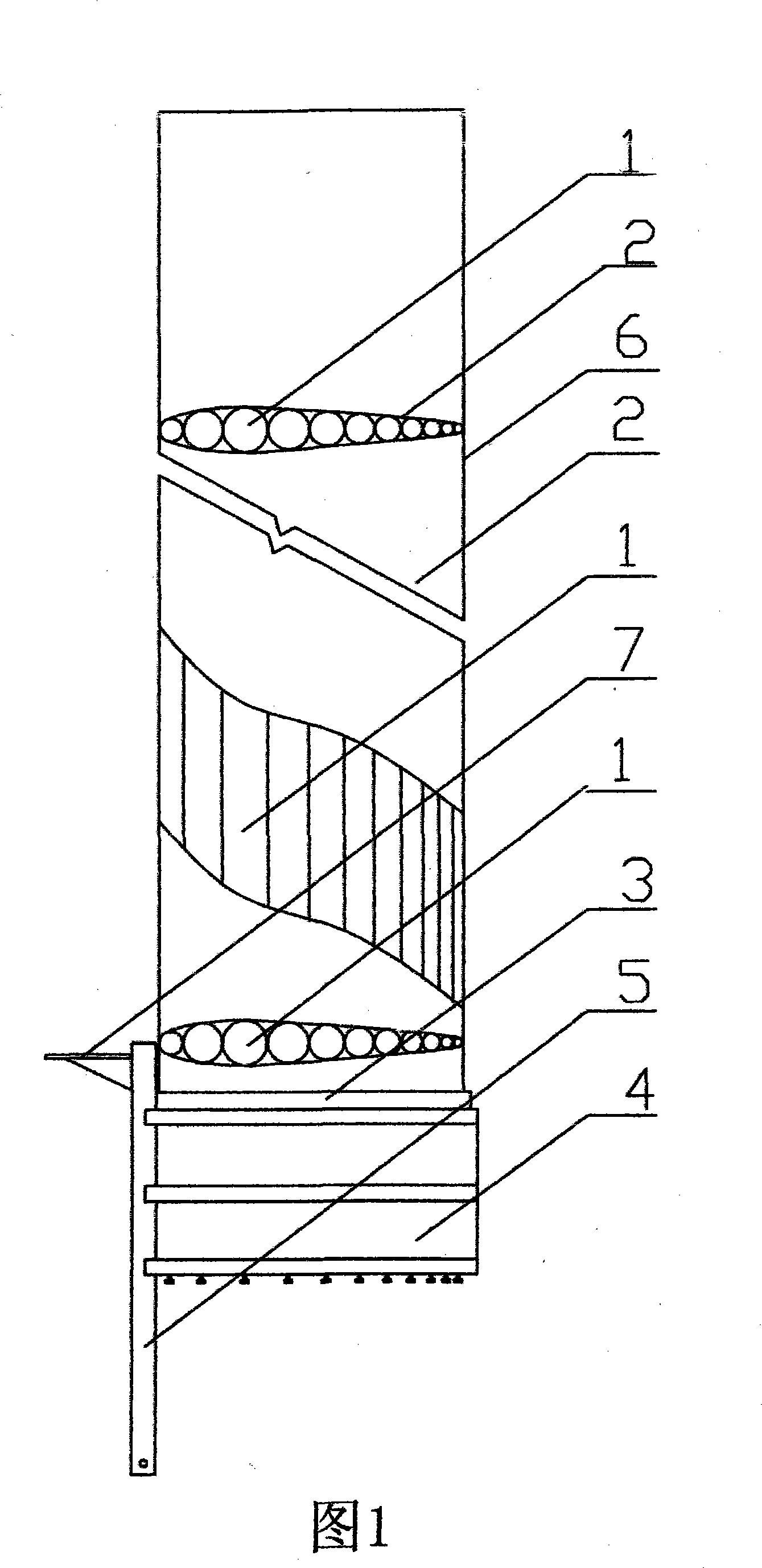

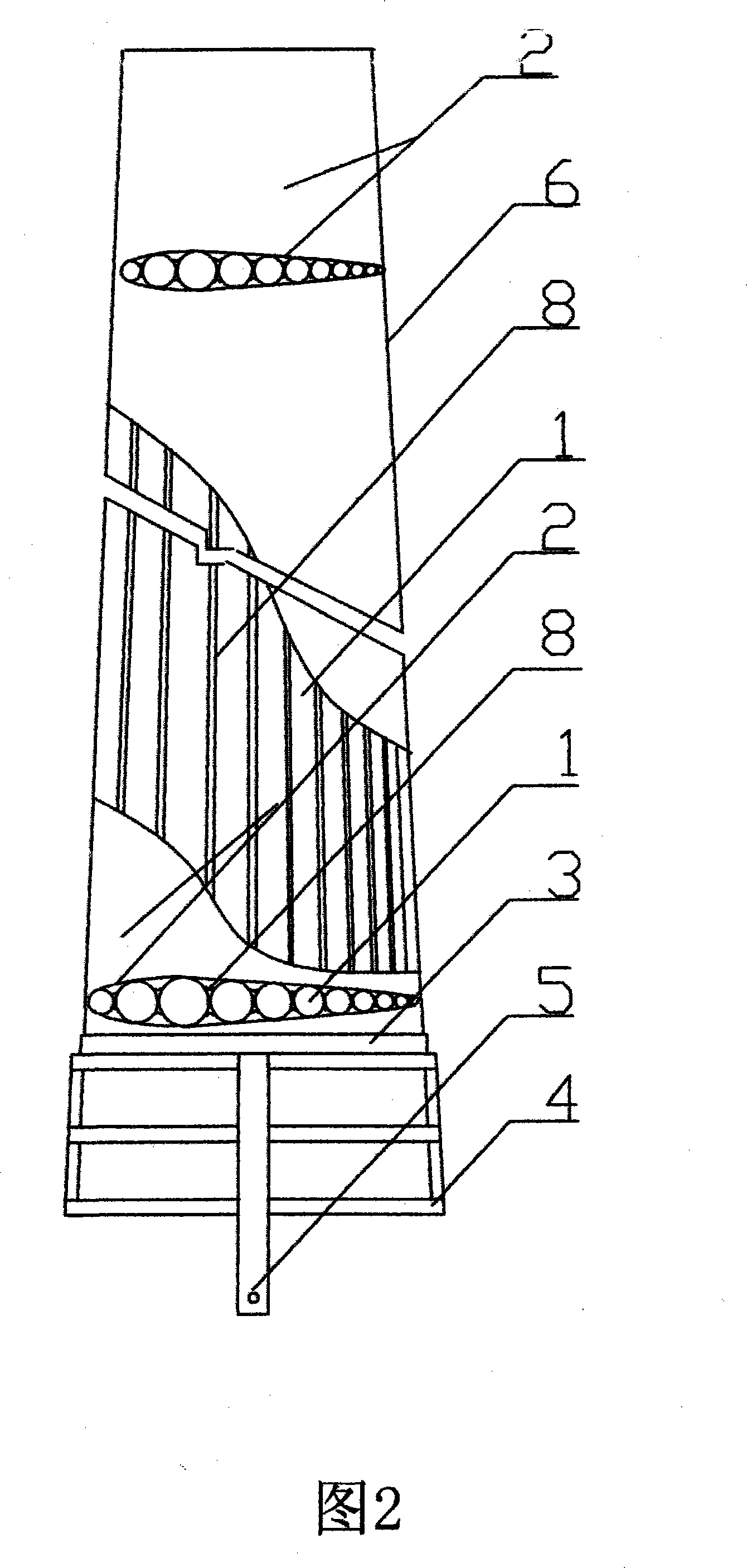

[0057] Embodiment 1: Strengthen the airfoil inflatable skeleton structure blade (as shown in Figure 2)

[0058] The reinforced airfoil inflatable skeleton structure blades have the same basic structure as the symmetrical airfoil inflatable skeleton structure blades shown in Figure 1, and their inflatable skeleton structures 1 are all formed by bonding or welding the inflatable skeletons, and can be made symmetrical Airfoil inflatable skeleton structure blades, and asymmetric airfoil inflatable skeleton structure blades; can be made into rigid inflatable skeleton structure blades, and can also be made into flexible inflatable skeleton structure blades; the difference is that to strengthen the inflatable skeleton structure Connection strength, between the two inflatable skeletons, add a double-arc-shaped reinforcing bracket 8 to increase the bonding or welding area between the inflatable skeletons, and strengthen the mechanical strength of the inflatable skeleton structure 1 . O...

Embodiment 2

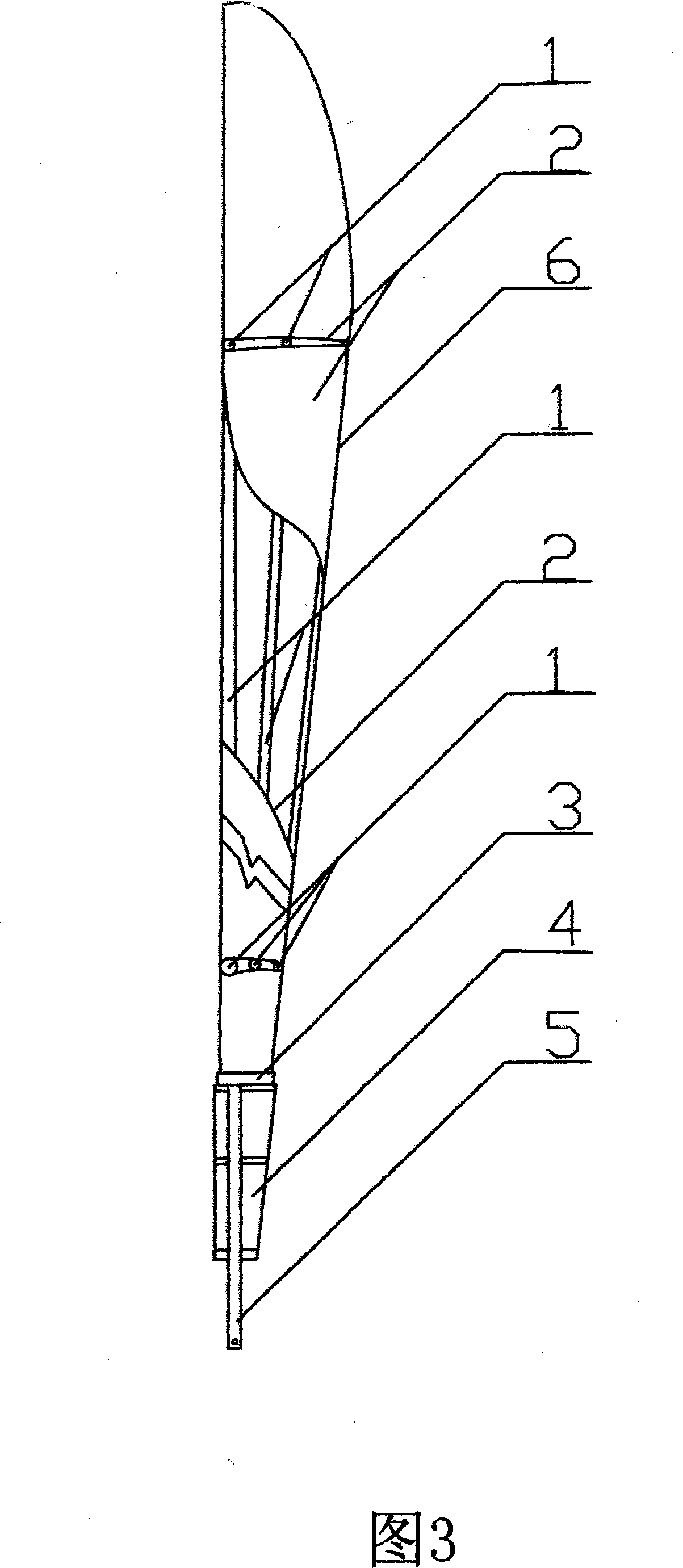

[0060] Embodiment 2: Ray airfoil inflatable skeleton structure blade (as shown in Figure 3)

[0061] The ray airfoil inflatable skeleton structure blade, its inflatable skeleton is a bit like the structure of the asymmetrical large feather skeleton of the wing when the bird spreads its wings, and they are also the ray distribution. At one end of the head of the ray airfoil inflatable skeleton structure 1, the inflatable skeletons can be bonded or welded together to form an overall inflatable skeleton structure to fix the structural position of each inflatable skeleton in the ray airfoil inflatable skeleton structure. Since the ray structure of the inflatable skeleton is closer to the tip of the blade, the distance between the skeletons is greater, and the area of the blade supported by each inflatable skeleton is also larger. The structural strength of each inflatable skeleton depends on its own strength. It is supported by the overall structure at one end of the head of the...

Embodiment 3

[0065] Embodiment 3: dragonfly airfoil inflatable skeleton structure blade (as shown in Figure 4)

[0066] The dragonfly airfoil-shaped air-skeleton structure blade refers to a thin blade with the same structure as a dragonfly wing. The dragonfly wing-shaped inflatable skeleton structure blade is a flexible inflatable skeleton structure blade made of composite film materials. Of course, the rigid air-filled frame structure blade can also be made of rigid composite thin materials.

[0067] The inflatable skeleton structure 1 of the blade is not composed of straight inflatable skeletons, but an interrelated network inflatable skeleton structure. If the inflatable skeleton structure 1 is simulated, the skeleton structure is relatively complicated, but due to the use of glue printing It is not difficult to produce dragonfly airfoil inflatable skeleton structure blades, so the inflatable skeleton structure 1 of dragonfly airfoil inflatable skeleton structure blade, the inflatable sk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com