Gear ring pump

A technology of internal gear pump and ring gear, which is applied to pumps, pump components, rotary piston pumps, etc., can solve the problems affecting the working reliability and service life of internal gear pumps, and reduce the phenomenon of strain and occlusion. High volumetric efficiency and improved friction characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

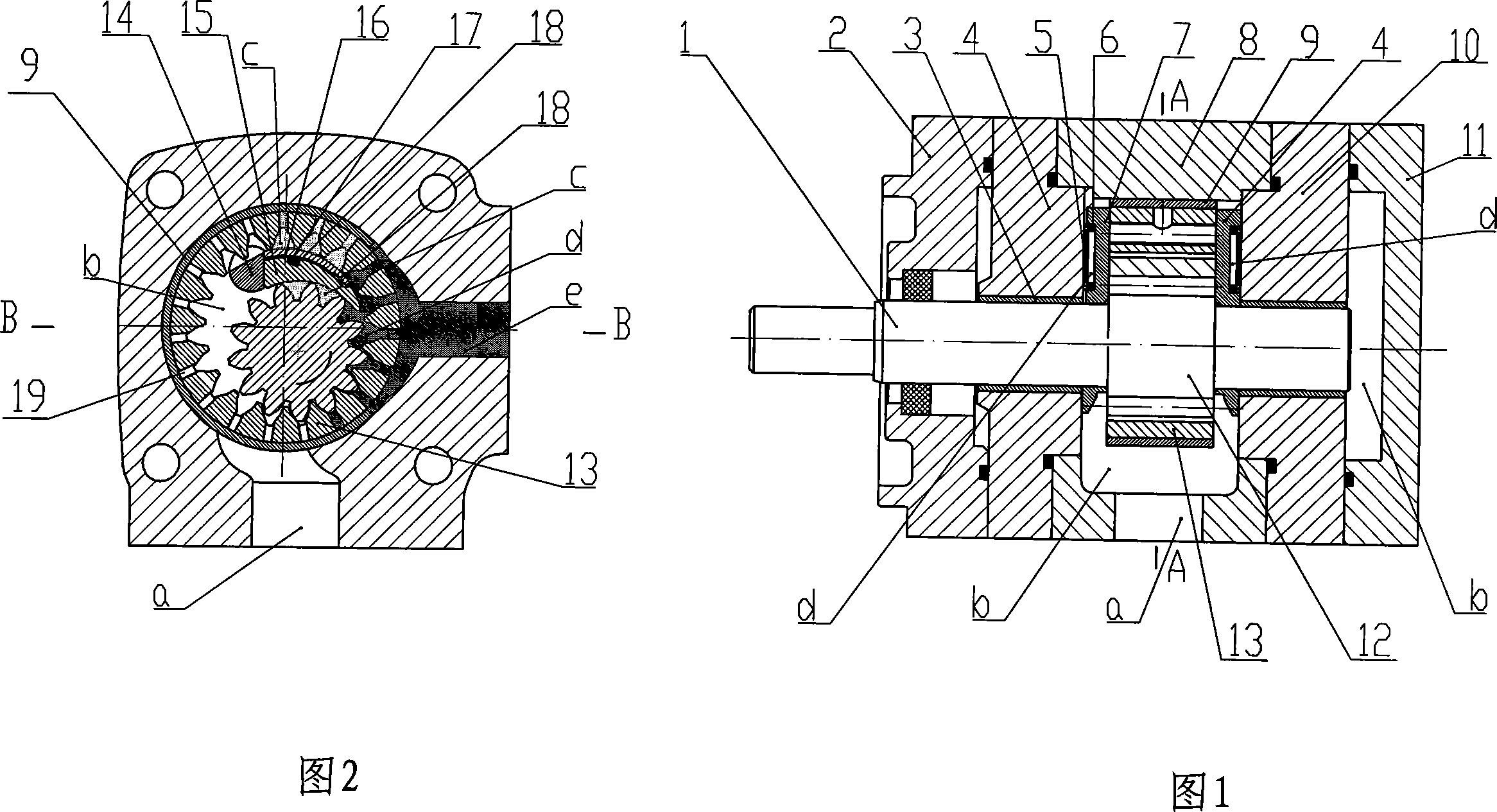

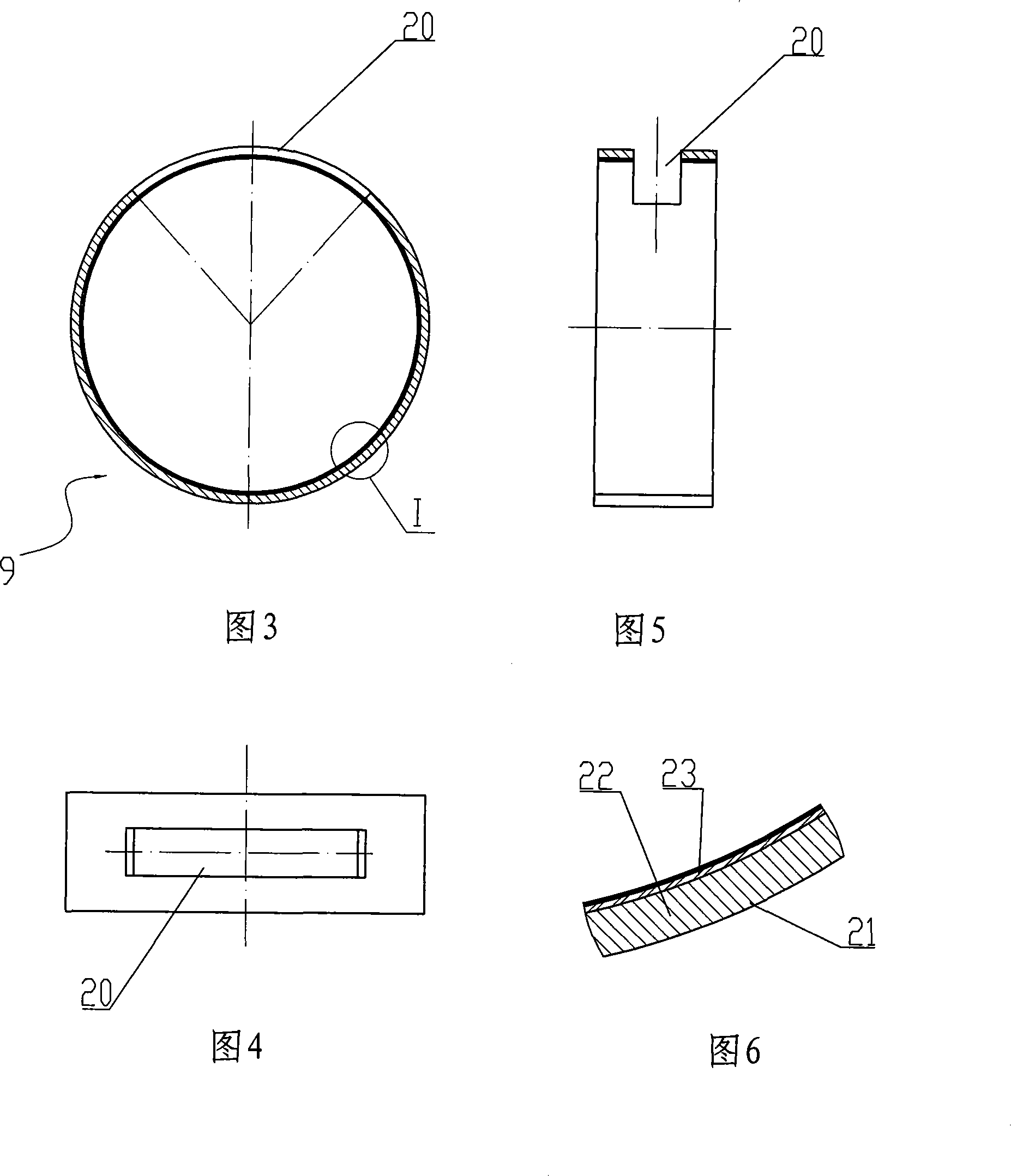

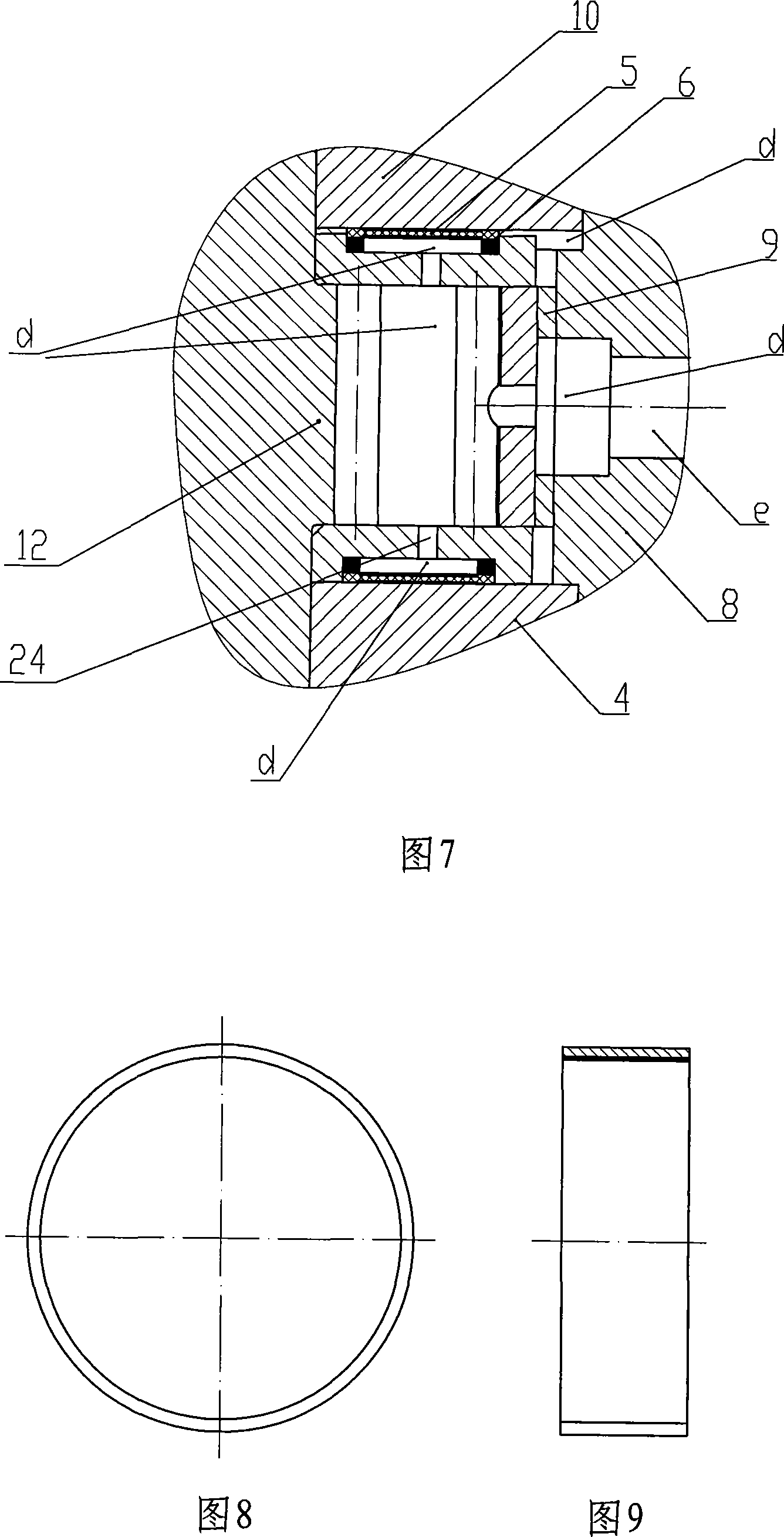

[0027] Embodiment 1: As shown in Figures 1 to 7, the internal gear pump includes a housing with an oil inlet a, an oil outlet e and an inner cavity, and a composite bush 9 in the inner cavity, an inner ring gear 13. The pinion gear 12 positioned on the transmission shaft 1, wherein the casing includes the pump body 8, the front support plate 4, the rear support plate 10, the front end cover 2, and the rear end cover 11 located at the front and back of the pump body 8. The inner cavity is surrounded by the pump body and the front and rear support plates, and the above-mentioned oil inlet a and oil outlet e are located on the pump body 8 .

[0028] The transmission shaft 1 and the pinion 12 are designed as one piece, and the transmission shaft 1 is supported on the front support disc 4 and the rear support disc 10 through the bearing 3 to ensure the reliable rotation of the pinion 12 . Here, the above-mentioned bearing 3 adopts a self-lubricating sliding composite bearing made o...

Embodiment 2

[0036] Embodiment 2, as shown in Fig. 8 and Fig. 9, differs from the above-mentioned first embodiment in that the internal gear pump is a structure with oil inlet and outlet on both sides of the inner ring gear, and at this time, the composite bushing is There is no need to open an oil port, which is a common shaft sleeve structure.

Embodiment 3

[0037] The third embodiment, as shown in Fig. 10 to Fig. 12, differs from the above-mentioned first embodiment in that the internal gear pump is a structure in which the inner ring gear radially discharges oil and radially enters oil. At this time, the composite lining The sleeve 9 is provided with an oil outlet 20 corresponding to the above-mentioned oil outlet hole e of the pump body and an oil inlet 25 corresponding to the above-mentioned oil inlet hole of the pump body.

[0038] At the same time, in order to utilize the oil at the oil inlet and the oil outlet to act on the ring gear, the oil outlet 20 and the oil inlet 25 are designed to be rectangular, and the widths of the rectangular oil outlet and the rectangular oil inlet are respectively greater than The diameter of the radial oil hole and the expanded length of the rectangular oil outlet are both 1 / 5 to 1 / 3 of the circumference of the inner ring gear. Its working principle is the same as that of the above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com